loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

If you’re weighing the never-ending steel maintenance cycle versus modern composites, you’re not alone. Across marine, wastewater, and chemical plants, engineers are swapping heavy metal grating for FRP—largely because total life-cycle costs are finally getting the attention they deserve. To be honest, once you run the math, the shift seems obvious.

What’s different about Holiday Special Offers GRP FRP Gratings Fiberglass Grates?

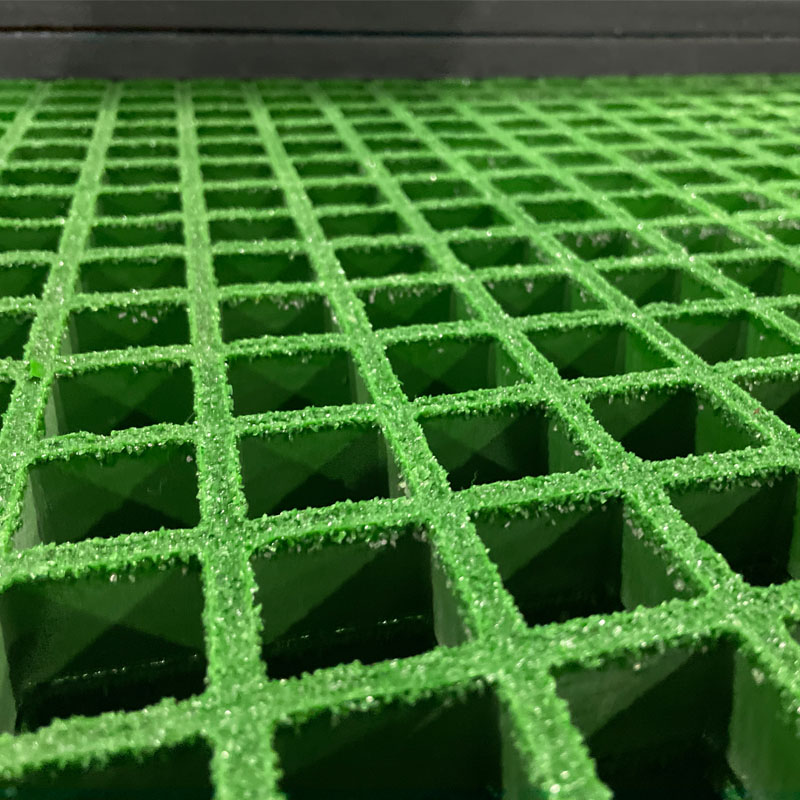

From ZJ Composites (Hebei, China), these molded and pultruded FRP panels—standard, mini, and micro-mesh—deliver light weight, anti-slip safety, and corrosion resistance with far less upkeep. Many customers say installation is surprisingly quick; I’d add that the absence of hot works permits on site is a quiet cost saver.

Industry trend, briefly

Budgets are moving from capex to opex scrutiny. As a result, FRP grating adoption is climbing in chemical processing, desalination, battery plants, and data-center water systems. Fire-retardant resins and UV-stable topcoats are now table stakes.

Technical snapshot

| Construction | Molded FRP, Pultruded FRP (bearing bar) |

| Resins | Orthophthalic, Isophthalic, Vinyl Ester (FR) |

| Panel sizes | ≈ 1000×3000 mm, 1220×3660 mm; custom on request |

| Thickness options | 25, 30, 38, 50 mm (real-world use may vary) |

| Mesh | Standard (38×38 mm), Mini, Micro (≈13×13 mm) |

| Surface | Grit anti-slip, concave, or smooth top |

| Typical flexural strength | ≈ 200–350 MPa (ASTM D790) |

| Fire performance | ASTM E84 (Class 1 options); ASTM D635 self-extinguishing |

| UV/weathering | UV-stabilized resins; tested to ISO 4892-2 (≈ 1000 h) |

| Service life | 25–30+ years in typical industrial exposure |

How it’s made (and tested)

Materials: E-glass roving + thermoset resin (ISO/VE), fillers, pigments, fire-retardant additives. Methods: molded lattice curing in heated dies; or pultrusion for high directional strength. Post-process: grit broadcast, edge banding, drilling, bonding. QC: flexural (ASTM D790), burn rate (ASTM D635), surface burning (ASTM E84), UV aging (ISO 4892-2). I guess the quiet hero is consistent wet-out—good shops obsess over it.

Applications we see weekly

- WWTP walkways and clarifier bridges

- Marine docks, ferry terminals, offshore skids

- Chemical plants, pickling lines, acid sumps

- Food & beverage washdown areas (micro-mesh)

- Battery manufacturing and data-center utility trenches

Advantages customers call out

- Up to ≈70% lighter than steel; fewer lifts, faster installs. - Non-corrosive in salt spray and many acids/alkalis. - Anti-slip grit keeps TRIR down in wet zones. - Electrically non-conductive and non-sparking.

Vendor comparison (quick take)

| Vendor | Strength | Lead Time | Certs/Testing | Notes |

| ZJ Composites (Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China) | Balanced cost/quality, deep customization | ≈ 2–4 weeks + transit | ASTM D790/E84/D635, ISO 4892-2 (reports on request) | Strong fabrication support |

| Local Steel Grating Fabricator | Fast local service | Often 1–2 weeks | Not applicable to FRP | Needs paint/galv maintenance |

| Generic FRP Trader | Lowest upfront price | Varies | Inconsistent reporting | Check resin grade carefully |

Customization options

Resin systems (ISO/VE), color coding, grit size, conductive options, fire-retardant formulations, edge capping, CNC cut-outs, stainless clips. Actually, micro-mesh tops are increasingly popular for high-heel safety and tool drop prevention.

Mini case notes

Wastewater retrofit, EU: 38 mm molded VE grating replaced corroded steel on aeration basins; install time cut by ≈30%, reported maintenance down 40% year-on-year.

Coastal ferry pier, APAC: Pultruded FRP with grit top; weight reduction ≈65% vs steel, easier night-shift swap-outs. Crew feedback was, surprisingly, most about slip resistance.

Note: Values are representative; project-specific verification and load tables should be requested. Comply with local codes and walkway standards (e.g., OSHA/EN) during design.

- ASTM D790: Standard Test Methods for Flexural Properties of Plastics

- ASTM E84: Surface Burning Characteristics of Building Materials

- ASTM D635: Rate of Burning and/or Extent/Time of Burning of Plastics

- ISO 4892-2: Plastics — Methods of exposure to laboratory light sources

- OSHA 1910 Subpart D: Walking-Working Surfaces

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025