loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 13, 2025 15:25

Back to list

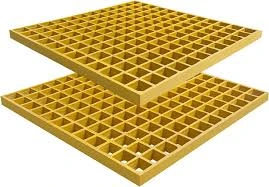

fiberglass reinforced plastic grating

Fiberglass Reinforced Plastic (FRP) Grating is transforming industries with its ingenious design, offering a blend of durability, strength, and versatility that outpaces traditional materials. Drawing from decades of industrial experience, this product is becoming the go-to solution for environments that demand resilience and reliability.

The authority of FRP grating in the marketplace is further reinforced by compliance with global safety standards. Renowned for its quality and performance, FRP grating is manufactured to meet rigorous standards, such as those set by ASTM International, to ensure superior safety and performance. This compliance confirms its credibility and reassures industries of its suitability for challenging applications. Trust in FRP grating also comes from successful, real-world applications across multiple industries. For instance, in oil and gas platforms, where exposure to harsh marine environments is a daily challenge, operators have adopted FRP grating due to its proven ability to endure while ensuring safety underfoot. Similarly, wastewater treatment plants have chosen FRP grating to combat corrosion and extend the lifespan of their infrastructure. These testamentary applications underscore the trust that industries place in FRP grating, owing to its proven track record in harsh conditions. In conclusion, fiberglass reinforced plastic grating is setting new benchmarks by offering an unrivaled combination of durability, safety, and cost-effectiveness. With its robust performance in harsh and demanding environments, it presents a future where industrial applications can confidently lean on a material that embodies both innovation and reliability. As industries continue to evolve, the role of FRP grating in providing sustainable and effective solutions is indisputable, making it an invaluable asset in the industrial materials sector.

The authority of FRP grating in the marketplace is further reinforced by compliance with global safety standards. Renowned for its quality and performance, FRP grating is manufactured to meet rigorous standards, such as those set by ASTM International, to ensure superior safety and performance. This compliance confirms its credibility and reassures industries of its suitability for challenging applications. Trust in FRP grating also comes from successful, real-world applications across multiple industries. For instance, in oil and gas platforms, where exposure to harsh marine environments is a daily challenge, operators have adopted FRP grating due to its proven ability to endure while ensuring safety underfoot. Similarly, wastewater treatment plants have chosen FRP grating to combat corrosion and extend the lifespan of their infrastructure. These testamentary applications underscore the trust that industries place in FRP grating, owing to its proven track record in harsh conditions. In conclusion, fiberglass reinforced plastic grating is setting new benchmarks by offering an unrivaled combination of durability, safety, and cost-effectiveness. With its robust performance in harsh and demanding environments, it presents a future where industrial applications can confidently lean on a material that embodies both innovation and reliability. As industries continue to evolve, the role of FRP grating in providing sustainable and effective solutions is indisputable, making it an invaluable asset in the industrial materials sector.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025