loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Holiday Special Offers: Durable GRP FRP Gratings & Fiberglass Grates

Elevating Industrial Safety and Efficiency with Advanced GRP/FRP Gratings

In demanding industrial environments, the choice of structural materials is paramount for ensuring operational integrity, worker safety, and long-term cost-efficiency. Fiberglass Reinforced Polymer (FRP) and Glass Reinforced Plastic (GRP) gratings have emerged as superior alternatives to traditional metallic options, offering unparalleled resistance to corrosion, high strength-to-weight ratios, and extended service life. For a limited time, take advantage of our Holiday Special Offers GRP FRP Gratings Fiberglass Grates, designed to provide exceptional performance and value for your critical infrastructure projects.

This comprehensive guide delves into the technical specifications, manufacturing excellence, diverse applications, and profound advantages of these advanced composite materials, positioning them as an indispensable asset for modern industrial facilities seeking to optimize their operational frameworks and ensure compliance with stringent safety standards.

Industry Trends and Market Dynamics in Composite Gratings

The global market for GRP/FRP gratings is experiencing robust growth, driven by increasing industrialization, stringent safety regulations, and a growing emphasis on sustainable and durable infrastructure solutions. Key trends include:

- Shift Towards Non-Corrosive Materials: Industries such as petrochemical, chemical processing, and marine are increasingly replacing steel and aluminum with composites due to their superior corrosion resistance in aggressive environments. This minimizes downtime and extends asset life cycles.

- Enhanced Safety Features: Innovations in surface treatments (e.g., grit top, concave surfaces) provide enhanced slip resistance, while inherent non-conductivity reduces electrical hazards. Fire retardant formulations meet demanding safety codes like ASTM E-84 Class 1.

- Lightweighting for Logistics and Installation: The significantly lower weight of GRP/FRP gratings compared to metallic counterparts simplifies transportation, reduces installation time and labor costs, and lessens structural load requirements.

- Sustainability and Lifecycle Cost: While initial investment might be comparable or slightly higher, the extended service life, minimal maintenance, and recyclability of certain composites contribute to a lower total lifecycle cost and a more sustainable environmental footprint.

- Customization and Digital Integration: Advanced manufacturing techniques allow for highly customized grating solutions, while digital tools aid in design, stress analysis, and precise fabrication, leading to optimized performance for specific applications. The demand for Holiday Special Offers GRP FRP Gratings Fiberglass Grates reflects this market evolution towards value-driven, high-performance solutions.

According to industry reports, the global FRP gratings market is projected to reach over USD 1.5 billion by 2028, growing at a CAGR of approximately 6-7% from 2023. This growth is testament to the material's undeniable advantages across a spectrum of industrial sectors.

Manufacturing Process Flow: Engineering Excellence in GRP/FRP Gratings

The production of high-quality GRP/FRP gratings involves sophisticated processes that ensure product integrity and performance. There are primarily two methods: molded and pultruded. Our Holiday Special Offers GRP FRP Gratings Fiberglass Grates utilize both advanced manufacturing techniques, tailored to specific application requirements.

1. Molded GRP/FRP Gratings Process:

- Mold Preparation: Precision molds, often made from steel or aluminum, are meticulously cleaned and coated with a release agent to ensure easy demolding and a smooth final product finish.

- Resin Mix Formulation: Unsaturated polyester (e.g., Isophthalic, Orthophthalic) or vinyl ester resins are mixed with catalysts, pigments, UV inhibitors, and flame retardants according to precise formulations designed for specific chemical resistance and fire ratings.

- Fiberglass Lay-up: Continuous roving fiberglass strands are strategically placed within the mold cavities, alternating with layers of the prepared resin mixture. This ensures consistent mechanical properties in all directions.

- Curing: The mold, filled with resin and fiberglass, is subjected to heat and pressure, initiating a polymerization reaction that cures the resin and forms a solid, monolithic panel.

- Demolding & Finishing: Once cured, the grating panel is extracted from the mold, followed by trimming, edge finishing, and the application of anti-slip grit surfaces if required.

- Quality Control: Each panel undergoes rigorous inspection to meet dimensional tolerances, visual quality, and performance standards.

2. Pultruded GRP/FRP Gratings Process:

- Fiber Reinforcement Feed: Continuous fiberglass rovings and mats are pulled through a resin bath, where they are thoroughly impregnated with specialized resins (e.g., polyester, vinyl ester, phenolic).

- Pre-forming: The saturated fibers are then guided through a pre-forming die that shapes them into the desired grating profile (e.g., I-bar, T-bar, rectangular bar).

- Curing Die: The shaped, resin-impregnated profile is pulled through a heated steel die, where the resin cures, forming a rigid, continuous profile.

- Cutting & Assembly: The continuous pultruded profiles are cut to specific lengths, and then assembled using cross-rod connections to form the grating panels.

- Quality Assurance: Similar to molded gratings, pultruded panels undergo stringent quality checks for dimensional accuracy, mechanical properties, and finish.

Testing Standards & Service Life: All products adhere to international testing standards such as ISO 9001 for quality management, ASTM E-84 for flame spread and smoke development, ASTM D-638 for tensile properties, and ASTM D-790 for flexural properties. These rigorous standards ensure that our gratings deliver consistent, reliable performance. With proper installation and maintenance, our GRP/FRP gratings typically offer a service life exceeding 25 years, significantly outperforming metallic alternatives in corrosive environments.

Target Industries: Our gratings are critical components in petrochemical plants, offshore oil & gas platforms, metallurgy facilities, water and wastewater treatment plants, chemical processing, pulp & paper, mining, power generation, and marine applications. Their superior corrosion resistance, non-conductivity, and high strength-to-weight ratio make them ideal for these demanding sectors, contributing to significant energy savings through reduced maintenance and improved operational continuity.

Figure 1: High-performance GRP FRP Gratings in an industrial setting.

Technical Specifications: Unmatched Performance Parameters

The inherent properties of GRP/FRP materials, combined with precision manufacturing, result in gratings with outstanding technical performance. The Holiday Special Offers GRP FRP Gratings Fiberglass Grates provided are engineered to exceed industry expectations.

Typical Product Specification Table (Molded GRP Gratings - Isophthalic Polyester Resin):

| Parameter | Value/Specification | Relevant Standard |

|---|---|---|

| Standard Panel Size | 1220mm x 3660mm (4' x 12') | Industry Standard |

| Mesh Size | 38mm x 38mm (Square) | EN ISO 14122-3 |

| Panel Thickness | 25mm, 30mm, 38mm, 50mm | N/A |

| Resin Type | Isophthalic Polyester | ASTM D-4067 |

| Fiberglass Content | ~35% by weight | ASTM D-2584 |

| Ultimate Tensile Strength | ≥ 200 MPa | ASTM D-638 |

| Flexural Modulus | ≥ 8 GPa | ASTM D-790 |

| Fire Retardancy (Flame Spread) | Class 1 (FSI ≤ 25) | ASTM E-84 |

| Continuous Operating Temperature | -50°C to +100°C | N/A |

| Density | ~1.8 g/cm³ | ASTM D-792 |

| UV Resistance | Excellent (with UV inhibitors) | ASTM G-154 |

Note: Specific values may vary based on resin system, thickness, and mesh configuration. Consult product datasheets for precise load and deflection data.

Diverse Application Scenarios and Proven Experience

The versatility of GRP/FRP gratings enables their deployment across a myriad of challenging industrial and commercial applications. Our extensive experience deploying Holiday Special Offers GRP FRP Gratings Fiberglass Grates provides insights into optimal use cases:

- Chemical Processing Plants: Ideal for walkways, platforms, and trench covers where exposure to corrosive chemicals (acids, alkalis, solvents) would rapidly degrade metallic alternatives. Their chemical resistance ensures worker safety and structural longevity.

- Water & Wastewater Treatment Facilities: Used for access platforms, clarifier covers, and weir plates due to their excellent resistance to moisture, chlorine, and biological agents. The non-slip surface further enhances safety in wet conditions.

- Offshore Oil & Gas Platforms: Critical for decking, helicopter pads, and gangways. Their lightweight nature reduces overall platform weight, and superior corrosion resistance withstands harsh saltwater environments and UV exposure.

- Food & Beverage Processing: Hygienic, easy-to-clean, and resistant to wash-down chemicals, they are suitable for floorings and drainage covers, meeting stringent sanitation requirements.

- Power Generation Facilities: Utilized for cooling tower fills, catwalks, and electrical substations where non-conductivity is crucial for safety around live electrical equipment.

- Marine and Shipbuilding: Decks, docks, and shipbuilding platforms benefit from their lightweight, non-corrosive, and non-magnetic properties.

Customer Feedback Spotlight: "Implementing these FRP gratings in our sulfuric acid production area was a game-changer. Previously, steel gratings lasted only 1-2 years before significant corrosion required costly replacement. The new FRP gratings have been in place for 5 years with no signs of degradation, significantly reducing our maintenance budget and improving safety for our personnel." – Plant Manager, Major Chemical Manufacturer.

Technical Advantages of GRP/FRP Gratings

The adoption of GRP/FRP gratings over traditional materials offers a multitude of technical and operational advantages:

- Exceptional Corrosion Resistance: Impervious to a wide range of chemicals, acids, alkalis, saltwater, and harsh atmospheric conditions, ensuring longevity and reducing premature structural failure.

- High Strength-to-Weight Ratio: While significantly lighter than steel (approximately 1/4 the weight), FRP gratings possess comparable or superior load-bearing capabilities, simplifying handling and reducing supporting structure requirements.

- Non-Conductivity: Electrically non-conductive and thermally insulating, providing crucial safety in environments with electrical hazards and preventing heat transfer.

- Impact Resistance: Possesses excellent energy absorption characteristics, resisting permanent deformation from impacts that would bend or dent metallic gratings.

- Fire Retardancy: Engineered with fire-retardant resins, meeting stringent fire safety codes (e.g., ASTM E-84 Class 1), critical for confined spaces and industrial facilities.

- Low Maintenance: Does not rust, pit, or require painting. Its inherent color is molded throughout the product, reducing lifecycle costs significantly.

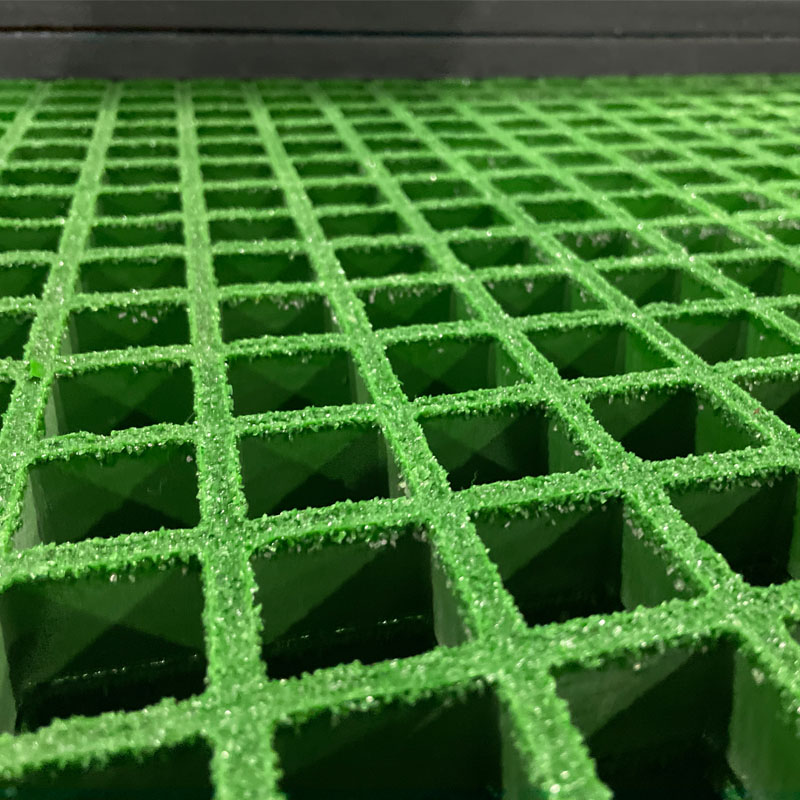

- Slip Resistance: Surfaces can be molded with integral grit tops or concave profiles, providing superior slip resistance even in wet or oily conditions, enhancing worker safety.

- UV Stability: Incorporates UV inhibitors to prevent degradation from prolonged sun exposure, crucial for outdoor applications.

- Ease of Fabrication: Can be cut and fabricated on-site with standard tools, reducing installation time and complexity.

Figure 2: Close-up of high-grip surface on GRP FRP Gratings.

Vendor Comparison: Why Choose Our Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Selecting the right supplier for GRP/FRP gratings is crucial for project success. While many vendors exist, our commitment to quality, customization, and customer support sets us apart. The current Holiday Special Offers GRP FRP Gratings Fiberglass Grates present an opportune moment to invest in superior products.

Comparative Analysis: Standard Vendor vs. Premium Solution Provider (Our Offerings)

| Feature | Standard Vendor | Our Premium Solution |

|---|---|---|

| Material Quality | Often generic, basic resin systems (e.g., Orthophthalic polyester). | High-grade Isophthalic or Vinyl Ester resins, specified for optimal chemical resistance and durability. Consistent fiberglass content. |

| Manufacturing Process | Standard molding/pultrusion, potentially less stringent QC. | State-of-the-art, ISO 9001 certified processes with multiple QC checkpoints and advanced curing. |

| Certifications | Basic compliance, limited third-party verification. | ISO 9001, ASTM E-84 Class 1, and various industry-specific approvals. Full material traceability. |

| Customization | Limited options for sizes, colors, or resin systems. | Extensive customization: panel dimensions, mesh configurations, resin types, colors, anti-slip finishes. Engineering support for bespoke designs. |

| Technical Support | Basic product information, less in-depth application guidance. | Dedicated engineering team, CAD drawings, load-deflection analysis, site survey assistance. |

| Warranty & Service Life | Standard 1-5 year warranty, expected service life 10-15 years. | Extended 10-year warranty, expected service life exceeding 25 years with minimal maintenance. |

| Lead Time & Fulfillment | Variable, often longer for non-standard items. | Optimized supply chain, typically 2-4 weeks for standard products, 4-8 weeks for custom solutions. Expedited options available. |

Customized Solutions for Unique Industrial Demands

Recognizing that every industrial project has unique requirements, we specialize in providing bespoke GRP/FRP grating solutions. Our engineering team collaborates closely with clients to design and manufacture gratings that precisely meet specific load capacities, chemical resistance profiles, environmental conditions, and installation constraints.

Customization options include:

- Panel Dimensions: Tailored lengths and widths to minimize on-site cutting and waste.

- Mesh Configurations: Varying opening sizes (e.g., micro-mesh for pedestrian safety, larger mesh for drainage) and bar profiles.

- Resin Systems: Selection of Isophthalic, Vinyl Ester, or Phenolic resins for specific chemical and fire resistance requirements.

- Colors: Custom colors to match corporate branding or improve visual safety demarcation.

- Surface Finishes: Concave, grit-top, or smooth surfaces depending on slip resistance needs and application.

- Load & Deflection Optimization: Engineering calculations to ensure optimal performance under specified loads.

Application Case Studies: Delivering Real-World Value

Our commitment to delivering high-performance solutions is demonstrated through successful projects across diverse industries. The advantages of our Holiday Special Offers GRP FRP Gratings Fiberglass Grates are evident in these real-world scenarios.

Case Study 1: Wastewater Treatment Plant Upgrade

Client: Municipal Wastewater Treatment Facility, North America

Challenge: The plant's existing steel walkways and trench covers in the primary treatment area were severely corroded by hydrogen sulfide (H₂S) and other aggressive chemicals present in the wastewater. This posed significant safety risks and required frequent, costly repairs and replacements, leading to operational downtime.

Solution: We provided custom-fabricated 38mm thick, 38x38mm mesh GRP molded gratings using a premium Vinyl Ester resin system known for its superior resistance to a broad spectrum of chemicals. The gratings were installed as new platforms, stair treads, and trench covers, specified with a grit-top surface for enhanced slip resistance in wet environments.

Results: The facility experienced an immediate improvement in safety due to the anti-slip surface and the non-corrosive nature of the material. After 3 years, the GRP gratings show no signs of corrosion or degradation, drastically reducing maintenance costs by an estimated 70% annually and eliminating the need for frequent replacements. The lightweight nature of the panels also expedited installation by 40% compared to traditional materials, minimizing disruption to plant operations.

Case Study 2: Offshore Wind Farm Access Platforms

Client: Leading Offshore Wind Energy Developer, Europe

Challenge: The client required robust, lightweight, and corrosion-resistant access platforms and walkways for their new offshore wind turbine foundations. Traditional steel options were too heavy, expensive to transport and install offshore, and susceptible to rapid corrosion in the harsh marine environment, increasing lifecycle costs and maintenance. Electrical safety was also a primary concern.

Solution: We supplied pultruded GRP gratings with an I-bar profile, specifically engineered for high load capacity and minimal deflection over longer spans. These gratings were made from an Isophthalic polyester resin with UV inhibitors and a highly aggressive grit surface. Their lightweight design facilitated helicopter transport and manual installation on the turbine structures.

Results: The GRP gratings significantly reduced the overall weight on the turbine foundations, leading to cost savings in structural design. Their inherent non-conductivity enhanced safety for maintenance personnel working near electrical components. The superior corrosion and UV resistance has ensured their integrity in the aggressive saltwater and constant sunlight conditions. Initial reports indicate projected maintenance cost reductions of 60% over a 20-year operational lifespan compared to conventional materials, coupled with enhanced safety ratings.

Trustworthiness & Support

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between GRP and FRP?

- A: GRP (Glass Reinforced Plastic) and FRP (Fiberglass Reinforced Polymer) are often used interchangeably. GRP is a specific type of FRP where glass fibers are the reinforcement. FRP is a broader term encompassing various fiber reinforcements (carbon, aramid, glass) within a polymer matrix. For gratings, GRP is the most common form of FRP.

- Q: Can these gratings be cut or modified on-site?

- A: Yes, GRP/FRP gratings can be safely cut and fabricated on-site using standard power tools equipped with appropriate abrasive blades (e.g., diamond-tipped). Proper ventilation and personal protective equipment (PPE) are essential to manage fiberglass dust. We also offer pre-cut and pre-fabricated panels to minimize on-site work.

- Q: What is the typical lead time for an order?

- A: For standard sizes and common resin types, lead times are typically 2-4 weeks. Customized orders or large volumes may require 4-8 weeks. We strive to meet urgent project deadlines and recommend discussing specific requirements with our sales team.

- Q: What kind of warranty is offered?

- A: We provide an industry-leading 10-year limited warranty against manufacturing defects and premature material degradation under normal operating conditions. Full warranty details are available upon request.

Lead Time & Fulfillment

Our advanced manufacturing capabilities and streamlined logistics ensure efficient order fulfillment. We maintain a substantial inventory of popular configurations to support rapid deployment. For projects requiring specific dimensions, resin systems, or colors, our production team works diligently to meet agreed-upon delivery schedules, typically within 2-8 weeks depending on complexity.

Warranty Commitments

Our GRP/FRP gratings are built to last, backed by a comprehensive 10-year warranty. This warranty covers material integrity and manufacturing defects, providing our clients with peace of mind and assurance in the long-term performance of their investment. Our commitment to quality control, adhering to ISO 9001 standards, ensures that every product leaving our facility meets the highest benchmarks.

Customer Support Information

Our dedicated customer support team and technical experts are available to assist with product selection, technical inquiries, installation guidance, and after-sales service. We offer comprehensive support from initial consultation through to project completion and beyond. For immediate assistance or to request a quote for our Holiday Special Offers GRP FRP Gratings Fiberglass Grates, please visit our website or contact our sales department directly. Our extensive network of satisfied partner clients, including leading industrial firms across petrochemical, maritime, and public infrastructure sectors, attests to our reliability and service quality over decades of operation.

References

- ASTM International. "Standard Test Methods for Tensile Properties of Plastics." ASTM D638-14.

- ASTM International. "Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials." ASTM D790-17.

- ASTM International. "Standard Test Method for Surface Burning Characteristics of Building Materials." ASTM E84-23.

- ISO (International Organization for Standardization). "Quality management systems – Requirements." ISO 9001:2015.

- American Composites Manufacturers Association (ACMA). "FRP Composites in Infrastructure: A Guide."

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025