loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

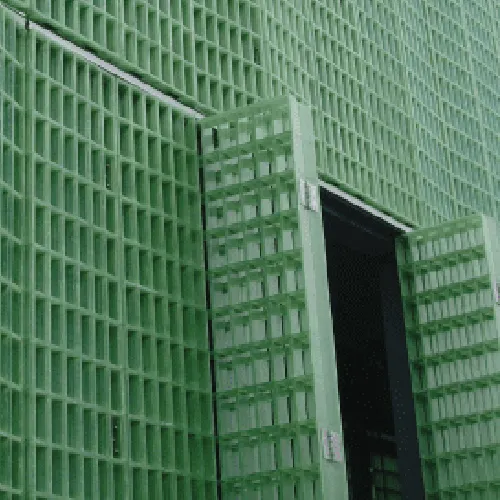

fibreglass mesh grating

Exploring Fiberglass Mesh Grating A Versatile Solution for Various Applications

Fiberglass mesh grating is a remarkable material that has gained immense popularity across various industries due to its unique properties and versatile applications. Composed of a combination of fiberglass and resin, this type of grating offers a lightweight yet robust alternative to traditional metal grating. Its durability, corrosion resistance, and ease of installation make it an ideal choice for numerous settings, from industrial environments to commercial spaces.

Understanding Fiberglass Mesh Grating

At its core, fiberglass mesh grating consists of woven fiberglass strands impregnated with a thermosetting resin. The manufacturing process creates a matrix that provides structural strength and resilience. The grating can be molded into various shapes and sizes, making it adaptable to different requirements. One of the primary benefits of fiberglass mesh grating is its inherent resistance to the elements. Unlike metal, it does not rust or corrode when exposed to chemicals or moisture, which makes it particularly suitable for wet or corrosive environments.

Key Benefits

1. Corrosion Resistance Fiberglass is immune to the corrosive effects of saltwater, certain acids, and other chemical substances. This property makes it an excellent choice for marine applications and chemical plants where other materials might fail.

2. Lightweight and Strong Despite its lightweight nature, fiberglass mesh grating can support heavy loads, making it suitable for both pedestrian and vehicular traffic. This characteristic not only simplifies installation but also reduces transportation costs.

3. Non-Conductive For applications where electrical conductivity is a concern, fiberglass grating provides a safe alternative. It’s non-conductive, making it ideal for electrical and telecommunication installations.

4. Low Maintenance The smooth surface of fiberglass grating minimizes debris accumulation and is easy to clean, leading to lower maintenance costs and extended lifespan.

5. Versatility Available in various colors and sizes, fiberglass mesh grating can be tailored to meet specific design requirements. It can be easily fabricated to create custom shapes, making it suitable for a wide range of applications.

fibreglass mesh grating

Applications of Fiberglass Mesh Grating

The versatility of fiberglass mesh grating allows its use in numerous sectors

- Industrial Facilities In manufacturing plants, fiberglass grating is often used for flooring, walkways, and platforms due to its high load-bearing capacity and slip resistance.

- Wastewater Treatment Plants The material's resistance to corrosion makes it a favorite in environments dealing with harsh chemicals and constant moisture. It is commonly used in trench covers, access platforms, and stair treads.

- Marine Environments Fiberglass grating is extensively used in docks and piers, where exposure to saltwater and high humidity can lead to the rapid deterioration of traditional materials.

- Pharmaceuticals and Food Processing In cleanroom environments, fiberglass grating helps maintain hygiene standards due to its ability to withstand frequent cleaning and disinfection without degrading.

- Commercial Spaces From supermarkets to shopping malls, fiberglass mesh grating is used in floor systems where aesthetics and safety are paramount.

Conclusion

Fiberglass mesh grating stands out as a multipurpose material that addresses challenges faced by various industries. Its exceptional properties—corrosion resistance, lightweight, non-conductive nature, and low maintenance—position it as a superior choice compared to traditional metal options. As industries continue to prioritize both functionality and safety, fiberglass grating is set to play a crucial role in modern construction and infrastructure development. The continual advancements in fiberglass technology will likely lead to even more innovative applications, making this material a staple in future projects.

-

the-expansive-industrial-reign-of-frp-pressure-vesselsNewsAug.22,2025

-

manufacturing-premium-frp-square-pipes-for-global-wholesale-excellenceNewsAug.22,2025

-

strategic-applications-for-frp-grating-solutionsNewsAug.22,2025

-

material-science-forging-grp-water-tank-longevityNewsAug.22,2025

-

the-engineered-excellence-material-science-behind-frp-railing-systemsNewsAug.22,2025

-

how-digital-pultrusion-revolutionizes-frp-profile-wholesalingNewsAug.22,2025

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025