loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Leading FRP Grating Suppliers - Durable, Non-Slip, Custom

Choosing FRP Grating Suppliers: Insider Notes from the Shop Floor

If you’re scanning the market for [frp grating suppliers], here’s the short take: the best partners balance materials science with gritty, real-world reliability. In procurement calls, I still hear the same themes—corrosion resistance, slip safety, and lead times. Actually, those last two can make or break a project schedule.

What’s trending in FRP grating

Demand is shifting toward vinyl ester systems for chemical duty, finer anti-slip surfaces for public spaces, and rectangular mesh for higher open area. Urban infrastructure and aquaculture—surprisingly—are two fast adopters. Many customers say they want “metal performance without the corrosion tax,” and that’s basically the pitch.

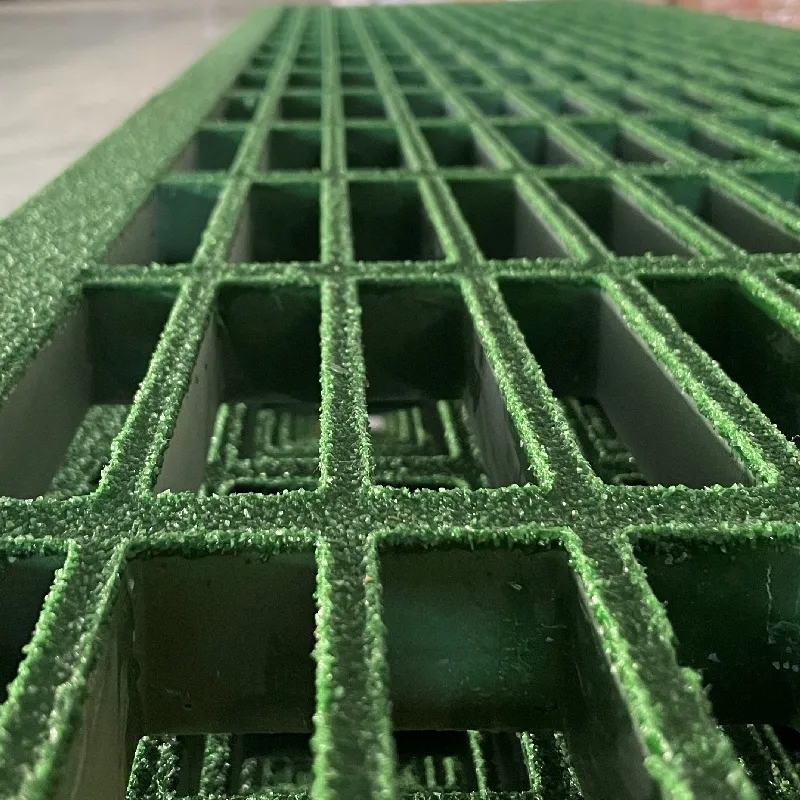

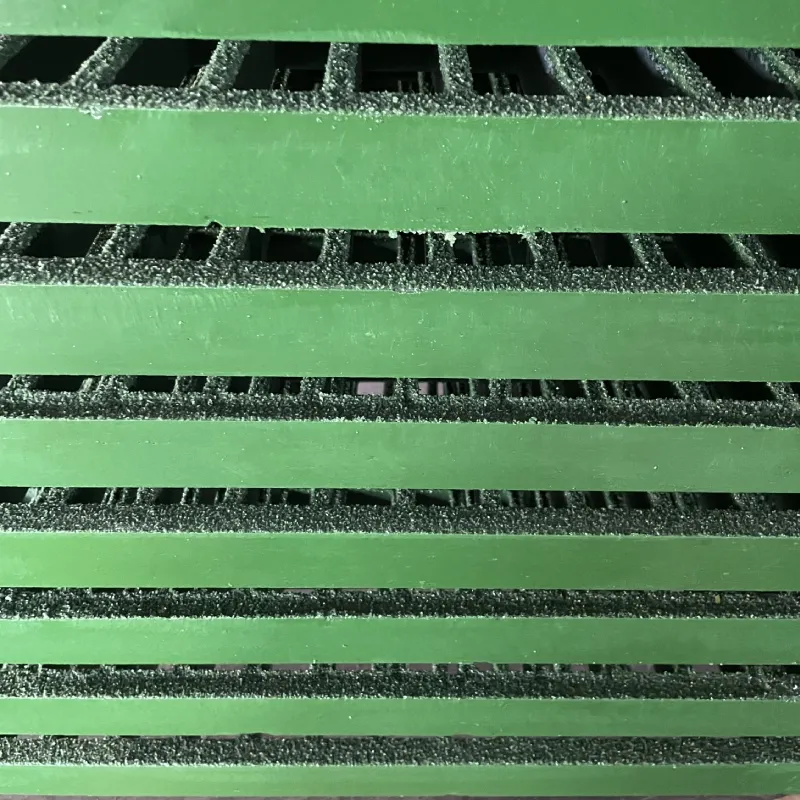

Product spotlight: Moulded Fiberglass Rectangular Mesh Grating

From a manufacturing standpoint, moulded grating means glass rovings and mat are placed in a heated mould, resin-rich and consolidated, then cured, demoulded, trimmed, and tested. Materials typically include E-glass reinforcement, resin (isophthalic or vinyl ester for stronger chemical resistance), pigments, UV inhibitors, and grit for slip resistance. Service life? In benign environments ≈25–30 years; in aggressive chemical or marine exposure, it varies with resin, thickness, and maintenance.

Typical specifications (field-proven, lab-verified)

| Property | Typical value | Notes |

|---|---|---|

| Panel thickness | 25–38 mm | Load/span per ASTM D790, real-world use may vary |

| Mesh opening (rectangular) | ≈ 19×38 mm | Higher open area vs. square mesh |

| Open area | ≈ 60–70% | Better drainage/light transmittance |

| Flexural strength | 200–350 MPa | ASTM D790 |

| Flame spread index | ≤ 25 (with FR system) | ASTM E84 |

| Resin options | Orthophthalic / Isophthalic / Vinyl ester | Pick by chemical exposure |

Where it shines: marine platforms, aquaculture walkways, farming floors, wastewater plants, mineral processing, public access ways, even floor-mounted guarding. Anti-slip grit keeps shoes honest; the dielectric nature helps around electrics.

Comparing [frp grating suppliers] (quick snapshot)

| Supplier | Lead time | Certs / Standards | MOQ | Notes |

|---|---|---|---|---|

| ZJ Composites (Hebei, China) | 2–4 weeks (typ.) | ASTM D790/E84; ISO 9001 | Flexible | Strong on custom colors/surfaces |

| Regional Distributor B | Stock for common sizes | ASTM selection varies | Per SKU | Fast swaps, less customization |

| OEM Exporter C | 4–6 weeks | ISO-based QA | Higher | Competitive on large volumes |

Customization that matters

Specify resin family, panel thickness, mesh opening, color (safety yellow/grey/green), UV package, grit size, and edge banding. Testing per ASTM D790 (flexural) and ASTM D635 (rate of burning) is standard fare; ask for reports and, if it’s a public site, an E84 summary.

Mini case notes (real-world)

- Marine ferry pier: rectangular mesh improved drainage; crew said “boots feel planted” after rain.

- Aquaculture farm: switch from steel to FRP cut slip incidents; algae wash-off is faster, according to site maintenance.

- Mineral processing access: vinyl ester panels survived acid mist; inspection after 18 months showed minimal degradation.

Origin for the highlighted product: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China. If you’re shortlisting [frp grating suppliers], check not just price but test data, resin pedigree, and coating/grit options. To be honest, those details are what keep facilities safer and downtime low.

Authoritative references

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025