loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ม.ค. . 09, 2025 13:42

Back to list

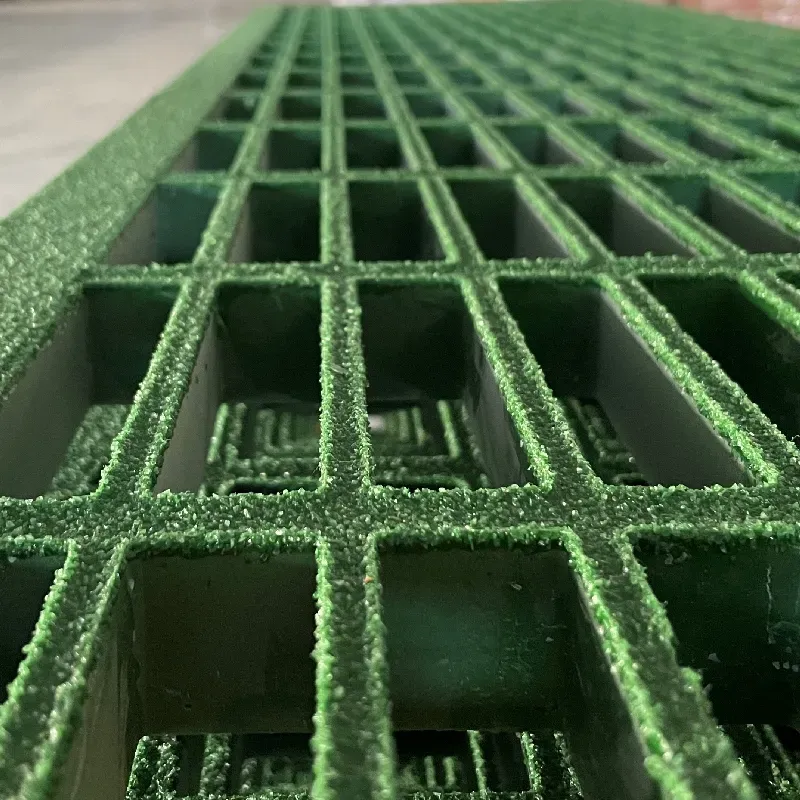

frp micro mesh grating

FRP micro mesh grating is revolutionizing industries with its versatile applications and unmatched durability. Companies in sectors such as industrial processing, marine, and construction are increasingly adopting this innovative material. A tangible experience of its benefits can be seen in the wastewater treatment industry. Here, FRP micro mesh grating is frequently used for walkways and platforms, providing a safe environment free from the risk of corrosion and electrical conductivity, thereby safeguarding employees and reducing maintenance costs.

In practical applications, FRP micro mesh grating is adeptly utilized in drain cover systems. Its lightweight nature compared to metal gratings facilitates easy installation and inspection without the need for heavy lifting equipment. This performance feature accelerates maintenance procedures, minimizing downtime. Utilizing non-slip surface options within FRP micro mesh provides an additional layer of safety in slippery environments, making it a preferred choice for enhancing workplace safety protocols. Manufacturers and suppliers continue to innovate, introducing features such as customizable colors and sizes, which cater to aesthetic and dimensional preferences, while maintaining structural harmony with existing facilities. This adaptability is particularly advantageous in projects where integration with other materials is paramount. For a successful implementation, consulting with a trusted supplier who provides technical support and customized solutions tailored to your specific project needs is crucial. By engaging with experts who understand the nuances of FRP micro mesh grating, companies can leverage its full potential, ensuring robust safety measures and optimized performance metrics across various applications. In conclusion, FRP micro mesh grating stands as a testament to modern engineering advancements, offering practical and enduring solutions for industrial challenges. Its blend of expertise, authority, and trust continues to redefine resilience and efficiency, making it an essential component in current and future infrastructure environments.

In practical applications, FRP micro mesh grating is adeptly utilized in drain cover systems. Its lightweight nature compared to metal gratings facilitates easy installation and inspection without the need for heavy lifting equipment. This performance feature accelerates maintenance procedures, minimizing downtime. Utilizing non-slip surface options within FRP micro mesh provides an additional layer of safety in slippery environments, making it a preferred choice for enhancing workplace safety protocols. Manufacturers and suppliers continue to innovate, introducing features such as customizable colors and sizes, which cater to aesthetic and dimensional preferences, while maintaining structural harmony with existing facilities. This adaptability is particularly advantageous in projects where integration with other materials is paramount. For a successful implementation, consulting with a trusted supplier who provides technical support and customized solutions tailored to your specific project needs is crucial. By engaging with experts who understand the nuances of FRP micro mesh grating, companies can leverage its full potential, ensuring robust safety measures and optimized performance metrics across various applications. In conclusion, FRP micro mesh grating stands as a testament to modern engineering advancements, offering practical and enduring solutions for industrial challenges. Its blend of expertise, authority, and trust continues to redefine resilience and efficiency, making it an essential component in current and future infrastructure environments.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025