loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

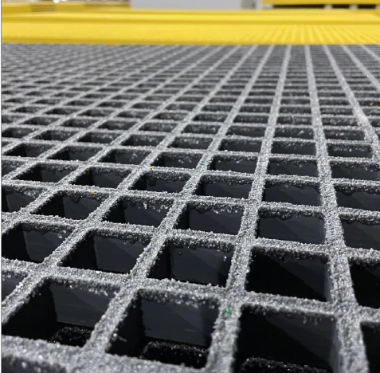

Fire-Retardant FRP Grating Panels

Fire-retardant FRP grating panels—including versatile FRP grating and durable grating FRP—have become a go-to choice for high-safety environments like factories, power plants, and commercial buildings, thanks to their ability to resist flames while maintaining structural strength. ZJ Composites, a leader in composite materials with a focus on quality and innovation, empowers wholesalers to supply top-tier fire-retardant FRP grating panels that meet global safety standards. With perfect testing equipment, strong technical support, and a product lineup spanning FRP grating, pultrusion profiles, and pressure vessels, ZJ Composites has earned trust worldwide—its products are sold globally and backed by a customer service tenet of meeting client needs with optimal solutions. Unlike traditional metal or wood grating, ZJ’s fire-retardant grating FRP combines light weight, corrosion resistance, and flame resistance, making it ideal for scenarios where safety and durability coexist. For wholesalers catering to construction firms, industrial facilities, or safety-focused projects, partnering with ZJ Composites means accessing FRP grating solutions that don’t just meet safety codes—they set a benchmark for reliable performance in high-risk environments.

Flame Resistance Mechanism of FRP Grating Panels

- Special Additive Integration: ZJ Composites’ fire-retardant FRP grating panels get their flame resistance from specialized additives mixed into the FRP matrix during production. These additives (like halogen-free flame retardants) suppress combustion by forming a protective char layer when exposed to high heat—this layer blocks oxygen from reaching the core material, stopping flames from spreading. Unlike standard FRP grating that melts or burns rapidly, ZJ’s fire-retardant variant self-extinguishes within seconds of removing the ignition source, meeting strict safety standards (e.g., UL94 V-0). For example, in a power plant using ZJ’s grating FRP for walkways, a small electrical spark won’t escalate into a fire, protecting both personnel and equipment. Wholesalers can highlight this mechanism to clients, as it’s the core reason fire-retardant FRP grating panels are essential for high-safety zones.

- Low Smoke and Toxic Gas Emission: During a fire, traditional materials often release toxic smoke that endangers lives—but ZJ’s fire-retardant FRP grating emits minimal smoke and low-toxicity gases. This is critical for enclosed spaces (like underground parking garages or factory interiors) where smoke inhalation is a leading cause of fire-related injuries. ZJ’s rigorous testing ensures its FRP grating panels meet smoke density and toxicity standards, making them a safer choice than metal grating (which can conduct heat and spread fire) or wood grating (which burns rapidly). Wholesalers can emphasize this safety benefit to clients, as it aligns with global fire safety regulations and protects end-users.

Key Advantages of ZJ Composites’ FRP Grating

|

Advantage |

Details for Fire-Retardant FRP Grating |

Ideal Application Scenarios |

ZJ Composites’ Production Edge |

Wholesaler Value (Market Fit) |

|

Flame Resistance |

Self-extinguishing (UL94 V-0); minimal smoke/toxic gas emission |

Power plants, chemical factories, commercial building walkways |

Specialized flame-retardant additives; strict testing |

Caters to industrial distributors needing code-compliant grating |

|

Corrosion Resistance |

Resists acids, alkalis, and moisture—no rusting or degradation |

Wastewater treatment plants, marine facilities |

High-quality FRP matrix; anti-corrosion coating |

Fits clients in harsh-environment industries |

|

Light Weight |

70% lighter than steel grating; easy to transport and install |

High-rise building mezzanines, temporary construction sites |

Precision pultrusion process; lightweight yet strong design |

Appeals to construction firms seeking labor cost savings |

|

Low Maintenance |

Smooth surface; no painting or rust removal needed; easy to clean |

Hospital corridors, food processing plants |

Durable FRP material; resistant to wear and staining |

Helps wholesalers offer long-term cost-saving solutions |

Application Scenarios for Fire-Retardant Grating FRP

- Industrial Facilities: Grating FRP is a staple in chemical plants, oil refineries, and power plants—areas where fire risk and corrosion are constant concerns. ZJ’s fire-retardant FRP grating panels are used for walkways, platform flooring, and equipment supports: their flame resistance prevents fire spread, while corrosion resistance stands up to chemicals and moisture. For example, a chemical factory using ZJ’s FRP grating for tank tops won’t face rust-related maintenance or fire risks from sparks, reducing downtime and safety incidents. Wholesalers can market this to industrial supply chains, as grating FRP replaces high-maintenance steel grating and meets strict industry safety codes.

- Commercial and Public Spaces: In shopping malls, airports, and hospitals, fire-retardant FRP grating is used for ceiling panels, stair treads, and ventilation grilles. Its light weight eases installation in large buildings, and flame resistance ensures compliance with public safety regulations. Unlike metal grating that can be slippery when wet, ZJ’s FRP grating panels have a non-slip surface (via textured patterns), reducing fall risks in high-traffic areas. Wholesalers can highlight this dual benefit (safety + functionality) to commercial construction distributors, as it addresses both fire safety and user comfort.

Installation and Maintenance Tips for FRP Grating Panels

- Simplified Installation: ZJ’s FRP grating panels are designed for easy installation—they’re lightweight (no heavy lifting equipment needed) and come with pre-drilled holes for fasteners. For wholesalers, this means clients (like construction teams) save time and labor costs compared to installing steel grating. ZJ also provides installation guides to help clients avoid common mistakes (e.g., over-tightening fasteners, which can damage the grating). Wholesalers can include these guides with bulk orders, reducing client questions and ensuring smooth installation.

- Minimal Maintenance Routine: Fire-retardant FRP grating needs little upkeep—occasional cleaning with soap and water removes dirt and debris, and no painting or rust treatment is required. ZJ’s grating FRP resists staining from oils, chemicals, or food residues, making it ideal for food processing plants or commercial kitchens. For wholesalers, this low-maintenance feature is a key selling point: it reduces long-term costs for end-users, making FRP grating panels a more attractive option than high-maintenance steel or wood grating. Wholesalers can also recommend ZJ’s specialized cleaning products (for tough stains) as add-ons, increasing order value.

FRP Grating FAQS

Do ZJ Composites’ FRP Grating Panels Meet Global Fire Safety Standards?

Yes—ZJ’s fire-retardant FRP grating panels meet international standards like UL94 V-0 (flame resistance), ASTM E84 (smoke density), and GB 8624 (Chinese fire safety code). They’re tested rigorously in ZJ’s in-house labs (equipped with perfect testing equipment) to ensure compliance, making them suitable for global markets. Wholesalers can confirm specific standards for clients in regions like Europe (CE) or North America (UL), ensuring the grating meets local regulations.

How Does Grating FRP Compare to Steel Grating in Terms of Strength?

ZJ’s grating FRP has a strength-to-weight ratio 2x higher than steel grating—while it’s 70% lighter, it can handle similar load capacities (e.g., 500kg/m² for standard panels). For applications like industrial walkways or platform flooring, this means FRP grating is just as strong as steel but easier to install and transport. Wholesalers can share load capacity charts with clients, helping them choose the right grating for their needs without sacrificing strength.

Can FRP Grating Panels Be Customized for Specific Sizes or Shapes?

Absolutely—ZJ Composites offers custom FRP grating panels (size, thickness, and texture) for bulk orders. Whether clients need narrow strips for stair treads or large panels for factory floors, ZJ’s technical team uses precision pultrusion and molding processes to create tailored solutions. Wholesalers can work with ZJ’s customer service to fulfill custom requests, catering to niche projects (like curved walkways or irregularly shaped platforms) that standard grating can’t address.

What Is the Lifespan of ZJ’s Fire-Retardant FRP Grating?

With proper installation and minimal maintenance, ZJ’s fire-retardant FRP grating has a lifespan of 15–20 years—far longer than wood grating (5–7 years) or uncoated steel grating (10–12 years). Its corrosion resistance and flame-retardant additives don’t degrade over time, ensuring consistent performance. Wholesalers can highlight this long lifespan to clients, as it translates to lower replacement costs and higher return on investment for end-users.

Does ZJ Composites Offer Bulk Shipping for FRP Grating to Global Markets?

Yes—ZJ Composites has extensive experience in global shipping, with products sold worldwide. For wholesalers, ZJ provides bulk packaging (standard crates or custom packaging to prevent damage) and coordinates with reliable logistics partners to deliver FRP grating and grating FRP to regions like Europe, North America, and Southeast Asia. ZJ’s customer service team also assists with customs documentation, ensuring smooth delivery. Wholesalers can rely on ZJ’s global supply chain to meet large orders on time, supporting their business growth. To explore ZJ Composites’ fire-retardant FRP grating panels, FRP grating, grating FRP, and full range of FRP products—plus bulk ordering and customization options—visit our company webpage today.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025