loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Affordable Options for Floor Grating Pricing in Construction and Renovation Projects

Understanding Floor Grating Prices A Comprehensive Overview

Floor grating is a crucial component in many industrial and commercial settings, providing safety, durability, and functionality. Whether used in platforms, walkways, or drainage systems, the choice of floor grating can significantly impact operational efficiency and safety standards. One of the critical factors that influence the selection of floor grating is its price. In this article, we will explore the various factors affecting floor grating prices, typical costs, and tips for choosing the right grating for your needs.

Factors Affecting Floor Grating Prices

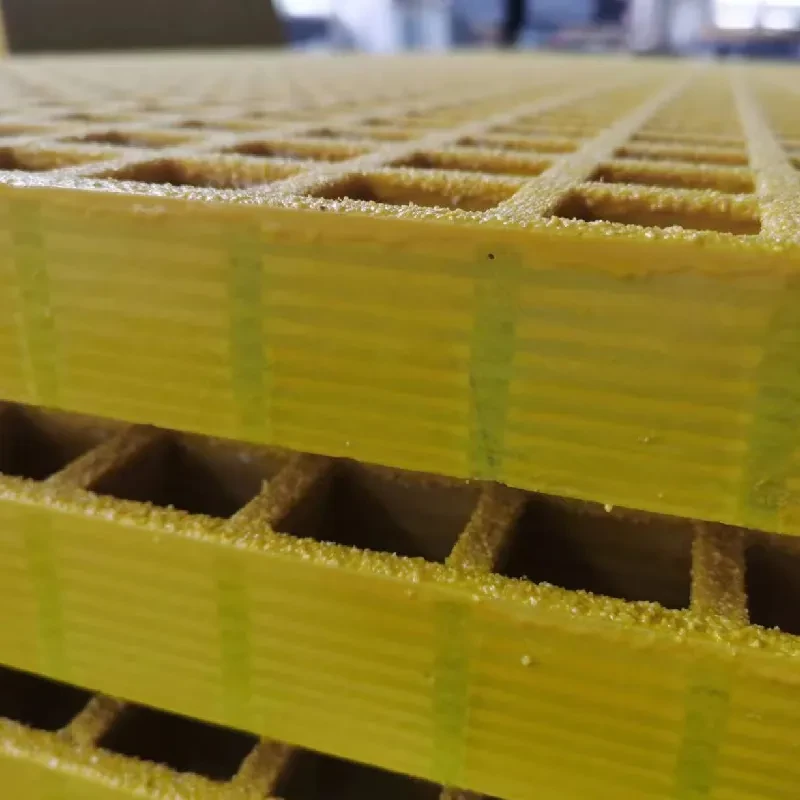

1. Material Selection The price of floor grating largely depends on the material used. Common materials include steel, aluminum, fiberglass, and plastic. Steel grating, particularly galvanized steel, is typically more affordable but may require more maintenance in corrosive environments. Aluminum grating is lighter and more resistant to corrosion but tends to be more expensive. Fiberglass grating, while often the most costly, offers excellent chemical resistance and durability.

2. Grating Type There are various types of floor grating, including welded, molded, and press-locked grating. Each type has its price range based on the manufacturing process and the strength it offers. For instance, welded grating is generally stronger and more durable but may come at a higher price point due to the complexity of production.

3. Load Capacity The load capacity of the grating is another factor that impacts the price. Heavy-duty grating capable of supporting substantial weight loads will typically be more expensive than standard options. It’s essential to assess the specific load requirements for your application to ensure that you select the appropriate grating type.

4. Size and Customization Custom sizes and designs can also drive up the price of floor grating. Standard sizes tend to be more cost-effective, while custom orders often involve additional manufacturing and logistical costs. Companies may choose custom grating to fit specific space requirements or to achieve aesthetic goals.

5. Surface Treatments The presence of surface treatments can influence the cost. For example, grating with non-slip surfaces or coatings for additional corrosion resistance will generally be pricier. However, these treatments can enhance safety and durability, potentially reducing long-term maintenance costs.

6. Supplier and Market Trends Prices can also vary significantly between different suppliers and manufacturers. It's advisable to compare prices from multiple sources and keep an eye on market trends, as fluctuations in raw material costs can impact pricing in real-time.

floor grating price

Typical Pricing Ranges

In general, floor grating prices can vary widely based on the factors outlined above. On average, steel grating may range from $3 to $12 per square foot, while aluminum grating can fall between $10 and $25 per square foot. Fiberglass grating typically starts around $20 and can exceed $50 per square foot depending on the specifications. Ultimately, the price will depend on the combination of material, type, load capacity, size, and any necessary treatments.

Tips for Choosing the Right Floor Grating

1. Assess Your Needs Evaluate the specific requirements of your application, such as load-bearing needs, environmental conditions, and desired aesthetics.

2. Consider Long-Term Costs While upfront costs are important, consider the long-term maintenance and replacement costs associated with different materials and treatments.

3. Get Multiple Quotes Always seek quotes from multiple suppliers to find the best price and value for your chosen specifications.

4. Consult Professionals If in doubt, consult with engineers or procurement specialists who can provide insights on the best choices for your particular situation.

Conclusion

Floor grating is an essential component in ensuring safety and efficiency in various environments. Understanding the factors that affect floor grating prices can help businesses make informed purchasing decisions. By considering material, type, load capacity, and customization needs, you can ensure that you select the right grating for your application while remaining mindful of costs. Ultimately, investing in quality floor grating not only enhances safety but can also lead to long-term savings in maintenance and replacement costs.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025