loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Februari . 16, 2025 04:49

Back to list

frp structural sections

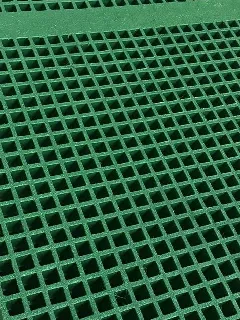

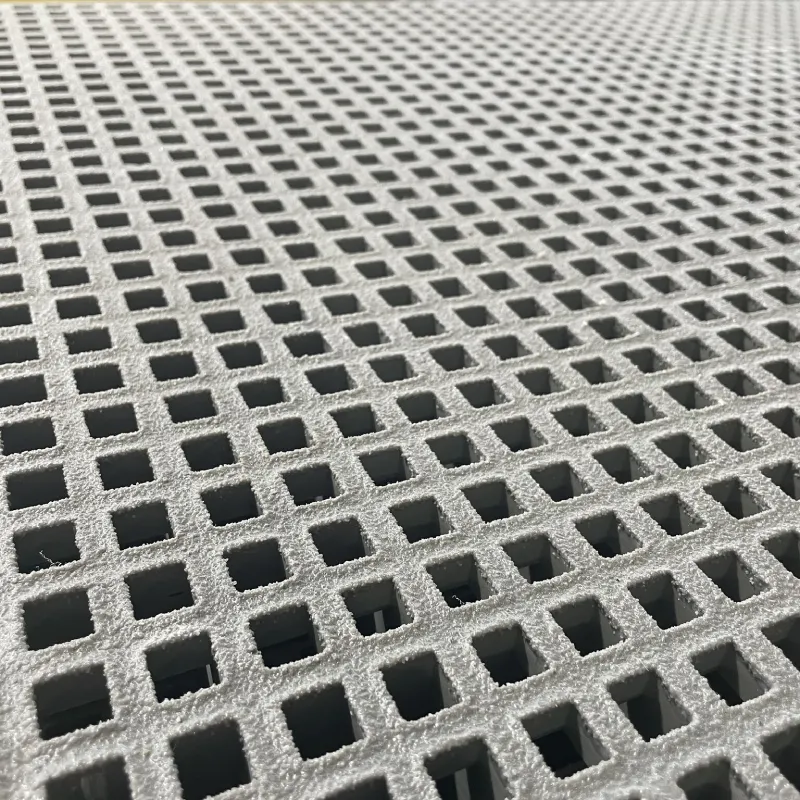

Fiberglass Reinforced Plastic (FRP) structural sections have rapidly gained attention in various industries due to their unique properties and advantages over traditional materials like steel, wood, and aluminum. As companies seek alternatives that promise longevity, resilience, and cost-effectiveness, FRP has emerged as a frontrunner in the race towards modern construction and industrial solutions.

Trustworthiness in FRP products is bolstered by their traceable supply chains and the transparency of their manufacturing processes. Leading manufacturers offer FRP with detailed product data sheets and test reports, curated to ensure users understand the specifications and performance metrics. Ron Summers, a procurement director at a multinational firm, states that the comprehensive warranties offered by top FRP suppliers were a decisive factor in their choice to switch from steel to FRP structural sections. This assurance of quality and reliability fosters trust and encourages widespread adoption. In environmentally-conscious markets, FRP’s sustainable profile plays a significant role. Compared to traditional materials, its production demands lower energy consumption and emits fewer greenhouse gases. Furthermore, the longevity and recyclability of FRP contribute to reducing the environmental impact of infrastructure projects. Construction companies aiming for LEED certification recognize FRP as an optimal choice for earning sustainability credits, aligning with global shifts towards eco-friendly practices. In conclusion, FRP structural sections represent a paradigm shift in materials science and construction methodologies. Bridging practicality with innovative technological advances, FRP stands out for its ease of installation, resilience, longevity, and sustainability. These characteristics provide an unparalleled competitive edge, driving industries forward while setting new benchmarks for excellence and efficiency. As more companies explore and incorporate FRP into their projects, the material’s reputation for reliability, strength, and innovation continues to build, cementing its place as a material of choice for the future.

Trustworthiness in FRP products is bolstered by their traceable supply chains and the transparency of their manufacturing processes. Leading manufacturers offer FRP with detailed product data sheets and test reports, curated to ensure users understand the specifications and performance metrics. Ron Summers, a procurement director at a multinational firm, states that the comprehensive warranties offered by top FRP suppliers were a decisive factor in their choice to switch from steel to FRP structural sections. This assurance of quality and reliability fosters trust and encourages widespread adoption. In environmentally-conscious markets, FRP’s sustainable profile plays a significant role. Compared to traditional materials, its production demands lower energy consumption and emits fewer greenhouse gases. Furthermore, the longevity and recyclability of FRP contribute to reducing the environmental impact of infrastructure projects. Construction companies aiming for LEED certification recognize FRP as an optimal choice for earning sustainability credits, aligning with global shifts towards eco-friendly practices. In conclusion, FRP structural sections represent a paradigm shift in materials science and construction methodologies. Bridging practicality with innovative technological advances, FRP stands out for its ease of installation, resilience, longevity, and sustainability. These characteristics provide an unparalleled competitive edge, driving industries forward while setting new benchmarks for excellence and efficiency. As more companies explore and incorporate FRP into their projects, the material’s reputation for reliability, strength, and innovation continues to build, cementing its place as a material of choice for the future.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025