loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ఫిబ్ర . 16, 2025 00:54

Back to list

Long Lasting Sanitary SMC FRP Storage Water Tank

Machine guarding systems play a pivotal role in ensuring workplace safety and operational efficiency. In today's highly automated industrial environment, these systems are indispensable, acting as a shield against potential hazards posed by machinery. Their importance goes beyond mere compliance with safety regulations, as they are critical in minimizing workplace injuries, reducing downtime, and enhancing productivity.

Authority in machine guarding systems is established through a commitment to industry standards and continuous improvement. Leading manufacturers of these systems work closely with regulatory bodies, such as OSHA in the United States and the Health and Safety Executive (HSE) in the UK, to ensure their products comply with current safety regulations. Additionally, these companies strive to set benchmarks within the industry, often participating in committees and contributing to the development of new safety protocols and guidelines. Trustworthiness is integral to the relationship between machine guarding system providers and their clients. Trust is built through transparent communication, reliable customer support, and demonstrable results. Testimonials and case studies from a diverse range of industries underscore the ability of these systems to deliver on their promises of enhanced safety and operational efficiency. Regular training sessions and updates ensure that clients remain informed about the best practices in machine safeguarding, further solidifying their faith in the product. Moreover, trustworthiness is reinforced by third-party certifications and endorsements, such as ISO certifications, which validate the quality and safety of these guarding systems. These certifications provide an additional layer of assurance, helping businesses to confidently choose solutions that align with their safety objectives and regulatory obligations. In conclusion, machine guarding systems are more than just a regulatory requirement; they are an essential component of modern industrial safety protocols. Through real-world experience, expert design, authoritative compliance with industry standards, and unwavering trustworthiness, these systems deliver unparalleled benefits. They protect lives, optimize operational efficiency, and ultimately contribute to a safer and more productive workplace. Investing in a robust machine guarding system is not merely a safety measure; it is a strategic decision that can lead to sustained business success and peace of mind for all stakeholders involved.

Authority in machine guarding systems is established through a commitment to industry standards and continuous improvement. Leading manufacturers of these systems work closely with regulatory bodies, such as OSHA in the United States and the Health and Safety Executive (HSE) in the UK, to ensure their products comply with current safety regulations. Additionally, these companies strive to set benchmarks within the industry, often participating in committees and contributing to the development of new safety protocols and guidelines. Trustworthiness is integral to the relationship between machine guarding system providers and their clients. Trust is built through transparent communication, reliable customer support, and demonstrable results. Testimonials and case studies from a diverse range of industries underscore the ability of these systems to deliver on their promises of enhanced safety and operational efficiency. Regular training sessions and updates ensure that clients remain informed about the best practices in machine safeguarding, further solidifying their faith in the product. Moreover, trustworthiness is reinforced by third-party certifications and endorsements, such as ISO certifications, which validate the quality and safety of these guarding systems. These certifications provide an additional layer of assurance, helping businesses to confidently choose solutions that align with their safety objectives and regulatory obligations. In conclusion, machine guarding systems are more than just a regulatory requirement; they are an essential component of modern industrial safety protocols. Through real-world experience, expert design, authoritative compliance with industry standards, and unwavering trustworthiness, these systems deliver unparalleled benefits. They protect lives, optimize operational efficiency, and ultimately contribute to a safer and more productive workplace. Investing in a robust machine guarding system is not merely a safety measure; it is a strategic decision that can lead to sustained business success and peace of mind for all stakeholders involved.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

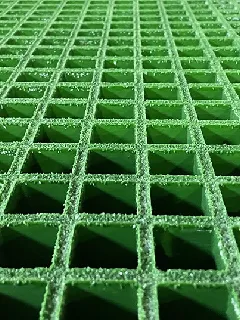

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025