loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

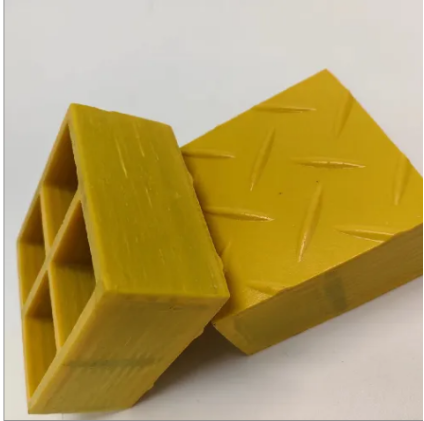

Covered Grating FRP Safety Features

Covered grating FRP—including its practical counterpart grating cover FRP—redefines safety in industrial, commercial, and public spaces by combining the durability of FRP with protective designs that mitigate common hazards like falls, debris accumulation, and chemical exposure. ZJ Composites, a global leader in composite materials with an unwavering focus on quality and innovation, empowers wholesalers to supply top-tier covered grating FRP solutions that meet rigorous safety standards worldwide. Backed by perfect testing equipment, strong technical support, and a product portfolio spanning FRP grating, pultrusion profiles, and pressure vessels, ZJ Composites has earned global trust—its covered grating FRP and grating cover FRP are sold across continents and supported by a customer service tenet centered on meeting client needs with safe, reliable solutions. Unlike traditional uncovered metal grating (prone to falls) or solid concrete (heavy and hard to maintain), ZJ’s covered grating FRP balances slip resistance, impact protection, and accessibility—making it ideal for walkways, platforms, and public areas where safety is non-negotiable. For wholesalers catering to construction firms, industrial facilities, or public infrastructure projects, partnering with ZJ Composites means accessing covered grating FRP that doesn’t just meet safety codes—it creates safer environments for end-users.

Fall Prevention The Core Safety Feature of Covered Grating FRP

- Solid Cover Design Eliminates Gap Hazards: Traditional uncovered grating has gaps that pose fall risks (e.g., tools, small objects, or even fingers getting caught), but covered grating FRP from ZJ Composites features a solid, non-slip top layer that covers these gaps entirely. The cover is bonded to the FRP grating base during production, creating a seamless surface that prevents falls through the grating—critical for elevated platforms or walkways in factories or commercial buildings. For example, a ZJ covered grating FRP installed in a warehouse mezzanine eliminates the risk of boxes or tools falling through to the floor below, protecting workers and inventory. Wholesalers can highlight this to clients, as gap elimination is the most direct way covered grating FRP enhances safety.

- Non-Slip Surface for All Weather Conditions: ZJ’s grating cover FRP is treated with a textured, gritty surface coating that maintains high friction even when wet, oily, or covered in snow. This coating is integrated into the FRP matrix (not just applied as a top layer), so it doesn’t peel or wear off over time—unlike adhesive non-slip tapes. Tests show ZJ’s covered grating FRP has a coefficient of friction (COF) of 0.65+ in wet conditions (well above the 0.5 threshold for “high slip resistance”), making it safe for outdoor areas like park walkways or industrial loading docks that face rain or snow. Wholesalers can emphasize this to clients, as non-slip performance is a year-round safety necessity.

Key Safety Features of ZJ Composites’ Grating Cover FRP

|

Safety Feature |

Details for Covered Grating FRP |

Ideal Application Scenarios |

ZJ Composites’ Production Edge |

Wholesaler Value (Market Fit) |

|

Fall Protection |

Solid cover eliminates gaps; 100% fall-through prevention; raised edge (optional) for extra barrier |

Elevated industrial platforms, commercial mezzanines |

Seamless cover-grating bonding; no loose components |

Caters to industrial distributors needing fall-safe solutions |

|

Chemical Resistance |

FRP material + chemical-resistant resin; repels acids, oils, and solvents—no degradation or leaks |

Chemical plant walkways, laboratory floors |

Custom resin blends (e.g., vinyl ester for harsh chemicals) |

Fits clients in high-spill, corrosive environments |

|

Impact Resistance |

Reinforced FRP cover withstands heavy impacts (e.g., dropped tools, foot traffic); no cracking |

Warehouse loading docks, manufacturing facility floors |

High-strength fiberglass core; thickened cover layer |

Appeals to construction firms needing durable, low-maintenance safety |

|

Fire Retardancy |

Optional fire-retardant resin; self-extinguishes (UL94 V-0 rating); low smoke emission |

Power plants, commercial kitchen floors, public buildings |

Fire-testing in in-house labs; compliance with global codes |

Helps wholesalers serve fire-safety-focused sectors |

|

Accessibility |

Smooth surface (meets ADA standards); optional drainage holes for water runoff; lightweight for easy installation |

Public parks, wheelchair-accessible walkways, hospitals |

ADA-compliant texture; customizable drainage design |

Caters to public infrastructure distributors needing inclusive safety |

Hazard Mitigation With Covered Grating FRP

- Chemical and Fluid Spill Protection: In industrial settings like chemical plants or laboratories, spills are a common hazard—but ZJ’s covered grating FRP acts as a barrier against chemical damage. The solid cover prevents spills from seeping into the grating’s base (where chemicals could accumulate and corrode components), and the FRP material itself resists degradation from acids, oils, or solvents. For example, a ZJ grating cover FRP installed in a battery manufacturing facility will contain acid spills, preventing them from reaching the floor below and causing slips or equipment damage. Wholesalers can highlight this to clients, as spill containment reduces both safety risks and cleanup costs.

- Debris and Pest Prevention: Uncovered grating often traps debris (like dirt, leaves, or small parts) that can cause clogs, attract pests, or create trip hazards—but covered grating FRP’s solid surface keeps debris out. For outdoor applications like stadium walkways or park paths, this means less maintenance (no need to clean out grating gaps) and fewer pest infestations (no debris for rodents to nest in). In food processing plants, ZJ’s covered grating FRP also prevents food particles from falling into gaps, maintaining hygiene and complying with food safety standards (e.g., FDA regulations). Wholesalers can market this to clients, as debris prevention cuts down on maintenance time and hygiene-related risks.

Installation and Maintenance for Safe Covered Grating FRP Use

- Proper Installation for Structural Safety: ZJ’s covered grating FRP is designed for easy, safe installation—lightweight (75% lighter than steel covered grating) so it requires no heavy lifting equipment, and pre-drilled holes for fasteners that ensure a secure fit. ZJ recommends using its compatible FRP fasteners (corrosion-resistant, matching the grating) to avoid metal fasteners that could rust and weaken over time. For elevated platforms, ZJ also offers optional support brackets that reinforce the grating’s load capacity, ensuring it can withstand heavy foot traffic or equipment. Wholesalers can include installation guides with bulk orders, helping clients avoid common mistakes (like under-tightening fasteners) that could compromise safety.

- Minimal Maintenance to Preserve Safety Features: Covered grating FRP from ZJ needs almost no maintenance to retain its safety performance—occasional cleaning with soap and water removes debris or spills, and no painting, rust treatment, or part replacement is required. Unlike steel covered grating that rusts or wood that rots, ZJ’s grating cover FRP maintains its safety features for 15–20 years with basic care. For example, a covered grating FRP walkway in a school will stay slip-resistant and fall-safe for decades, with only annual cleaning needed. Wholesalers can share this with clients, as low maintenance means long-term safety without ongoing costs.

Covered Grating FAQS

Does ZJ’s Covered Grating FRP Meet Global Safety Standards?

Yes—ZJ’s covered grating FRP complies with international safety standards like OSHA (U.S.) for fall protection, ADA (U.S.) for accessibility, UL94 V-0 (global) for fire retardancy, and ISO 14122 (global) for structural safety. Each batch is tested in ZJ’s labs to confirm compliance—for example, fall-through testing ensures no objects or body parts can pass through the grating, and slip-resistance testing verifies COF ratings. Wholesalers can confirm specific standards for clients in target markets, ensuring the grating meets local safety regulations.

Can Grating Cover FRP Be Customized for Specific Safety Needs?

Absolutely—ZJ Composites offers custom grating cover FRP for bulk orders, including options like fire-retardant resin (for high-fire-risk areas), raised edges (for extra fall protection), or drainage holes (for outdoor water runoff). For example, a client needing covered grating FRP for a marine dock can request saltwater-resistant resin and drainage holes to prevent water pooling. ZJ’s technical team works with clients to identify their unique safety hazards, then designs a grating that addresses those needs. Wholesalers can leverage this customization to serve niche clients with specialized safety requirements.

What Load Capacity Does ZJ’s Covered Grating FRP Have?

ZJ’s covered grating FRP has a standard load capacity of 500–1,000 kg/m² (suitable for foot traffic, wheelchairs, and light equipment), with heavy-duty variants available up to 2,000 kg/m² (for industrial areas with forklifts or heavy tools). The load capacity is tested and certified, ensuring it meets the needs of different applications—for example, a heavy-duty covered grating FRP for a warehouse loading dock can handle forklift traffic safely. Wholesalers can share load capacity charts with clients, helping them choose the right grating for their weight requirements.

Is Covered Grating FRP Suitable for Outdoor Use Year-Round?

Yes—ZJ’s covered grating FRP is designed for all-weather outdoor use: it resists UV damage (thanks to UV stabilizers in the resin), doesn’t freeze or crack in low temperatures (-20°C to 80°C standard range), and has optional drainage holes to prevent water or snow buildup. For outdoor applications like park walkways or stadium ramps, this means the grating stays safe and functional in rain, snow, or intense sunlight—no warping, fading, or slip risks. Wholesalers can market this to clients in outdoor sectors, as year-round durability eliminates seasonal safety concerns.

Does ZJ Composites Offer Bulk Shipping for Covered Grating FRP Globally?

Yes—ZJ Composites has extensive global shipping experience, with covered grating FRP and grating cover FRP delivered to regions like Europe, North America, Southeast Asia, and the Middle East. For wholesalers, ZJ provides specialized packaging (sturdy crates with foam padding) to prevent damage during transit, and partners with reliable logistics firms to ensure on-time delivery. The team also assists with customs documentation (e.g., safety certificates, material data sheets) to avoid delays. Wholesalers can rely on ZJ’s supply chain to meet large orders—whether for a public infrastructure project or an industrial facility overhaul—supporting their business growth. To explore ZJ Composites’ covered grating FRP, grating cover FRP, and full range of FRP products—plus bulk ordering and customization options—visit our company webpage today.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025