loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Pressure Vessel Filtering Systems for Enhanced Performance and Durability

Understanding FRP Pressure Vessel Filters A Comprehensive Overview

FRP, or Fiber-Reinforced Plastic, has transformed numerous industries with its unique properties, particularly in the manufacture of pressure vessels and filters. Unlike traditional materials like metal and concrete, FRP offers a lightweight, corrosion-resistant, and cost-effective solution. This article explores the benefits and applications of FRP pressure vessel filters, emphasizing their importance in various sectors.

What are FRP Pressure Vessel Filters?

FRP pressure vessel filters are specialized containers designed to hold or store fluids under pressure while facilitating the filtration process. These filters are commonly used in water treatment, chemical processing, and waste management. The FRP material consists of a polymer matrix reinforced with fibers, typically glass or carbon, which provides strength and resistance to harsh environmental conditions.

Advantages of FRP Pressure Vessel Filters

1. Corrosion Resistance One of the most significant advantages of FRP pressure vessels is their outstanding resistance to corrosive substances. Traditional metal vessels may succumb to rust and degradation over time, especially in chemical applications. In contrast, FRP maintains its integrity even when exposed to aggressive chemicals, thereby extending its service life.

2. Lightweight Design The lightweight nature of FRP makes it easier to transport and install compared to heavier materials such as steel or concrete. This characteristic is particularly advantageous in applications where weight constraints are critical or when installation in elevated locations is required.

3. Cost-Effectiveness While the initial investment for FRP tanks may be higher than for traditional materials, the long-term savings from reduced maintenance costs and longer service life make FRP an economically viable choice. The durability and efficiency of FRP can lead to significant reductions in repair and replacement expenditures.

4. Customizability FRP technology allows for a high degree of customization in terms of shapes, sizes, and configurations. Manufacturers can design pressure vessels tailored to specific applications, optimizing the filtration process to meet unique requirements.

5. Thermal Insulation FRP pressure vessels also exhibit excellent thermal insulation properties. This feature is particularly beneficial in industries where temperature variations can affect the quality of the fluid being filtered.

frp pressure vessel filter

Applications of FRP Pressure Vessel Filters

FRP pressure vessel filters have found extensive applications across various industries due to their versatility and effectiveness. Some key areas include

1. Water Treatment In municipal and industrial water treatment facilities, FRP filters are used to remove impurities, sediments, and contaminants from water. Their excellent corrosion resistance ensures that they can withstand the harsh environments often found in water treatment processes.

2. Chemical Processing Many chemical processes involve aggressive and corrosive substances. FRP pressure vessels are ideal for safely containing and filtering these chemicals, preventing leaks and ensuring the safety of personnel and the environment.

3. Waste Management In waste treatment facilities, FRP pressure vessel filters help to process and filter out hazardous waste, protecting both workers and surrounding ecosystems. Their ability to handle corrosive waste materials makes them invaluable in the waste management sector.

4. Pharmaceuticals The pharmaceutical industry requires high purity and cleanliness standards in all processes. FRP pressure vessel filters meet these requirements while effectively filtering fluids and ensuring that the final products are safe for consumption.

5. Food and Beverage In the food and beverage industry, maintaining hygiene is crucial. FRP filters play a vital role in the filtration of liquids, ensuring that products are free from contaminants while adhering to health and safety regulations.

Conclusion

FRP pressure vessel filters represent a significant advancement in filtration technology, combining lightweight design, corrosion resistance, and cost-effectiveness. Their varied applications across different industries underscore their versatility and utility. As industries continue to seek materials that meet rigorous performance standards while remaining economically viable, FRP pressure vessel filters are poised to play an increasingly important role in the future of fluid filtration and containment. By investing in this innovative technology, businesses can enhance operational efficiency and sustainability, paving the way for advancements in industrial processes.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

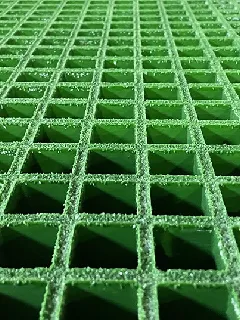

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025