loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ม.ค. . 14, 2025 09:51

Back to list

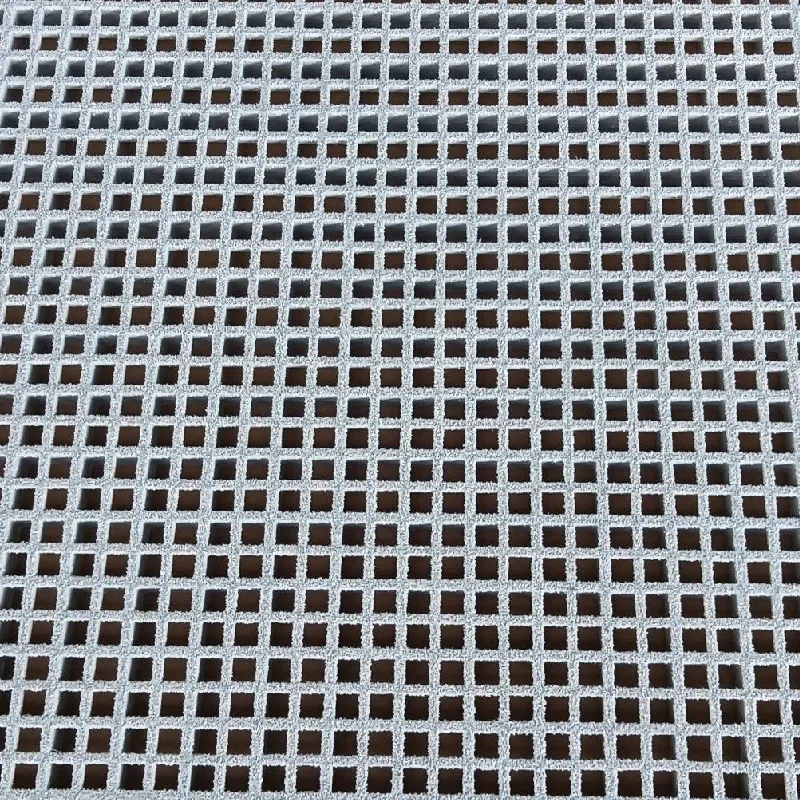

floor grating

Floor grating may seem like just another industrial product, but its importance in safety, durability, and design flexibility cannot be overstated. As industry experts will tell you, the right floor grating not only enhances operational efficiency but also adheres to the highest safety standards. My extensive experience in industrial flooring solutions allows me to provide first-hand insights into why expertly chosen floor grating should be at the top of any facility manager’s priority list.

Floor grating can also be customized to fit a variety of applications, ranging from industrial warehouses to sophisticated architectural designs. The versatility in sizing, load capacity, and aesthetic options makes floor grating an adaptable solution that can be tailored to specific needs. This customization enhances both functionality and visual appeal, allowing facilities to maintain an attractive yet practical environment. Trustworthiness in product quality is bolstered through certifications and adherence to international safety standards. Reputable manufacturers provide guarantees for their products, offering peace of mind and assurance of quality. As someone deeply embedded in the industry, I advise seeking out suppliers committed to compliance with standards like ISO and ANSI, which serve as badges of their commitment to safety and quality assurance. Ultimately, floor grating is more than a mere purchase; it is an investment in safety, efficiency, and durability. By combining experiential insights with meticulous selection processes and professional installation, facility managers can optimize both the performance and cost-effectiveness of their flooring solutions. Choose wisely, and your operations will reflect your diligence and dedication to excellence.

Floor grating can also be customized to fit a variety of applications, ranging from industrial warehouses to sophisticated architectural designs. The versatility in sizing, load capacity, and aesthetic options makes floor grating an adaptable solution that can be tailored to specific needs. This customization enhances both functionality and visual appeal, allowing facilities to maintain an attractive yet practical environment. Trustworthiness in product quality is bolstered through certifications and adherence to international safety standards. Reputable manufacturers provide guarantees for their products, offering peace of mind and assurance of quality. As someone deeply embedded in the industry, I advise seeking out suppliers committed to compliance with standards like ISO and ANSI, which serve as badges of their commitment to safety and quality assurance. Ultimately, floor grating is more than a mere purchase; it is an investment in safety, efficiency, and durability. By combining experiential insights with meticulous selection processes and professional installation, facility managers can optimize both the performance and cost-effectiveness of their flooring solutions. Choose wisely, and your operations will reflect your diligence and dedication to excellence.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025