loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Water Storage Solutions that A Comprehensive Guide to SMC Panel Technology

In the evolving landscape of water storage solutions, SMC panel water tanks have emerged as a revolutionary technology that combines superior performance with practical installation advantages. These innovative storage systems represent a significant advancement over traditional materials, offering exceptional durability and water quality preservation. Understanding the detailed SMC panel tank specifications is crucial for engineers and project managers to ensure proper application and long-term reliability. For comprehensive budgeting and procurement planning, analyzing the SMC panel water tanks price factors provides valuable insights into the total cost of ownership. The modular design of each SMC panel water tank unit enables flexible capacity planning and straightforward installation, making these systems suitable for diverse applications from commercial buildings to industrial facilities. This comprehensive guide explores the technical aspects, benefits, and economic considerations of SMC panel water storage technology.

The Versatility and Advantages of Smc Panel Water Tanks

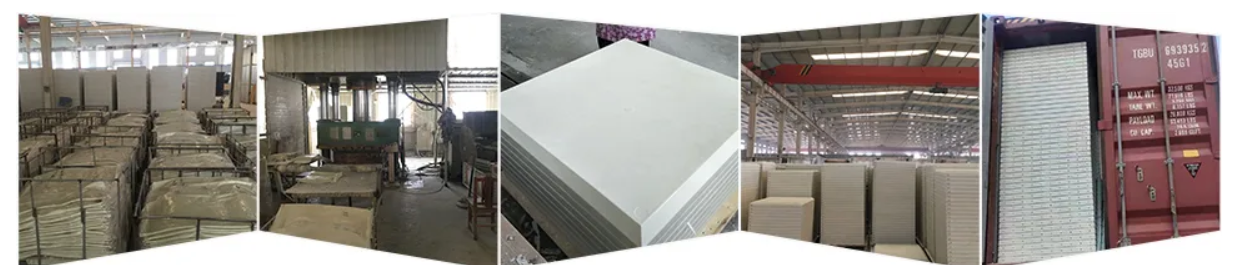

Our smc panel water tanks are assembled from SMC (Sheet Molding Compound) panels—produced via hydraulic press molding—and paired with internal/external accessories and sealants, making them adaptable to diverse storage needs.

Key Benefits of ZJ Composites’ smc panel water tanks:

- Superior Sanitation: The opaque SMC panels block external light, preventing bacteria and germ growth. Unlike concrete tanks with hard-to-clean internal structures, large SMC panels eliminate hidden corners, enabling long-term sanitary use—ideal for potable water, reverse-osmosis water, and food-processing water storage.

- Corrosion Resistance: Both internal components (Storage Tank System with PE coating) and external parts (melt zinc-plated accessories) resist rust and chemical erosion, making smc panel water tankssuitable for fresh/saltwater, septic sewage, and even chemical substance storage.

- Easy Installation: Panels are assembled on-site with standard tools and bolt fasteners—no heavy machinery required. This reduces installation time by 50% compared to prefabricated steel tanks, aligning with ZJ Composites’ focus on convenient, labor-saving solutions.

- Flexible Capacity Design: Available in L-shape, U-shape, and square-shape configurations, we can design tanks from 1,000L to 100,000L to fit irregular spaces (e.g., narrow industrial corners or residential yards).

ZJ Composites’ smc panel water tanks are widely used in agricultural irrigation, fire reserve storage, and industrial process tanks, meeting the diverse needs of global customers.

Understanding Smc Panel Tank Specifications for Optimal Selection

Smc panel tank specifications are tailored to ensure structural stability, hygiene, and compatibility with different applications. Detailed specs help customers select the right tank for their specific needs.

Core smc panel tank specifications from ZJ Composites:

- Panel Material: SMC sheets (fiberglass-reinforced thermosetting plastic) with high strength-to-weight ratio—each panel has a thickness of 5–10mm, ensuring load-bearing capacity while keeping the tank lightweight.

- Sealing Technology: Uses internationally patented special sealants to guarantee 100% water tightness, preventing leaks even in high-pressure or temperature-fluctuating environments (-40℃ to 80℃).

- Accessories: Standard components include structure supports (for stability), liquid level indicators (for water volume monitoring), exterior/interior ladders (for maintenance), and flange connections (for easy piping integration). Custom accessories (e.g., reinforcement plates for heavy loads) are available upon request.

- Hygiene Standards: Complies with global sanitary regulations (e.g., NSF/ANSI for drinking water), with non-toxic, non-porous panel surfaces that avoid water contamination.

The table below summarizes key smc panel tank specifications for common applications:

|

Application |

Panel Thickness |

Recommended Capacity |

Key Accessories |

|

Potable Water Storage |

6mm |

5,000–20,000L |

Liquid level indicator, manhole |

|

Agricultural Irrigation |

5mm |

20,000–50,000L |

Large-diameter drain outlet |

|

Fire Reserve Storage |

8mm |

30,000–100,000L |

High-pressure flange |

|

Industrial Process Tanks |

10mm |

10,000–30,000L |

Reinforcement plates, corrosion-resistant sealant |

The Transparency of Smc Panel Water Tanks Price

While smc panel water tanks price varies by configuration, ZJ Composites maintains transparency to help customers balance quality and budget, ensuring long-term value for investment.

Factors Influencing smc panel water tanks price:

- Panel Quantity & Size: Larger tanks (e.g., 50,000L) require more panels, increasing costs—basic 1,000L tanks start at \(800, while 100,000L industrial tanks range from \)15,000–$25,000. Bulk orders (5+ tanks) qualify for 10–15% discounts.

- Customization: Special requirements (e.g., corrosion-resistant panels for chemical storage, insulated layers for hot water tanks) add 5–20% to smc panel water tanks pricebut extend service life and functionality.

- Accessories: Optional accessories like automatic level sensors or anti-algae coatings increase costs slightly but reduce maintenance efforts—aligning with ZJ Composites’ customer service tenet of “providing optimal solutions.”

Compared to traditional steel tanks (which require \(300–\)500 annual maintenance), smc panel water tanks have minimal upkeep costs, making their total 15-year lifecycle cost 40% lower than steel alternatives. This aligns with ZJ Composites’ ultimate purpose of achieving a win-win situation with customers.

The Durability of Single-Unit Smc Panel Water Tank

A single smc panel water tank (designed for small-to-medium storage needs) offers the same hygiene and durability as large modular tanks, making it ideal for residential, small commercial, or temporary projects.

Features of Our smc panel water tank (Single-Unit):

- Compact Design: Capacities range from 1,000L to 10,000L, with a space-saving square or cylindrical shape that fits in backyards, utility rooms, or small workshops.

- Semi-Permanent Lifespan: The melt zinc-plated external accessories and corrosion-resistant internal structure ensure a service life of 20+ years—no repainting or rust repairs needed, unlike steel tanks.

- Easy Maintenance: The smooth panel surfaces and accessible manholes simplify cleaning (only annual rinsing required), reducing labor costs for homeowners or small businesses.

ZJ Composites’ smc panel water tank is a cost-effective choice for rainwater harvesting, well water storage, or small-scale irrigation, delivering the same quality as larger modular systems.

FAQ About ZJ Composites’ SMC Panel Water Tanks

Can you customize the shape of an smc panel water tank?

Yes, ZJ Composites offers full shape customization for smc panel water tank. We can design L-shaped, U-shaped, or rectangular tanks to fit tight spaces (e.g., between building walls or under stairs). Our engineering team uses 3D modeling to ensure the customized shape maintains structural stability, and we provide a detailed assembly plan before production—backed by our strong technical support.

What maintenance is required for smc panel water tanks?

Smc panel water tanks require minimal maintenance: 1) Clean the internal panels annually with a mild, non-toxic detergent to remove sediment; 2) Inspect sealants and accessories every 6 months (replace cracked gaskets or rusted bolts); 3) Check the liquid level indicator for accuracy. ZJ Composites provides a maintenance guide, and our team offers lifetime technical support for troubleshooting—ensuring the tank remains sanitary and leak-free.

Are smc panel water tanks suitable for hot water storage?

Absolutely. We offer smc panel water tanks with insulated SMC panels (filled with polyurethane foam) for hot water storage, maintaining water temperature (up to 80℃) with minimal heat loss. These tanks are ideal for solar water heating systems, hotels, or industrial facilities requiring hot process water, and they comply with thermal insulation standards to reduce energy costs.

How long does it take to deliver an smc panel water tank?

Delivery time for smc panel water tank depends on size and customization: Standard small tanks (1,000–5,000L) are produced in 7–10 business days, while large customized tanks (50,000L+) take 15–20 business days. International shipping (via ZJ Composites’ global logistics network) takes 10–30 business days, and we provide tracking information to ensure on-time delivery.

Do you provide installation support for smc panel water tanks?

Yes. For standard smc panel water tanks, we provide a detailed on-site assembly manual with step-by-step instructions. For large or complex installations (e.g., industrial 100,000L tanks), we can send engineers for on-site guidance (relevant costs borne by the customer). Our team also offers post-installation leak testing to ensure the tank meets quality standards—upholding ZJ Composites’ commitment to strict quality and thoughtful service.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025