loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Anti-Slip Mini Mesh Grating | GRP & FRP High Strength

Introduction to Advanced mini mesh grating Solutions

In industrial and commercial environments, the selection of appropriate flooring and structural materials is paramount for safety, durability, and operational efficiency. Among the diverse range of grating solutions available, mini mesh grating, particularly in its Fiber Reinforced Polymer (FRP) variant, stands out as a superior choice for demanding applications. Unlike standard FRP gratings, mini mesh grating features a significantly smaller open mesh area, offering enhanced load distribution, improved comfort for foot traffic, and superior heel-proof characteristics. This detailed overview will delve into the technical aspects, advantages, and applications of this critical industrial component, providing B2B decision-makers with comprehensive insights.

The smaller aperture design of mini mesh grating is engineered to meet stringent safety requirements, preventing small objects from falling through and ensuring a more stable walking surface for personnel. Its robust construction, typically utilizing high-performance resins and continuous glass fibers, delivers exceptional corrosion resistance, high strength-to-weight ratio, and non-conductive properties, making it ideal for a multitude of challenging environments where traditional materials often fail.

Industry Trends and Market Dynamics

The global market for FRP grating, including specialized mini mesh grating, is experiencing steady growth driven by increasing demand from infrastructure development, industrial modernization, and a heightened focus on worker safety and environmental compliance. Key trends shaping this market include:

- Sustainable Solutions: A growing preference for materials that offer extended service life, reduced maintenance, and energy efficiency in their production or application. FRP's longevity and minimal maintenance contribute significantly to sustainability goals.

- Enhanced Safety Standards: Stricter safety regulations across industries, particularly in chemical processing, oil & gas, and wastewater treatment, are driving the adoption of non-slip, corrosion-resistant, and non-conductive grating solutions like `grp mini mesh grating`.

- Material Innovation: Ongoing advancements in resin chemistry and fiber reinforcement techniques are leading to FRP gratings with improved fire retardancy, UV stability, and load-bearing capacities.

- Customization: Increasing demand for tailored solutions to meet specific project requirements, including custom panel sizes, colors, and resin formulations for unique chemical exposures or temperature ranges.

The market is projected to continue its upward trajectory, with analysts forecasting a compound annual growth rate (CAGR) of 5-7% for the FRP grating market over the next five years, indicating robust opportunities for high-performance products like `frp mini mesh`.

Manufacturing Process: Precision and Quality Assurance

The production of high-quality `grp mini mesh grating` involves a meticulously controlled process, ensuring product consistency, superior mechanical properties, and extended service life. The primary method for manufacturing FRP grating is the molding process, sometimes complemented by pultrusion for specific profiles.

Detailed Process Flow for Molded FRP Mini Mesh Grating:

- Material Preparation:

- Resin System Selection: Thermosetting resins such as Isophthalic Polyester, Vinyl Ester, Phenolic, or specially formulated fire-retardant resins are chosen based on the intended application's chemical resistance, temperature, and fire rating requirements. Catalysts, inhibitors, UV stabilizers, and pigments are added to the resin mixture.

- Fiberglass Reinforcement: Continuous fiberglass rovings and mats (e.g., woven or chopped strand mats) are prepared. These provide the structural integrity and load-bearing capacity.

- Mold Preparation: Precision-machined molds, typically made from steel or aluminum, are cleaned and coated with a release agent to prevent adhesion and ensure easy demolding. The mold cavities define the intricate `frp mini mesh` structure.

- Laying Up (Impregnation):

- A layer of resin is typically applied to the bottom of the mold.

- Alternating layers of continuous fiberglass rovings and mats are strategically placed within the mold. The rovings run in both load-bearing directions (bi-directional), providing maximum strength.

- The resin mixture is poured or injected to thoroughly impregnate the fiberglass, ensuring complete saturation and minimal voids. This step is critical for composite integrity.

- Curing:

- The filled mold is then subjected to heat, typically in an oven, to initiate the exothermic polymerization reaction. This process, known as curing, transforms the liquid resin into a solid, rigid thermoset plastic, binding the fiberglass reinforcement into a strong, monolithic structure.

- Precise temperature and time control are essential to achieve optimal mechanical properties and prevent defects.

- Demolding and Post-Curing:

- Once cured, the grating panel is carefully demolded.

- Some products may undergo a post-curing cycle to fully cross-link the resin, enhancing chemical resistance and high-temperature performance.

- Finishing and Quality Control:

- Panels are trimmed to standard or custom sizes using specialized cutting equipment, ensuring clean edges.

- A high-quality aggregate grit surface can be applied for enhanced slip resistance, adhering to standards like ASTM F1677.

- Testing Standards: Each batch undergoes rigorous quality control, including visual inspection for defects, dimensional checks, and mechanical testing (e.g., ultimate tensile strength, flexural strength, deflection under load) according to industry standards such as ASTM E84 (flame spread), ASTM D638 (tensile properties), ASTM D790 (flexural properties), and ISO 9001 quality management system certification.

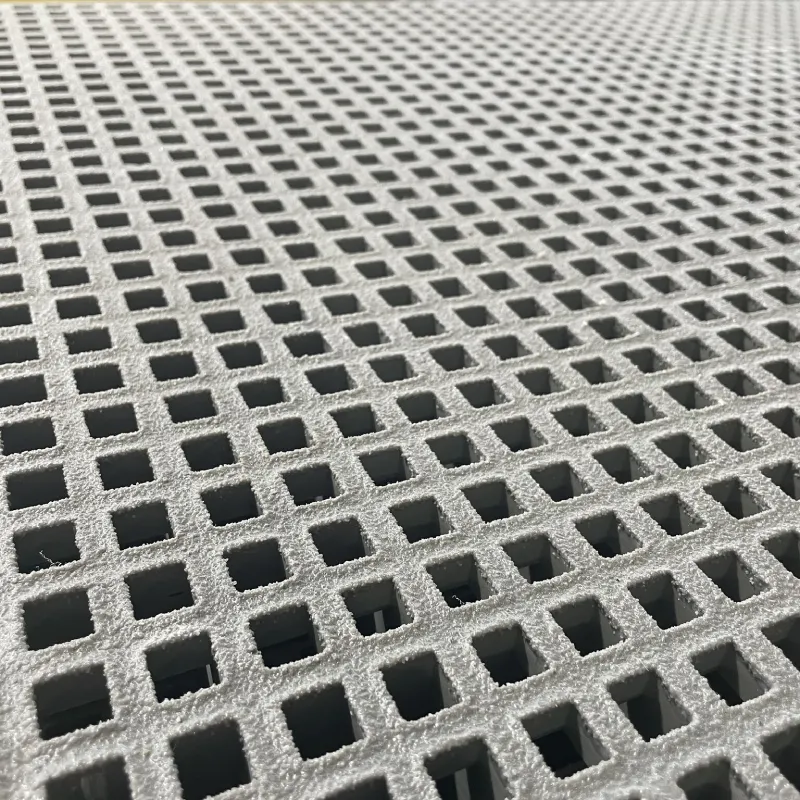

Figure 1: High-strength mini mesh grating for industrial applications.

Target industries benefiting from this manufacturing precision include petrochemical, chemical processing, metallurgy, water supply & drainage, marine, and food & beverage. The inherent advantages, such as exceptional corrosion resistance, non-conductivity, and minimal maintenance, translate directly into energy savings and reduced operational costs over the product's impressive service life, often exceeding 20 years in harsh conditions.

Technical Specifications and Parameters

Understanding the technical specifications of `frp mini mesh` is crucial for proper selection and installation. These parameters dictate the grating's suitability for specific load requirements, environmental conditions, and safety criteria.

Typical Product Specifications for Smaller Open Mesh Area FRP Mini Mesh Grating

| Parameter | Standard Value / Range | Details |

|---|---|---|

| Mesh Size (Center to Center) | Typically 19x19mm, 20x20mm, 25x25mm | Smaller apertures for enhanced foot comfort and prevention of small object fall-through. |

| Panel Thickness / Height | 25mm, 30mm, 38mm (1", 1.25", 1.5") | Determines load capacity and span capabilities. |

| Standard Panel Size | 1220x3660mm (4'x12'), 995x3000mm, etc. | Common dimensions for ease of installation and reduced waste. Custom sizes available. |

| Resin Type | Isophthalic Polyester, Vinyl Ester, Phenolic | Selected based on chemical resistance and temperature requirements. Isophthalic for general purpose, Vinyl Ester for aggressive chemicals, Phenolic for fire resistance. |

| Fiberglass Content | Typically 30-35% by weight | Provides structural integrity and strength. |

| Load Capacity (Uniform Load) | Varies significantly by span and thickness (e.g., 20 kPa at 1m span for 38mm thickness) | Engineered for specific load requirements, consult load tables for exact figures. |

| Weight | ~12-20 kg/m² depending on thickness | Significantly lighter than steel, reducing installation costs and structural support requirements. |

| Slip Resistance | High (e.g., >0.8 coefficient of friction with gritted surface) | Achieved through integral grit top surface, meeting international safety standards. |

| Flame Spread Rating (ASTM E84) | Class 1 (25 or less) for fire-retardant resins | Crucial for applications requiring specific fire safety compliance. |

| UV Resistance | Excellent with UV inhibitors in resin | Prevents degradation and discoloration in outdoor applications. |

These specifications are generalized; actual product performance depends on specific manufacturing and material choices. Always refer to the manufacturer's official data sheets for precise figures relevant to the chosen `frp mini mesh` product.

Technical Advantages of FRP Mini Mesh Grating

The inherent properties of FRP, combined with the specialized `grp mini mesh grating` design, offer a multitude of technical advantages over traditional materials such as steel, aluminum, or standard open mesh FRP.

- Superior Corrosion Resistance: FRP mini mesh is impervious to a wide range of corrosive chemicals, acids, and alkalis, making it ideal for chemical plants, wastewater treatment facilities, and marine environments where steel would rapidly degrade. This directly translates to an extended service life and reduced replacement costs.

- Enhanced Safety (Heel-Proof & Anti-Slip): The smaller mesh openings prevent small tools, nuts, bolts, and other debris from falling through, protecting equipment below and reducing potential hazards. This `mini mesh grating` also ensures that high-heeled shoes cannot penetrate the surface, making it suitable for areas with mixed pedestrian traffic. A factory-applied grit surface provides exceptional slip resistance, even in wet or oily conditions.

- High Strength-to-Weight Ratio: Despite being significantly lighter (often 1/4 the weight of steel grating), `frp mini mesh` offers comparable or superior load-bearing capacity. This reduces the need for heavy lifting equipment during installation and minimizes structural support requirements, leading to significant cost savings in construction.

- Non-Conductive and Non-Magnetic: FRP is electrically and thermally non-conductive, offering a safe solution in areas with electrical hazards or where electromagnetic interference must be avoided (e.g., data centers, electrical substations, MRI rooms).

- Low Maintenance and Long Service Life: FRP does not rust, pit, or require painting, significantly reducing ongoing maintenance costs. Its resistance to environmental degradation ensures a long service life, often exceeding 20 years, even in harsh conditions.

- Impact Resistance: FRP has excellent elastic properties, allowing it to absorb impact without permanent deformation, unlike metal gratings which can bend or dent.

- Ergonomic Comfort: The smaller mesh size provides a more comfortable walking surface for personnel, reducing foot fatigue over long shifts, particularly beneficial in industrial facilities.

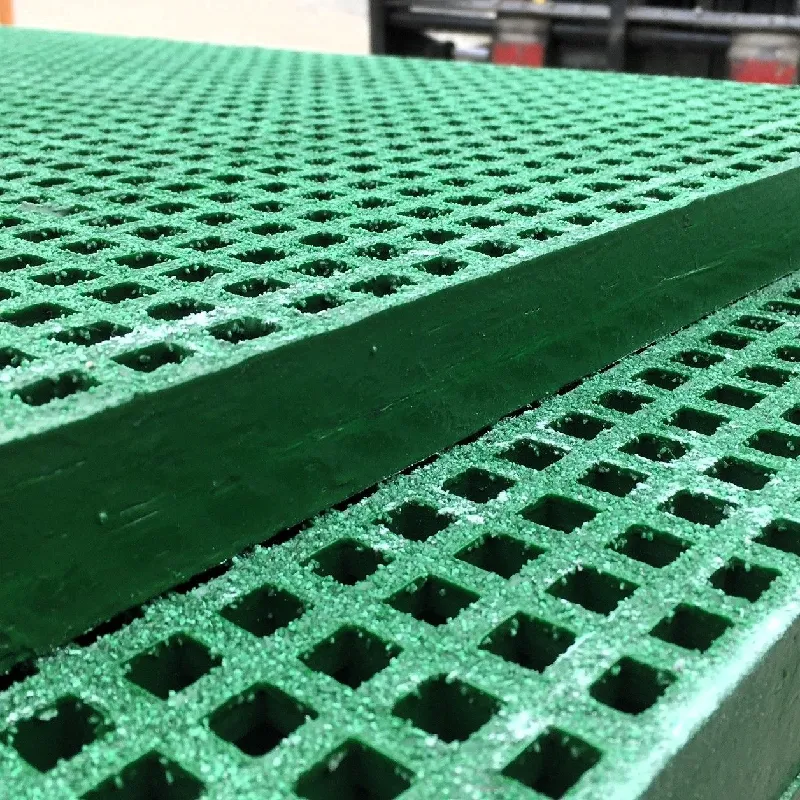

Figure 2: Mini mesh grating installed in a corrosive environment, demonstrating its resilience.

Application Scenarios Across Key Industries

The unique combination of properties offered by `grp mini mesh grating` makes it an invaluable material across a diverse range of demanding industrial and commercial applications:

- Chemical Processing Plants: Platforms, walkways, trench covers, and sumps where exposure to highly corrosive acids, alkalis, and solvents necessitates superior chemical resistance.

- Oil & Gas (Onshore and Offshore): Walkways on drilling rigs, platforms, and refineries, especially where non-sparking properties are crucial and resistance to hydrocarbons and saltwater is paramount. The smaller mesh also prevents dropped tools from falling into machinery.

- Wastewater Treatment Facilities: Screens, aeration basins, clarifiers, and filter media supports, benefiting from outstanding corrosion resistance and minimal maintenance in continuously wet and chemically aggressive environments.

- Food & Beverage Processing: Flooring, catwalks, and drainage covers in wash-down areas, where hygiene, slip resistance, and resistance to cleaning agents are critical. The smaller mesh minimizes trapping of food particles.

- Marine and Shipbuilding: Decks, gangways, and access platforms on vessels and docks, offering excellent resistance to saltwater, UV degradation, and heavy foot traffic.

- Electrical Utilities and Substations: Non-conductive platforms and walkways around high-voltage equipment, enhancing worker safety against electrical hazards.

- Architectural and Commercial: Aesthetic appeal combined with safety features for public access areas, building entrances, and decorative screens where heel-proof characteristics are desired.

Vendor Comparison: Choosing the Right Partner

Selecting a reliable supplier for `frp mini mesh` is as critical as the product itself. A comprehensive vendor comparison should evaluate several key aspects beyond just unit price.

Key Factors for Vendor Evaluation:

- Product Quality & Certifications: Look for manufacturers with ISO 9001 certification for quality management, and products meeting international standards like ASTM, ANSI, or specific regional codes. Verify material test data and fire ratings.

- Technical Expertise & Support: A strong vendor provides engineering support, design assistance, and technical data. Their ability to understand your specific application and recommend the optimal `mini mesh grating` solution is paramount.

- Customization Capabilities: Assess their capacity to provide custom panel sizes, specific resin formulations, colors, and fabrication services (e.g., cutting, notching, shaping).

- Lead Times & Fulfillment: Evaluate their production capacity and logistics to ensure timely delivery, especially for large or critical projects.

- Reputation & Experience: A vendor's track record, years in service, and client testimonials or case studies provide insights into their reliability and product performance. Look for partnerships with reputable clients.

- Warranty & After-Sales Service: Understand the warranty terms for `grp mini mesh grating` products and the level of post-purchase support offered.

FRP Mini Mesh Grating vs. Other Industrial Gratings: A Comparative Overview

| Feature | FRP Mini Mesh Grating | Standard FRP Grating | Steel Grating | Aluminum Grating |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (resin dependent) | Excellent (resin dependent) | Poor (requires coating/galvanizing) | Good (passivation layer) |

| Weight | Very Low | Low | High | Moderate |

| Heel-Proof / Small Object Retention | Excellent | Fair (standard openings) | Poor (large openings) | Fair (standard openings) |

| Slip Resistance (Gritted) | Excellent | Excellent | Good (serrated options) | Fair (knurled options) |

| Electrical Conductivity | Non-Conductive | Non-Conductive | Conductive | Conductive |

| Maintenance Cost | Very Low | Very Low | High (painting, rust removal) | Low-Moderate |

| Fire Resistance (Phenolic) | Excellent (Class 1) | Good (Class 1 for fire-retardant resins) | Excellent | Good (non-combustible) |

Customized Solutions for Specific Project Needs

Recognizing that no two industrial projects are identical, leading manufacturers offer extensive customization options for `mini mesh grating` to precisely match unique operational and environmental requirements. This includes:

- Resin Formulations: Tailoring resin types (e.g., Isophthalic, Vinyl Ester, Phenolic) with specific additives for enhanced resistance to particular chemicals, higher temperature tolerance, or superior fire retardancy (e.g., meeting UL 94 V-0).

- Panel Sizes & Shapes: Custom cutting and fabrication to non-standard dimensions, intricate shapes, or patterns to fit around pipes, machinery, or structural elements, minimizing waste and installation time.

- Color Matching: Production in various custom colors to align with corporate branding, safety coding, or architectural aesthetics, ensuring consistency and visual appeal.

- Surface Finishes: Options for specific grit types (fine, medium, coarse), concave surfaces, or smooth finishes depending on the required slip resistance and ease of cleaning.

- Conductivity Modification: While inherently non-conductive, some applications may require static dissipative properties, which can be achieved through specialized resin additives.

Engaging with a manufacturer that possesses deep engineering capabilities allows for the development of bespoke `grp mini mesh grating` solutions that deliver optimal performance and cost-effectiveness for the entire project lifecycle.

Application Case Studies & Customer Feedback

Real-world applications vividly demonstrate the tangible benefits of integrating `frp mini mesh` into critical infrastructure.

Case Study 1: Offshore Oil Platform Decking

- Challenge: An offshore oil platform required a lightweight, highly corrosion-resistant, and non-slip decking material for maintenance walkways and work areas. Traditional steel grating was prone to rust in the saltwater environment, heavy to install, and presented a spark hazard.

- Solution: Installation of 38mm thick Vinyl Ester `grp mini mesh grating` with a coarse grit surface. The smaller mesh provided enhanced safety, preventing dropped tools from falling into the sea or machinery below.

- Results: Reduced installation time and cost due to lightweight panels. Zero corrosion reported after 5 years, significantly reducing maintenance. Enhanced worker safety due to superior slip resistance and non-conductive properties. "The `mini mesh grating` has truly transformed our deck safety and dramatically cut down on replacement and maintenance costs," stated the platform manager.

Figure 3: Durable and safe mini mesh grating in an industrial setting.

Case Study 2: Chemical Plant Walkways

- Challenge: A facility producing strong acids and bases needed a durable flooring solution for elevated walkways and process areas. Previous metallic grating corroded quickly and posed a continuous slip hazard when exposed to chemical spills.

- Solution: Implementation of Isophthalic Polyester `mini mesh grating` with a fine grit surface for walkways and Phenolic `frp mini mesh` for areas requiring high fire resistance.

- Results: Complete elimination of corrosion-related failures and significantly improved slip resistance, even in the presence of various chemicals. The heel-proof nature of the grating provided an added layer of safety for all personnel. Maintenance staff reported dramatically reduced cleaning times due to the easy-to-clean surface.

Trust & Support: FAQ, Lead Time, Warranty, and Customer Service

Building long-term partnerships requires transparency and robust support. Here's what you can expect:

Frequently Asked Questions (FAQ)

- Q: Is FRP mini mesh grating suitable for heavy vehicle traffic?

- A: While extremely strong, FRP mini mesh is primarily designed for pedestrian and light vehicle traffic (e.g., forklifts). For heavy vehicular loads, specific high-load pultruded FRP profiles or reinforced molded gratings would be recommended. Always consult load tables for specific applications.

- Q: How do I install FRP mini mesh grating?

- A: FRP grating can be easily cut using standard power tools with diamond-tip blades. Panels are secured to support structures using specially designed FRP or stainless steel clips and fasteners. Detailed installation guides are provided with every order.

- Q: Can FRP mini mesh be used outdoors in direct sunlight?

- A: Yes, high-quality `grp mini mesh grating` contains UV inhibitors within the resin system to prevent degradation and discoloration from prolonged sun exposure, ensuring longevity in outdoor environments.

- Q: What is the typical cleaning procedure for FRP mini mesh?

- A: FRP grating requires minimal cleaning. For general maintenance, a simple wash-down with water and a mild detergent is usually sufficient. For stubborn contaminants, consult our technical support for specific recommendations based on the chemical exposure.

Lead Time & Fulfillment

Standard `frp mini mesh` panels typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. Customized orders or large projects may require 4-8 weeks. We maintain robust inventory levels of popular configurations to expedite delivery for urgent requirements. Our logistics team works diligently to ensure efficient and secure global shipping.

Warranty Commitments

We stand by the quality of our products. All `mini mesh grating` products come with a standard 5-year limited warranty against manufacturing defects and material failures under normal use and service conditions. Extended warranty options may be available for specific projects or high-wear applications, demonstrating our confidence in product durability and performance.

Dedicated Customer Support

Our team of technical experts and customer service professionals is available to provide comprehensive support from initial consultation and design to post-installation queries. We offer:

- Detailed product data sheets and chemical resistance guides.

- CAD drawings and engineering support for complex installations.

- Installation best practices and troubleshooting assistance.

- Prompt response to inquiries and efficient order processing.

We are committed to ensuring our clients achieve optimal project outcomes with our high-performance `grp mini mesh grating` solutions.

Conclusion

The adoption of mini mesh grating represents a strategic investment for industries prioritizing safety, longevity, and operational efficiency in challenging environments. Its superior technical attributes, including exceptional corrosion resistance, high strength-to-weight ratio, non-conductivity, and enhanced heel-proof safety features, position it as an indispensable solution where traditional materials fall short. By understanding its detailed manufacturing process, comprehensive technical specifications, diverse application scenarios, and the rigorous quality standards applied, B2B decision-makers can confidently specify and procure these advanced `frp mini mesh` solutions. Partnering with an experienced and reputable manufacturer further ensures access to tailored solutions, robust support, and products that deliver enduring value and performance.

References

- ASTM International. (n.d.). ASTM D790 - Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.

- ASTM International. (n.d.). ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials.

- ISO (International Organization for Standardization). (n.d.). ISO 9001 - Quality management systems — Requirements.

- Fiberglass Grating Manufacturers Council (FGMC) of the American Composites Manufacturers Association (ACMA). (n.d.). Design Guide for Fiber Reinforced Polymer (FRP) Grating.

- MarketsandMarkets. (2023). Fiber Reinforced Polymer (FRP) Grating Market - Global Forecast to 2028.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025