loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Costs and Benefits of Fiberglass Rebar for Construction Projects

The Cost of Fiberglass Rebar A Comprehensive Overview

In the construction industry, materials play a critical role in determining the durability, strength, and cost-effectiveness of a project. One such innovative material that has gained popularity over the years is fiberglass rebar. This article will delve into the cost aspects of fiberglass rebar and its comparison to traditional steel rebar, ultimately shedding light on its value in modern construction.

What is Fiberglass Rebar?

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is made from a combination of fiberglass strands and a polymer resin. This composite material is designed to be an alternative to conventional steel rebar, which has been the standard reinforcement material in concrete structures for decades. The inherent properties of fiberglass rebar include high tensile strength, resistance to corrosion, lightweight, and non-conductivity, making it an appealing option for various applications.

Understanding the Cost of Fiberglass Rebar

The cost of fiberglass rebar can vary significantly based on several factors, including its manufacturer, the grade of fiberglass, and the region in which it is purchased. On average, fiberglass rebar can cost anywhere from $0.70 to $1.50 per linear foot, depending on these variables. When compared to traditional steel rebar, which usually ranges from $0.25 to $0.75 per linear foot, the initial cost of fiberglass rebar might seem higher.

However, the cost should not be the only consideration when selecting materials for a construction project. Factors such as long-term performance, maintenance requirements, and the specific environmental conditions of the project site play vital roles as well.

Advantages of Fiberglass Rebar

1. Corrosion Resistance Unlike steel, fiberglass rebar does not succumb to rust or corrosion when exposed to moisture or aggressive chemicals. This resistance can significantly reduce maintenance costs and extend the lifespan of structures, particularly in coastal areas, chemical plants, or where de-icing salts are used.

fiberglass rebar cost

2. Lightweight Fiberglass rebar is considerably lighter than steel, making transportation and handling easier. This property can reduce labor costs and accelerate the installation process.

3. Enhanced Strength Despite being lighter, fiberglass rebar offers high tensile strength, providing excellent support for concrete structures without compromising their integrity.

4. Non-Conductivity Being a non-metallic material, fiberglass rebar does not conduct electricity, making it a safer option in certain applications, such as in electrical installations or near sensitive equipment.

Long-Term Cost Savings

While the initial investment in fiberglass rebar may be higher, it is essential to consider the long-term savings potential. Projects that implement fiberglass rebar often witness reduced lifecycle costs due to decreased maintenance and repairs. Additionally, structures reinforced with fiberglass rebar can withstand environmental stresses better than those reinforced with steel, leading to fewer issues and extended operational life.

For instance, in a marine environment, the corrosion resistance of fiberglass rebar can eliminate the need for protective coatings or frequent replacements, which can save considerable sums over time. Similarly, in applications such as highways or bridges, lower repair and maintenance schedules can result in better resource allocation and planning for city and governmental budgets.

Conclusion

In summary, while fiberglass rebar may come with a higher upfront cost compared to traditional steel, the benefits it offers—including corrosion resistance, lightweight properties, and long-term durability—can result in significant savings over the lifespan of a project. As environmental concerns and the need for sustainable construction practices grow, materials like fiberglass rebar present an innovative and cost-effective solution in the construction industry. For builders and developers considering their options, it is essential to evaluate both initial costs and long-term implications to make an informed decision that supports both their budget and project goals.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

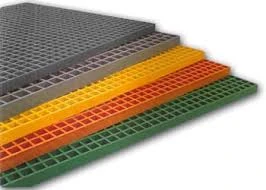

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025