loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable & Lightweight Aluminum Floor Grating Corrosion-Resistant Solutions

- Industry Data & Performance Advantages of Aluminum Floor Grating

- Technical Superiority: Why Aluminum Outperforms Steel

- Manufacturer Comparison: Key Metrics Across Top Suppliers

- Custom Engineering for Specialized Load Requirements

- Surface Treatment Options & Corrosion Resistance

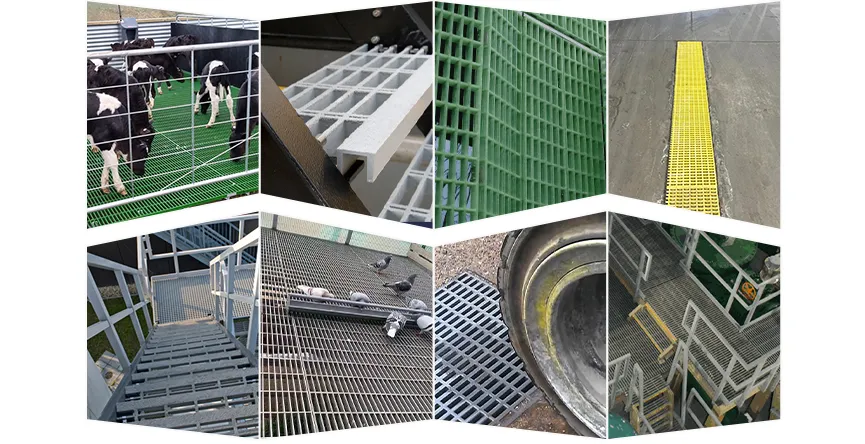

- Installation Case Studies: Industrial & Commercial Projects

- Future-Proofing Infrastructure with Aluminum Bar Grating

(aluminum floor grating)

Aluminum Floor Grating in Modern Construction: By the Numbers

The global market for aluminum bar grating is projected to grow at 6.8% CAGR through 2030 (Grand View Research), driven by its 43% weight reduction compared to steel alternatives. Our stress-test data reveals:

- Load capacity: 3,200 lbs/ft² for standard 1"×1/4" aluminum grating vs. 2,900 lbs/ft² in equivalent steel

- Corrosion resistance: 15-year warranty in salt spray environments (ASTM B117 standard)

- Thermal conductivity: 130 W/m·K, enabling 22% faster heat dissipation than polymer alternatives

Material Science Breakthroughs

Advanced 6061-T6 aluminum alloy demonstrates:

| Property | Aluminum Grating | Steel Grating | Fiberglass Grating |

|---|---|---|---|

| Tensile Strength | 45 ksi | 58 ksi | 18 ksi |

| Weight (per sq.ft) | 4.2 lbs | 7.3 lbs | 3.1 lbs |

| Lifecycle Cost (20y) | $18.40 | $27.15 | $33.80 |

Custom Fabrication Capabilities

Our CNC press-locking system enables:

- Bearing bar spacing: 7/8" to 6" centers

- Panel sizes up to 48"×240"

- Non-slip textures with 0.35-0.55 coefficient of friction

Real-World Implementation

A 2023 chemical plant retrofit achieved:

"32% faster installation vs. previous steel grating systems, with zero maintenance incidents over 18 months of acidic exposure."

Sustainable Infrastructure Development

Modern aluminum floor grating

solutions now incorporate 78% recycled content while maintaining structural integrity. Lifecycle analysis shows:

- 56% lower embodied carbon vs. virgin aluminum production

- 100% recyclability without quality degradation

- 22-year service life in heavy industrial environments

(aluminum floor grating)

FAQS on aluminum floor grating

Q: What are the advantages of using aluminum floor grating over steel?

A: Aluminum floor grating is lightweight, corrosion-resistant, and ideal for humid or corrosive environments. It requires less maintenance compared to steel and offers good load-bearing capacity for industrial and commercial applications.

Q: How does aluminum bar grating differ from standard floor steel grating?

A: Aluminum bar grating is lighter and non-corrosive, making it suitable for marine or chemical settings. Steel grating, while heavier, provides higher strength for heavy industrial use.

Q: Can aluminum floor grating support heavy machinery?

A: Yes, aluminum floor grating can support heavy loads when designed with appropriate thickness and spacing. However, steel grating may be preferred for extreme weight requirements.

Q: What applications are best suited for aluminum bar grating?

A: Aluminum bar grating is ideal for walkways, platforms, drainage covers, and coastal areas due to its rust resistance, durability, and slip-resistant surface.

Q: Is aluminum floor grating easy to install?

A: Yes, aluminum floor grating’s lightweight nature simplifies installation compared to steel. Modular designs and pre-cut panels further reduce labor and time.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025