loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp post

Understanding FRP and Its Applications in Modern Engineering

Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. This innovative material has been gaining traction in various engineering fields due to its unique properties, such as high strength-to-weight ratio, corrosion resistance, and flexibility in design. In this article, we will explore the fundamentals of FRP, its advantages, and its expanding applications in modern engineering.

The Composition of FRP

FRP typically consists of two main components the polymer matrix and the reinforcing fibers. The polymer matrix can be made from various types of resins, including thermosetting resins such as epoxy, polyester, and vinyl ester. The reinforcing fibers can be made from materials like glass, carbon, or aramid. Each combination of matrix and fiber offers different mechanical properties, allowing engineers to tailor FRP to specific applications.

Advantages of FRP

1. High Strength-to-Weight Ratio One of the most significant advantages of FRP is its remarkable strength-to-weight ratio. This characteristic makes it an ideal choice for applications where reducing weight is critical, such as in aerospace, automotive, and construction industries.

2. Corrosion Resistance Unlike traditional materials such as steel, FRP does not corrode when exposed to harsh environmental conditions and chemicals. This property extends the lifespan of structures and components made from FRP, reducing maintenance costs and downtime.

3. Versatility in Design FRP can be molded into complex shapes, allowing for innovative designs that would be challenging or impossible with conventional materials. This versatility leads to more aesthetically pleasing designs and optimized structural performance.

4. Electrical and Thermal Insulation FRP offers excellent electrical insulation properties, making it suitable for applications in electrical enclosures and components. Additionally, it exhibits low thermal conductivity, making it an ideal choice for applications requiring thermal insulation.

frp post

Applications of FRP

FRP has a wide range of applications across various industries

1. Construction and Civil Engineering FRP is commonly used in the construction of bridges, buildings, and other structures. Its lightweight nature allows for easier handling and installation. Furthermore, FRP reinforcements are often used in concrete structures to improve their load-bearing capacity and resistance to cracking.

2. Aerospace and Automotive In the aerospace industry, FRP plays a crucial role in reducing the weight of aircraft while maintaining structural integrity. Similarly, in the automotive sector, FRP components are used in body panels, frames, and interiors to enhance fuel efficiency and performance.

3. Marine Applications The marine industry uses FRP for boat hulls, decking, and other components due to its resistance to saltwater and other corrosive environments. This characteristic ensures longevity and reduces the need for frequent repairs.

4. Renewable Energy FRP is widely used in the manufacturing of wind turbine blades. The material's lightweight and high strength enable the construction of longer blades, which can capture more wind and generate more energy.

5. Infrastructure FRP materials are increasingly being used in the rehabilitation of aging infrastructure. For example, FRP plates can be applied to strengthen existing concrete beams and columns without adding significant weight.

Conclusion

Fiber Reinforced Polymer (FRP) is revolutionizing various industries with its exceptional properties and applications. As technology advances and research continues to unlock new possibilities, FRP’s role in modern engineering will only grow. Its unique combination of strength, lightweight characteristics, and resistance to corrosion positions it as a material of choice for both current and future projects. As we look toward innovative solutions for infrastructure, transportation, and energy, FRP stands as a beacon of material science excellence, promising improved performance and sustainability.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

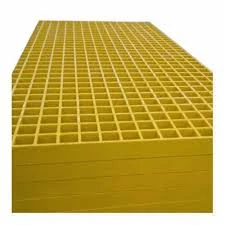

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025