loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

feb . 04, 2025 03:25

Back to list

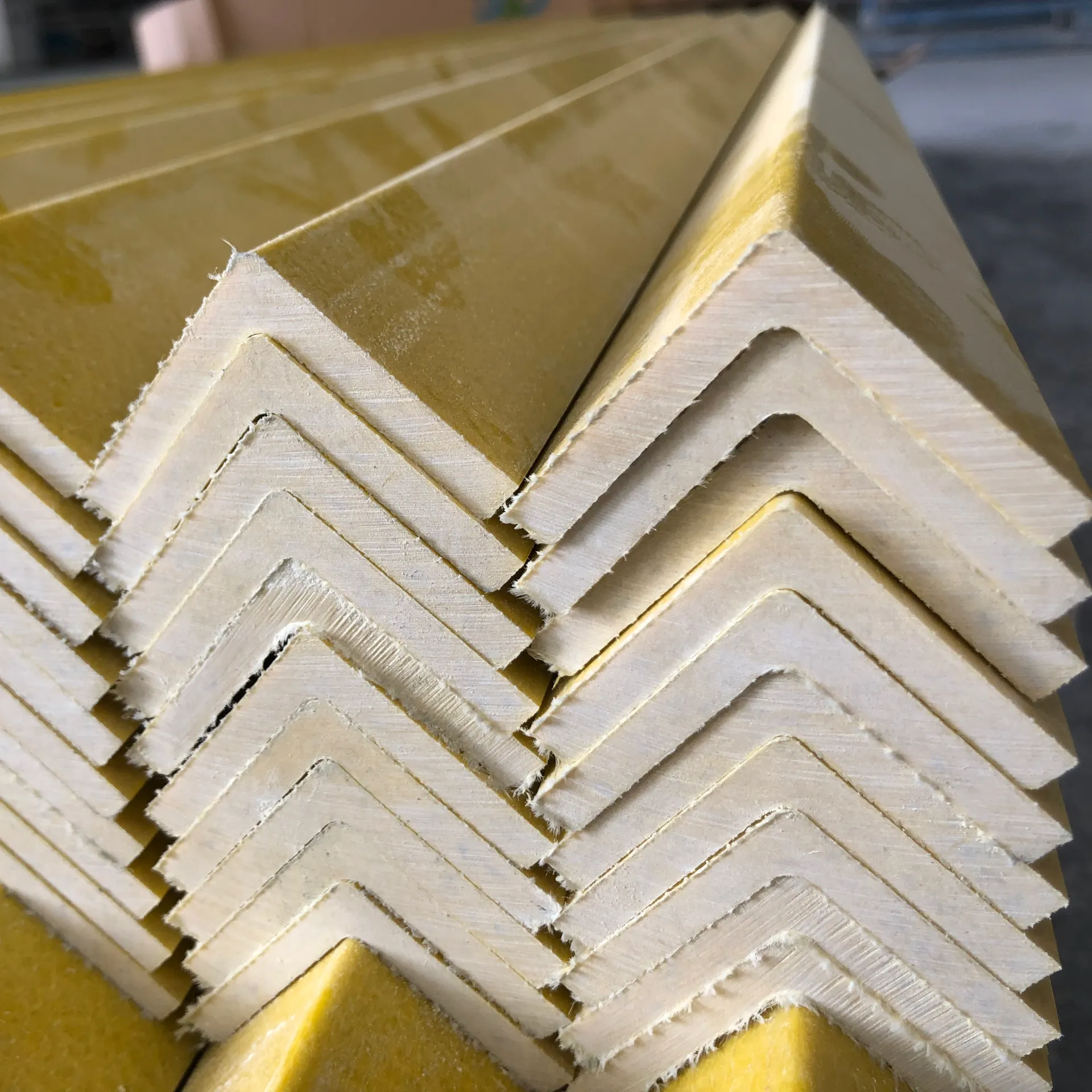

frp micro mesh grating

Mesh gratings, a vital component in various industrial applications, offer a blend of safety, versatility, and durability. Crafted meticulously, these gratings stand as a testament to the advancement in fabrication technology. Their demand continues to rise thanks to their cost-effectiveness and longevity, making them a beloved choice for industries spanning construction to metallurgy.

Trustworthiness is further highlighted through case studies of long-term installations. Many large-scale facilities that have integrated mesh gratings report minimal maintenance requirements over decades of use, underscoring their durability. The prefabricated nature of these gratings allows for seamless installation, often reducing labor costs and installation time. Testimonials from industry professionals frequently note the ease of customization, allowing mesh gratings to meet unique spatial or functional demands without compromising structural soundness. Furthermore, environmentally conscious companies often choose mesh gratings due to their sustainable profiles. The materials used can usually be recycled, aligning with green building practices and reducing environmental footprints. This ecological consideration adds another layer of trust, as businesses increasingly prioritize sustainability in their operations. Mesh gratings continue to evolve with technological advances, ensuring they meet modern industrial needs. Innovative designs and material improvements continuously enhance their capabilities, offering solutions that are both practical and economically sound. As industries grow, so does the application of mesh gratings, proving their indispensable role across various sectors. In conclusion, mesh gratings embody the quintessence of experience, expertise, authority, and trustworthiness. Their continued use and development affirm their place as a staple in industrial solutions, ensuring safety and efficiency for years to come.

Trustworthiness is further highlighted through case studies of long-term installations. Many large-scale facilities that have integrated mesh gratings report minimal maintenance requirements over decades of use, underscoring their durability. The prefabricated nature of these gratings allows for seamless installation, often reducing labor costs and installation time. Testimonials from industry professionals frequently note the ease of customization, allowing mesh gratings to meet unique spatial or functional demands without compromising structural soundness. Furthermore, environmentally conscious companies often choose mesh gratings due to their sustainable profiles. The materials used can usually be recycled, aligning with green building practices and reducing environmental footprints. This ecological consideration adds another layer of trust, as businesses increasingly prioritize sustainability in their operations. Mesh gratings continue to evolve with technological advances, ensuring they meet modern industrial needs. Innovative designs and material improvements continuously enhance their capabilities, offering solutions that are both practical and economically sound. As industries grow, so does the application of mesh gratings, proving their indispensable role across various sectors. In conclusion, mesh gratings embody the quintessence of experience, expertise, authority, and trustworthiness. Their continued use and development affirm their place as a staple in industrial solutions, ensuring safety and efficiency for years to come.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025