loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

stainless steel filter vessel

Understanding Stainless Steel Filter Vessels Applications, Advantages, and Maintenance

Stainless steel filter vessels are essential components in various industrial applications where the separation of solids from fluids is crucial. These vessels, designed for durability and efficiency, are widely utilized in sectors such as pharmaceuticals, food and beverage, chemicals, and water treatment. This article will explore the features, advantages, and best practices for maintaining stainless steel filter vessels.

What are Stainless Steel Filter Vessels?

Stainless steel filter vessels are containers designed to hold filter media that separate particulates from liquids or gases. These vessels can be used in either a batch process or a continuous flow system. They are typically constructed from high-grade stainless steel, which offers excellent corrosion resistance, durability, and longevity. Commonly, these vessels come equipped with various types of filters, such as cartridge filters, bag filters, and screen filters, tailored to meet specific filtration needs.

Key Applications

1. Food and Beverage Industry In this sector, stainless steel filter vessels are used to ensure the purity of liquids and prevent contamination. They are essential in brewing, winemaking, and juice production, where maintaining product quality is paramount.

2. Pharmaceuticals The pharmaceutical industry employs these vessels to ensure sterile and uncontaminated products. They help in the filtration of active ingredients, ensuring that medications are safe for consumption.

3. Chemical Processing In chemical manufacturing, stainless steel filter vessels are used to separate catalyst materials, remove impurities, and facilitate the safe handling of hazardous substances.

4. Water Treatment Many water treatment facilities utilize these vessels for removing sediments and pollutants from water sources, making them suitable for safe consumption and use.

Advantages of Stainless Steel Filter Vessels

1. Corrosion Resistance Stainless steel is inherently resistant to corrosion, making it suitable for various environments, especially those that involve harsh chemicals and liquids.

2. Durability and Strength The robust construction of stainless steel filter vessels allows them to withstand high pressures and temperatures. This durability translates into a longer service life and reduced need for frequent replacements.

stainless steel filter vessel

3. Hygienic Properties Stainless steel naturally resists bacteria and other pathogens, making it an ideal choice for applications requiring a high level of hygiene, such as food and pharmaceuticals.

4. Versatility Stainless steel filter vessels can be designed and customized for specific processes and capacities, making them versatile for different industries.

5. Easy to Clean Due to their smooth surfaces, stainless steel vessels are easy to clean and sanitize, ensuring compliance with health and safety regulations.

Maintenance Best Practices

To ensure the longevity and efficiency of stainless steel filter vessels, regular maintenance is paramount. Here are some best practices to follow

1. Regular Inspections Periodically inspect the vessels for signs of wear, corrosion, or any structural damage. Early detection of issues can prevent costly repairs and downtime.

2. Cleaning Protocols Establish a routine cleaning schedule. Use appropriate cleaning agents and methods to avoid damaging the stainless steel surfaces. High-pressure rinsing and chemical cleaning agents designed for stainless steel can help remove residues effectively.

3. Monitor Performance Keep track of the operation performance of the filter vessels. Monitoring flow rates, pressure drops, and overall system efficiency can help identify when filter media needs replacement.

4. Follow Manufacturer Guidelines Always adhere to the manufacturer’s instructions regarding installation, operation, and maintenance of the filter vessels to ensure optimal performance.

5. Conduct Quality Checks Regularly test the filtrate for impurities to ensure the filtration process is functioning correctly and there are no leaks or bypasses in the system.

Conclusion

Stainless steel filter vessels are vital in maintaining the purity and safety of liquids across various industries. Their durability, corrosion resistance, and hygienic properties make them a preferred choice among manufacturers. By adhering to proper maintenance practices, businesses can ensure that their filtration systems operate efficiently and effectively, resulting in high-quality products and compliance with regulatory standards. Whether in food processing, pharmaceuticals, chemicals, or water treatment, investing in high-quality stainless steel filter vessels pays dividends in reliability and operational success.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

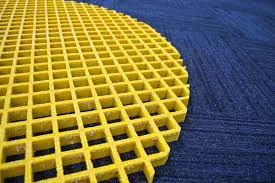

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025