loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Impact of Group Structures on Organizational Performance and Dynamics

Understanding GRP Structures A Comprehensive Overview

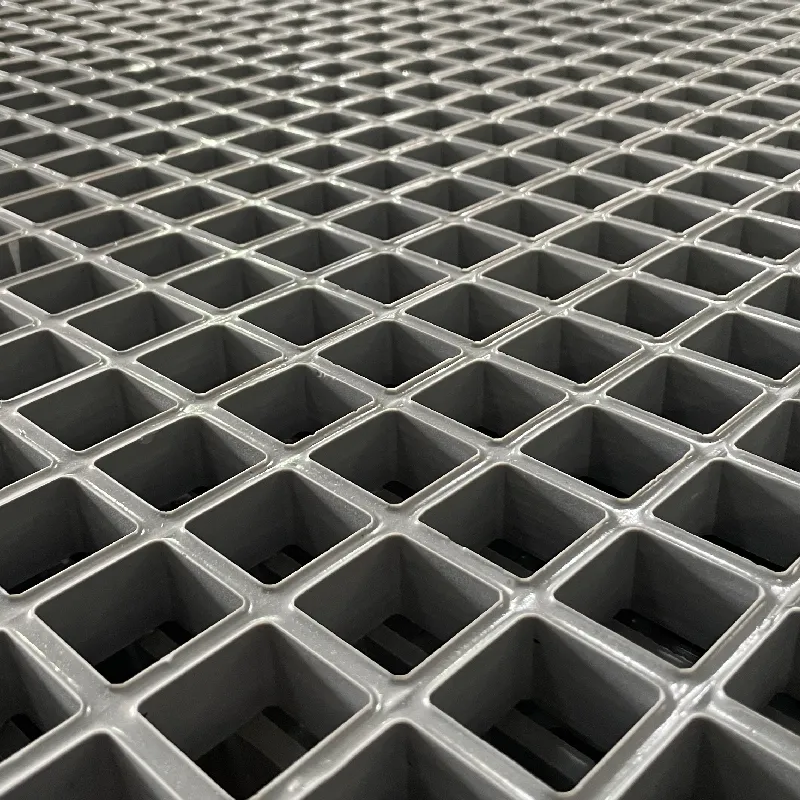

Glass Reinforced Plastic (GRP) structures, also known as fiberglass, are composite materials that have gained significant attention in various industries due to their unique properties and advantages. GRP combines the toughness of glass fibers with the versatility of plastic, resulting in a structure that is strong, lightweight, and resistant to a variety of environmental factors. This article will explore the characteristics, applications, and benefits of GRP structures, highlighting their importance in modern engineering and construction.

What is GRP?

GRP is created by embedding glass fibers in a polymer matrix, typically a thermosetting resin. This combination results in a composite material that exhibits exceptional strength and durability. The glass fibers provide tensile strength, while the resin offers flexibility and resistance to moisture, chemicals, and UV radiation. The manufacturing process of GRP can vary but often involves methods such as hand lay-up, spray-up, or filament winding, depending on the desired properties and applications of the final product.

Key Characteristics of GRP Structures

1. Lightweight One of the most appealing features of GRP is its lightweight nature. Compared to traditional materials such as steel or concrete, GRP can significantly reduce the overall weight of structures. This characteristic makes GRP an excellent choice for applications where weight savings are crucial, such as in aerospace or automotive industries.

2. Corrosion Resistance GRP is highly resistant to corrosion, making it suitable for a variety of harsh environments. It can withstand exposure to chemicals, saltwater, and other corrosive elements, which often degrade conventional materials over time. This property makes GRP a popular choice for industries involved in marine applications, chemical processing, and wastewater treatment.

3. Thermal Insulation GRP has excellent thermal insulation properties, which helps in maintaining temperature and reducing energy costs. This characteristic is particularly advantageous in the construction of energy-efficient buildings and facilities where climate control is essential.

grp structures

4. Design Flexibility The versatility of GRP allows for a wide range of design options. It can be molded into complex shapes and structures, providing architects and engineers with greater creative freedom. This flexibility also facilitates the integration of other materials or components, enhancing the overall performance of the structure.

Applications of GRP Structures

The applications of GRP are vast and diverse. In the construction industry, GRP is commonly used for cladding, roofing, and structural elements, providing a combination of aesthetics and functionality. In marine applications, GRP is utilized for boat hulls, deck fittings, and other components due to its lightweight and corrosion-resistant properties. Other notable applications include Electrical enclosures, tanks, bridges, and even sporting equipment, reflecting its versatility.

Benefits of GRP Structures

The advantages of using GRP structures extend beyond their inherent properties. The durability and low maintenance requirements of GRP can result in significant cost savings over time. The lifespan of GRP components is often longer than that of traditional materials, reducing the need for frequent replacements. Furthermore, the lightweight nature of GRP facilitates easier transportation and installation, leading to lower labor costs and shorter project timelines.

Conclusion

In conclusion, GRP structures represent a significant advancement in materials science, offering unique benefits that enhance performance across various applications. Their lightweight, corrosion-resistant, and thermally insulated nature makes GRP an ideal choice in industries where traditional materials may fall short. As technology continues to evolve, the use of GRP is likely to expand, paving the way for innovative designs and applications that push the boundaries of engineering and construction. Embracing GRP technology can lead to more sustainable, efficient, and aesthetically pleasing solutions in an increasingly demanding world.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025