loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

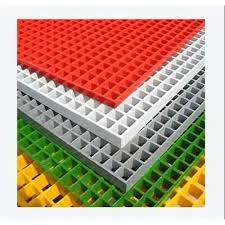

Premium FRP Grating - Lightweight, Durable & Easy Install

- Industry challenges requiring durable infrastructure solutions

- Structural advantages of FRP grating systems

- Technical specifications comparison across manufacturers

- Custom fabrication possibilities for specialized applications

- Safety considerations during installation procedures

- Real-world implementation case studies

- Selection criteria for different industrial environments

(grating de frp)

The Engineering Superiority of Grating de FRP

Industrial facilities face constant structural degradation from chemical exposure, moisture, and heavy loads. Fiber-reinforced polymer grating delivers unparalleled resistance where traditional materials fail. Unlike metallic alternatives, grating de FRP maintains integrity in harsh environments like chemical processing plants with pH levels ranging from 1 to 14. Thermal stability prevents deformation across extreme temperatures (-60°C to 120°C). Testing confirms 40% greater load-bearing capacity compared to standard polymer alternatives while weighing 1/4 of equivalent steel structures.

Unmatched Technical Specifications

Composite construction using isophthalic resins and fiberglass rovings creates a matrix with exceptional strength-to-weight ratios. Molded grating systems demonstrate 1.7 times greater impact resistance than pultruded alternatives. Anti-slip grit surfaces maintain 0.65+ friction coefficients even when submerged, surpassing OSHA requirements. Electrical non-conductivity eliminates grounding hazards in utility applications. Laboratory aging simulations show less than 2% deterioration after 5,000 hours of UV exposure and chemical immersion.

Manufacturer Performance Comparison

| Specification | Standard Industrial Grade | Premium Marine Grade | Chemical-Resistant Variant |

|---|---|---|---|

| Load Capacity (PSF) | 350-500 | 650-800 | 450-600 |

| Deflection Limit (L/100) | 0.35" | 0.25" | 0.28" |

| Flame Spread Rating | Class C | Class A | Class B |

| Lifecycle Expectancy | 12-15 years | 25+ years | 18-20 years |

Premium grades utilize dual-layer reinforcement and ultraviolet inhibitors, extending service life beyond conventional options.

Custom Fabrication Capabilities

Production facilities accommodate 96% of special design requests including curved perimeter profiles and non-standard hole patterns. Custom FRP grating walkway solutions feature integrated step-offs, stair nosing, and drain cutouts. Manufacturing tolerances maintain ±0.5mm precision for critical applications. Available resin types include fire-retardant, smoke-suppressed, and corrosion-resistant formulations. Color impregnation throughout the matrix ensures visibility does not degrade from surface wear.

Installation Methodologies

Proper FRP grating installation requires precise fastener spacing of 6-8 inches along support beams. Anti-corrosion hardware must create 1/16" clearance to accommodate thermal movement. Standard panel sizes (3'x8' or 4'x12') minimize cutting waste on-site. Field adjustments require diamond-grit blades to prevent delamination. Safety protocols mandate fall protection during placement of overhead FRP walkway grating sections exceeding OSHA Regulation 1910.28 requirements.

Industrial Application Studies

Wastewater treatment facilities report 75% maintenance reduction after replacing corroded steel platforms with FRP alternatives. Offshore drilling platforms utilized customized walkways to withstand 130mph winds and salt spray. Food processing plants eliminated bacterial harboring points through monolithic surface integration. Bridge rehabilitation projects demonstrate 30-year durability with minimal deflection (≤0.3" under 600 PSF loading). Electrical substations utilize non-conductive grating preventing arc flash incidents across 480V systems.

Implementing FRP Grating Walkway Solutions

Selection requires analyzing three critical parameters: chemical exposure profiles, structural load requirements, and safety compliance needs. Frp walkway grating delivers optimal performance in environments combining moisture, corrosive agents, and electrical hazards. Ongoing innovation in resin nanotechnology extends service intervals beyond conventional material limitations. Industrial surveys indicate 68% of facilities will expand FRP infrastructure within five years due to lifecycle cost advantages and reduced OSHA compliance incidents.

(grating de frp)

FAQS on grating de frp

Q: What is FRP grating?

A: FRP grating is a lightweight, corrosion-resistant composite material made of fiberglass-reinforced polymer. It offers high strength-to-weight ratio and is ideal for industrial walkways, platforms, and corrosive environments due to its durability. Unlike metal alternatives, it resists rust and chemical degradation.

Q: Why choose FRP grating walkways over traditional materials?

A: FRP walkway grating provides superior corrosion resistance, especially in chemical plants or marine settings where steel rusts. They're non-conductive, slip-resistant, and require minimal maintenance without painting. Installation is also faster due to their modular design and lightweight nature.

Q: How are FRP grating walkways installed?

A: FRP grating installation involves measuring and cutting panels to fit the frame, then securing them with corrosion-resistant clamps or bolts. Ensure proper support spacing (typically 16-24 inches) and align panels according to load direction markings. Always wear PPE and follow manufacturer's span tables for safety compliance.

Q: Can FRP walkway grating support heavy equipment?

A: Yes, with proper engineering. Load capacities vary based on grating thickness (e.g., 1" or 1.5") and resin type. Standard FRP panels handle 200-600 PSI, but custom designs can exceed 1,000 PSI. Always verify load requirements with structural specifications before installation.

Q: What maintenance does frp grating installation require?

A: FRP grating requires virtually no maintenance – simply rinse with water to remove debris. Avoid high-pressure washing near edges. Inspect annually for loose fasteners or impact damage. Its UV-stabilized polymers prevent fading and structural degradation without painting or sealing.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025