loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Micro Mesh Grating: Corrosion-Proof, Anti-Slip—Why?

Micro-mesh FRP grating: what spec sheets don’t tell you (but installers do)

If you’re weighing corrosion-proof walkways or anti-slip platforms, you’ve probably heard about frp micro mesh grating. To be honest, the buzz isn’t just marketing. The newer micro-mesh formats have shrunk open areas to keep tools, high heels, and small debris from falling through, while staying surprisingly light and easy to install. I’ve toured a few facilities in Hebei and the trend is clear: molded micro mesh is moving from “nice-to-have” to standard spec in water, chemical, and marine jobs.

ZJ Composites’ Holiday Special Offers GRP FRP Gratings Fiberglass Grates come out of No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China. Their range (standard, mini, and micro) aims at one thing: lifetime cost. Less corrosion, fewer shutdowns, and lower lifting gear needs. In fact, many customers say the first maintenance cycle they skip basically pays for the upgrade.

Quick spec snapshot (real-world use may vary)

| Mesh aperture | ≈ 12.7 × 12.7 mm (micro-mesh) |

| Thickness options | ≈ 25 mm, 30 mm, 38 mm |

| Panel sizes | ≈ 1000 × 3000 mm, 1220 × 3660 mm; custom cutting available |

| Resin systems | Orthophthalic, Isophthalic, Vinyl Ester (FR), Phenolic |

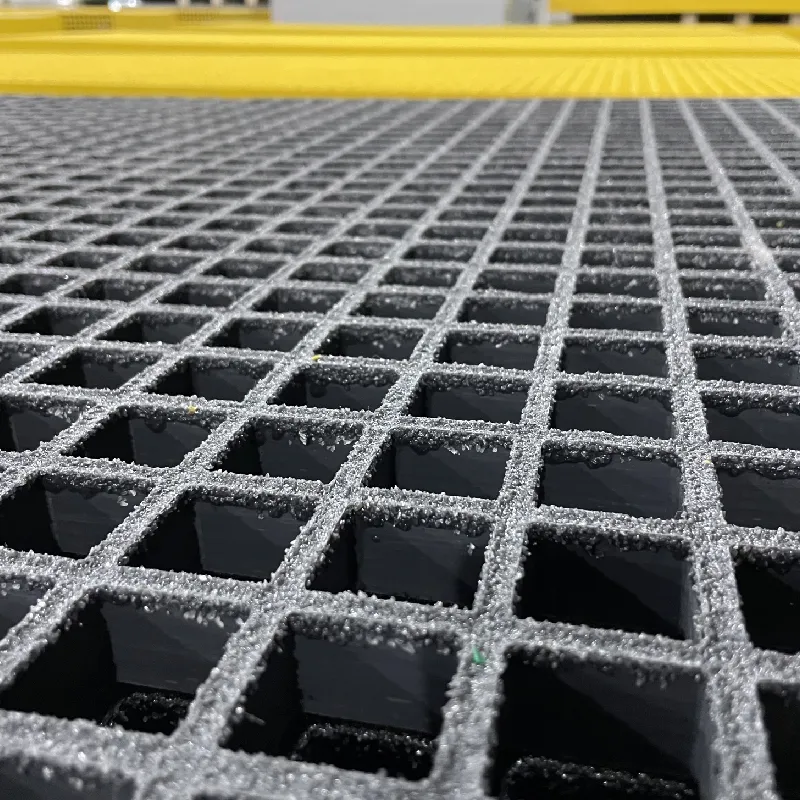

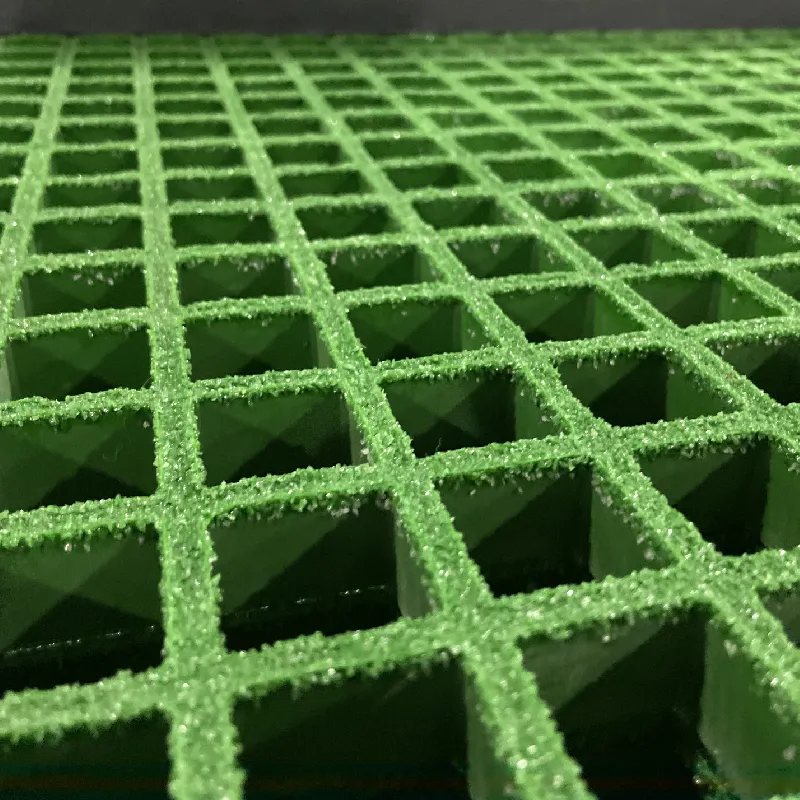

| Surface | Concave or grit (silica embedded) for wet-slip control |

| Fire performance | ASTM E84, flame spread index ≤ 25 (VE-FR formulations) [2] |

| Flexural strength | ≈ 150–220 MPa (ASTM D790) [3] |

| Service life | Designed 25+ years in typical coastal/industrial exposure |

How it’s made (and why it lasts)

Method: molded FRP. Continuous E-glass roving is layered in an open mold; resin (with pigments, UV inhibitors, and fire retardants where specified) is poured, then cured under heat. Demold, trim, then grit-coat if required. QA follows ASTM F3059 for grating performance in marine/industrial use where applicable [1]. Barcol hardness and dimensional checks are routine; flexural tests follow ASTM D790. I guess the boring consistency is actually the secret sauce.

Where it’s winning

- Wastewater plants and clarifiers (no rust, lower slip risk)

- Marine docks, shipboard catwalks (compliant with ASTM F3059 guidance) [1]

- Chemical processing and pickling lines (resin-tailored chemical resistance)

- Rooftop walkways, HVAC platforms, solar farms (lightweight, non-conductive)

- Food & beverage (closed micro mesh helps with small-object control)

Compared with steel, frp micro mesh grating avoids hot-work permits, reduces cranage, and doesn’t need paint. OSHA walking-working surface rules still apply, of course, but compliance is easier with pre-gritted tops and toe-board options [4].

Vendor snapshot (what buyers quietly compare)

| Vendor | Lead time | Certs/Tests | Customization | Indicative price | Warranty |

|---|---|---|---|---|---|

| ZJ Composites (Hebei) | ≈ 10–20 days | ASTM E84, D790; per-project F3059 reportable | Resin, color, grit, panel cut-to-size | ≈ $45–$85/m² | Up to 10 years |

| Import Brand A | ≈ 4–8 weeks | E84/D790; marine optional | Limited colors; fixed sizes | ≈ $70–$120/m² | 5–10 years |

| Budget Vendor B | ≈ 15–30 days | Basic COA; limited test data | Standard only | ≈ $35–$60/m² | 1–3 years |

Customization and QA

Options include conductive formulations, UV-boosted topcoats, edge banding, molded-in signage, and panel nesting to cut site waste. Typical paperwork: ISO 9001 factory QA, E84 flame report, D790 flexural test sheet, and—when marine—F3059 matrix. Internal slip tests (grit top) often show wet CoF ≥ 0.6; ask for a recent lot report. It seems trivial, but that grit grade matters on oily decks.

Field notes (two quick cases)

• Municipal wastewater walkways: swapped steel for frp micro mesh grating. Reported 40% installation time reduction and no repainting in year three; slip incidents dropped after changing to grit-top panels.

• Coastal fish farm: specified vinyl-ester micro mesh over brine tanks. After 18 months, no blistering; operators liked the “no-snag” feel for nets and boot cleats.

Trends to watch

More owners now request factory-cut kits, color coding by zone, and embedded RFID tags for asset tracking. Also seeing phenolic resins on enclosed platforms due to smoke-tox concerns. Honestly, that’s a good sign—frp micro mesh grating is maturing into a spec-driven product, not just a steel alternative.

Citations

- ASTM F3059 – Standard Specification for Fiber-Reinforced Polymer (FRP) Grating Used for Marine Construction. https://www.astm.org/f3059-14.html

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials. https://www.astm.org/e0084-23.html

- ASTM D790 – Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics. https://www.astm.org/d0790-17.html

- OSHA 29 CFR 1910 Subpart D – Walking-Working Surfaces. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910SubpartD

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025