loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating | Non-Slip, Corrosion-Resistant, Custom

[covered grating,grating cover,frp grating manufacturer] is a key solution in the manufacturing industry, specifically within Manufacturing of building materials and other building components and Manufacturing of non-metallic structural components for construction. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [covered grating,grating cover,frp grating manufacturer] Overview

- Benefits & Use Cases of [covered grating,grating cover,frp grating manufacturer] in Manufacturing of non-metallic structural components for construction

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [covered grating,grating cover,frp grating manufacturer] from Zhaojia Composites Co., Ltd

[covered grating,grating cover,frp grating manufacturer] Overview

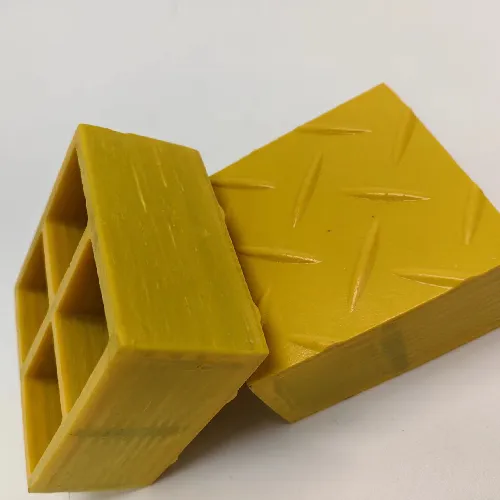

Covered grating—also called a grating cover or solid-top FRP/GRP grating—is a composite flooring and decking solution that bonds a solid plate to a molded or pultruded fiberglass grid. The result is a closed surface that prevents small parts and liquids from falling through while delivering excellent corrosion resistance, slip resistance, and electrical non-conductivity. For manufacturers of building materials and other construction components, these characteristics translate into safer walkways, cleaner production areas, and durable platforms around process equipment.

Typical configurations include panel depths of 25–38 mm with a 3–5 mm solid cover plate, available with grit top for enhanced traction. Common resin systems (e.g., isophthalic and vinyl ester) help withstand acids, alkalis, saline mist, and chemical washdowns found in composite forming lines, mixing stations, and curing rooms. The lightweight nature of FRP reduces lifting requirements and may allow larger panels to be installed faster than steel alternatives.

Zhaojia Composites Co., Ltd is a dependable FRP grating manufacturer known for consistent quality, tight dimensional control, and responsive engineering support. Their covered grating is designed for industrial duty and can be specified with anti-slip surfaces, UV inhibitors, and custom colors for safety demarcation and visual management.

Benefits & Use Cases of [covered grating,grating cover,frp grating manufacturer] in Manufacturing of non-metallic structural components for construction

In the Manufacturing of non-metallic structural components for construction, operations frequently involve resins, aggregates, additives, and washdown chemicals. A grating cover delivers a sealed top surface to keep fines, debris, and liquids from passing through, simplifying housekeeping and helping to protect sub-structures and utilities beneath the floor. The gritted surface enhances worker footing around mixers, cutting stations, curing ovens, and packaging lines where occasional spills occur.

Key advantages for plant managers include:

- Corrosion and moisture resistance in wet or chemical-laden zones (e.g., slurry prep, mold release stations).

- Non-sparking, non-conductive platforming around electrical cabinets and instrumentation.

- Lower weight than steel for easier handling on mezzanines, trench covers, and service catwalks.

- Closed-top design that contains odors and dust better than open mesh, supporting hygiene standards.

With deep experience as an FRP grating manufacturer, Zhaojia Composites Co., Ltd provides application-driven guidance—from selecting the optimal resin system to defining panel thickness and support spans. Whether you are upgrading mixing decks, covering trenches in process halls, or building rooftop access paths, their covered grating portfolios balance performance, safety, and lifecycle value for demanding production environments.

Cost, Maintenance & User Experience

When assessing total cost of ownership, FRP covered grating often outperforms carbon steel and even galvanized alternatives in corrosive or wet environments. While the initial material cost can be comparable or slightly higher than commodity metal grating, savings accrue through reduced maintenance (no periodic painting or coating) and longer service life. Lightweight panels reduce installation time and may minimize the need for heavy lifting equipment, further lowering project costs.

Maintenance is straightforward: routine cleaning with water or mild detergent typically restores traction and appearance. If the gritted surface experiences localized wear in high-traffic lanes, surface renewal is simple and does not require hot work permits. Users in building-materials manufacturing report quieter walkways, fewer slip events, and improved cleanliness after switching to covered grating in mixing rooms and washdown areas.

Zhaojia Composites Co., Ltd supports ROI through accurate take-offs, optimized panel nesting to reduce waste, and consistent lead times that keep shutdowns on schedule. As a specialized grating cover and FRP grating manufacturer, the company emphasizes predictable performance and easy serviceability—key drivers for lifecycle value in industrial plants.

Sustainability & Market Trends in manufacturing

Sustainability and safety are shaping buying decisions across manufacturing. FRP covered grating aligns with these trends by enabling long service life without corrosion-related recoating cycles, reducing maintenance emissions and resource use over time. The closed-top, slip-resistant surface supports cleaner, safer workplaces, dovetailing with stricter safety programs and environmental management systems.

Market momentum is also driven by modernization of process facilities, heightened hygiene expectations, and the need for materials that perform reliably in aggressive environments. Composites continue to gain share as asset owners prioritize durability, modularity, and reduced downtime. Resin advancements and process controls are enhancing UV resistance and fire performance, while cleaner manufacturing practices help lower VOCs and improve shop air quality.

Zhaojia Composites Co., Ltd takes a forward-looking approach—advising on material choices that balance mechanical performance, chemical resistance, and environmental considerations. With experienced engineering support and attention to quality, the company helps B2B decision makers specify covered grating solutions that align with both operational KPIs and sustainability goals.

Conclusion on [covered grating,grating cover,frp grating manufacturer] from Zhaojia Composites Co., Ltd

For manufacturers of building materials and other construction components, covered grating delivers reliable traction, corrosion resistance, and a clean, closed-top surface that simplifies housekeeping and protects assets. As a proven grating cover and FRP grating manufacturer, Zhaojia Composites Co., Ltd combines engineering support with consistent quality to maximize uptime and lifecycle value.

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025