loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

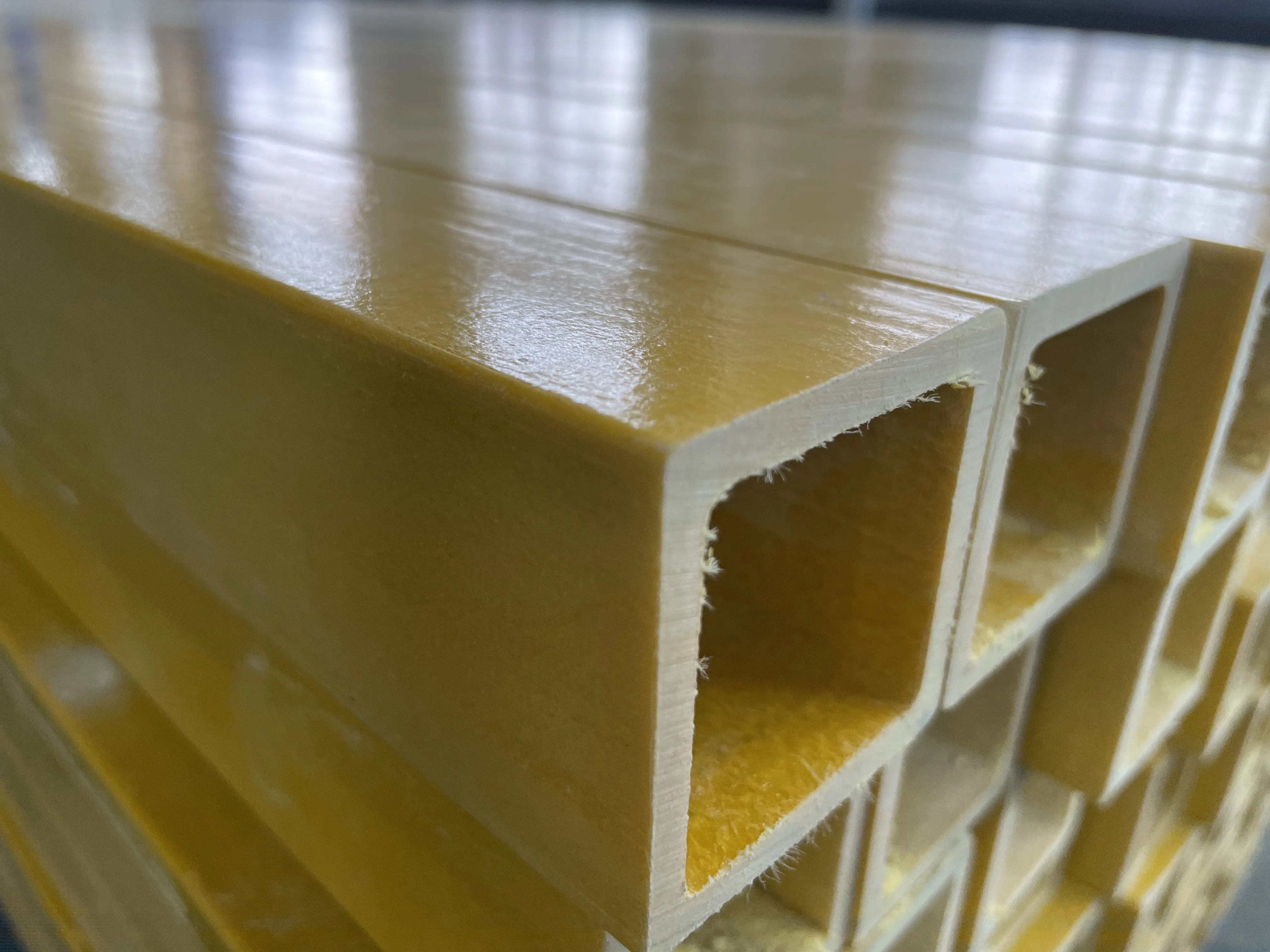

frp square tube

The Versatility of FRP Square Tubes

Fiber Reinforced Polymer (FRP) square tubes have emerged as a revolutionary material in construction and engineering, offering numerous advantages over traditional building materials such as steel and concrete. Comprising a polymer matrix reinforced with fibrous materials, FRP provides exceptional strength-to-weight ratios, corrosion resistance, and design flexibility, making it an ideal choice for a wide range of applications.

The Versatility of FRP Square Tubes

Corrosion resistance is another key advantage of FRP square tubes. In environments where moisture, chemicals, or salt exposure is a concern, traditional metals can corrode over time, leading to significant maintenance costs and shortened material lifespan. In contrast, FRP square tubes do not rust or deteriorate in harsh environments, ensuring longevity and reducing the need for frequent replacements. This makes them an excellent choice for marine, industrial, and infrastructural applications where durability is paramount.

frp square tube

Moreover, FRP tubes can be easily molded into various shapes and sizes, allowing for enhanced design flexibility. Architects and engineers can create complex geometries that would be challenging or impossible with conventional materials. This adaptability is particularly beneficial in industries such as aerospace and automotive, where weight savings and precise design specifications are critical.

Another important aspect of FRP square tubes is their environmental impact. As the construction industry increasingly moves toward sustainable practices, the use of FRP materials aligns with these goals due to their recyclability and energy-efficient production processes. Many manufacturers are committed to using renewable resources in the creation of FRP, reducing the carbon footprint associated with their production.

Additionally, FRP square tubes offer excellent thermal and electrical insulation properties. This feature makes them valuable in applications where temperature control or electrical conductivity is a concern. Their ability to maintain structural integrity under extreme temperatures further enhances their usability across various climates and conditions.

In conclusion, FRP square tubes represent a forward-thinking material solution for modern construction and engineering challenges. Their lightweight, corrosion-resistant, and highly adaptable nature makes them stand out in an industry often dominated by more traditional materials. As we continue to explore innovative materials to meet the demands of contemporary design and environmental sustainability, FRP square tubes are poised to play a pivotal role in shaping the future of infrastructure and architectural development. Whether for bridges, buildings, or specialized industrial applications, the adoption of FRP technology could lead to a new era of efficiency and resilience in construction practices.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025