loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

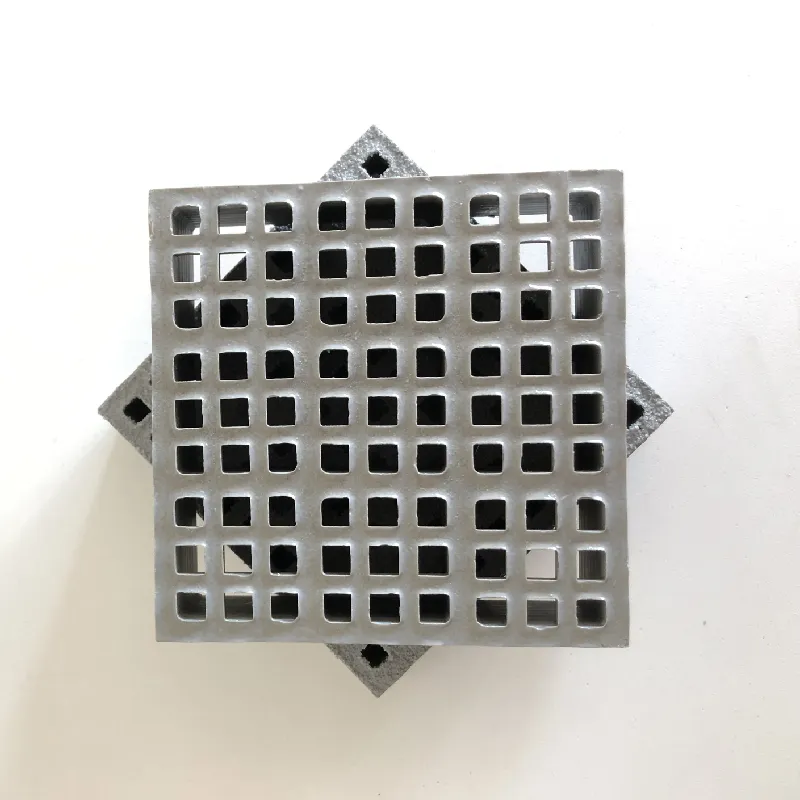

welded bar grating

Understanding Welded Bar Grating Applications and Advantages

Welded bar grating is an essential structural element that offers numerous advantages in a variety of industrial and commercial applications. Composed of a series of bearing bars welded together with cross bars at regular intervals, this type of grating exemplifies both strength and versatility. It is commonly used in flooring, walkways, platforms, and drainage covers, among other functions.

Structure and Material

Welded bar grating is typically made from materials such as steel, aluminum, or fiberglass, depending on the specific requirements of the application. The most common is steel, due to its strength and durability. The manufacturing process involves taking flat bars and welding them at predetermined intervals, forming a lattice structure that allows for a variety of load-bearing capabilities while maintaining an open area for ventilation, light, and water drainage.

The bearing bars usually run in one direction, while the cross bars are welded perpendicularly, ensuring high load capacity and rigidity. This design allows for easy installation and maintenance, making it an attractive choice for various industries.

Applications

Welded bar grating finds its place in numerous settings. One of the primary applications is in industrial flooring. Its open structure reduces the accumulation of debris and allows for easy cleaning, which is vital in environments such as food processing plants, chemical facilities, and manufacturing units. Moreover, it can bear heavy loads, making it suitable for transport areas and assembly lines.

welded bar grating

Another key application is in walkways and platforms. The slip-resistant surface provided by the grid pattern increases safety, making it ideal for use in outdoor and industrial environments where conditions may be slippery. Welded bar grating is often used in bridges, stairways, and elevated walkways, providing both support and safety for pedestrians and workers.

Advantages

The advantages of welded bar grating extend beyond its strength and load-bearing capabilities. One significant benefit is its lightweight nature. Compared to solid metal flooring, welded grating is considerably lighter, making it easier to handle and install. This is particularly beneficial in applications where weight restrictions are critical, such as in the construction of portable structures or temporary installations.

Additionally, the open design of weld bar grating promotes airflow and drainage. This feature is especially advantageous in environments that experience heavy rain or snow, as it allows water to flow right through the grating, reducing the chance of flooding or buildup of ice on surfaces. Such properties not only enhance the functionality of the structure but also prolong its lifespan by reducing maintenance needs.

Another major advantage is its versatility. Welded bar grating can be manufactured in various sizes and shapes to fit specific project requirements. It can be customized with different bar spacing and thicknesses, accommodating a wide range of load capacities and usage scenarios.

Conclusion

In conclusion, welded bar grating stands out as a robust and versatile solution for flooring, walkways, and platforms across various industries. Its unique structure, coupled with the advantages of being lightweight, slip-resistant, and customizable, makes it an ideal choice for projects requiring reliable support and safety. As industries continue to evolve and require innovative solutions, welded bar grating remains a fundamental component in the construction and maintenance of modern facilities, ensuring efficient functionality and safety for users.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025