loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

tata frp vessel

The Advantages of TATA FRP Vessels in Modern Engineering

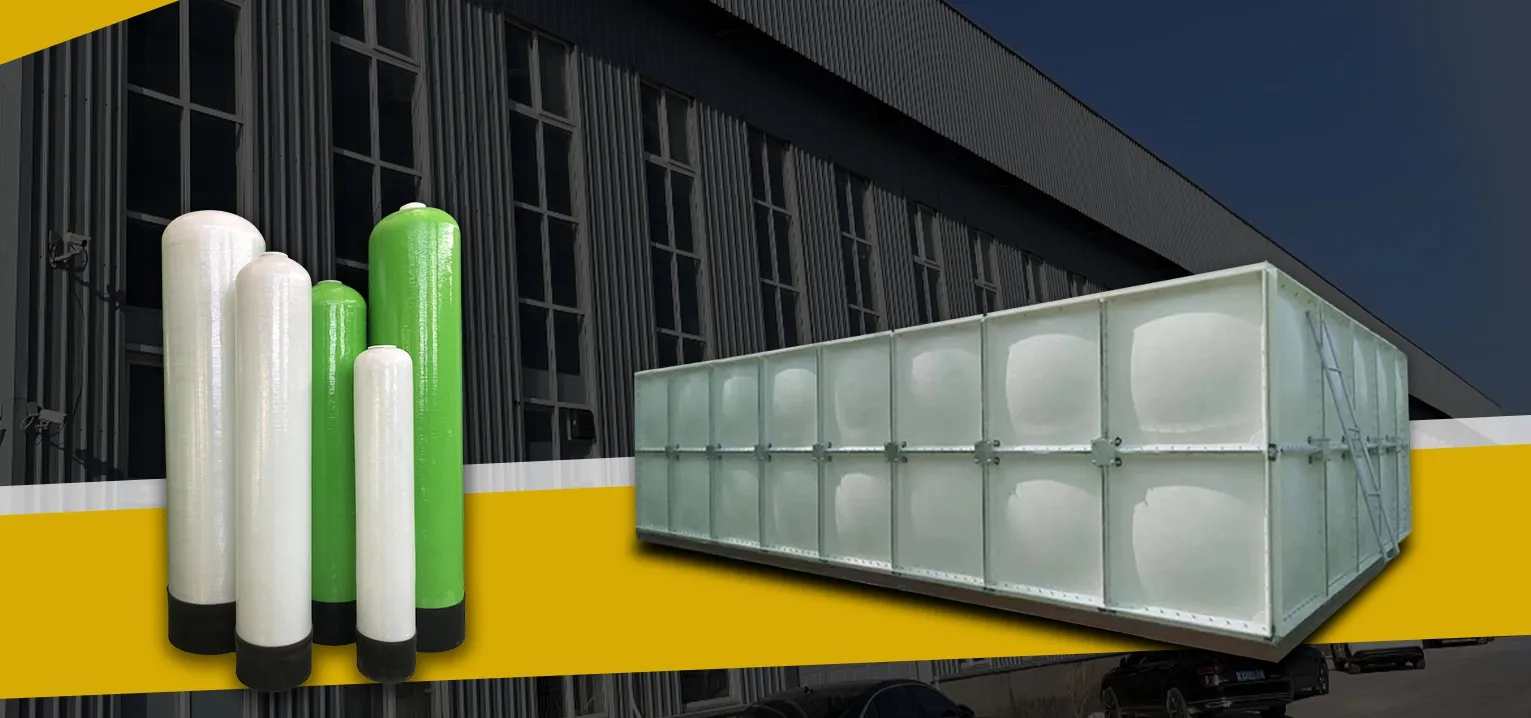

In recent years, the demand for innovative materials in engineering and construction has grown exponentially. One remarkable development in this field is the use of Fiber Reinforced Plastics (FRP), notably in the manufacturing of vessels and tanks. Among the leading manufacturers of FRP products is TATA, a company synonymous with quality and reliability. TATA's FRP vessels offer a range of benefits that make them suitable for various industrial and commercial applications.

The Advantages of TATA FRP Vessels in Modern Engineering

Another noteworthy benefit of TATA FRP vessels is their exceptional resistance to corrosion. Unlike metal tanks that may succumb to rust and degradation due to chemical exposure, FRP vessels are highly resistant to a wide range of corrosive substances, including acids, alkalis, and salts. This property results in a longer lifespan for the vessels and reduces maintenance costs significantly. In industries such as chemical processing, wastewater treatment, and marine applications, where corrosive environments are commonplace, TATA FRP vessels prove to be a robust solution.

tata frp vessel

Durability is another cornerstone of TATA FRP vessels. They are engineered to withstand harsh environmental conditions, including extreme temperatures and heavy loads. Their mechanical strength is enhanced through the strategic placement of fibers within the resin matrix, ensuring that these vessels can sustain their structural integrity even under challenging circumstances. This durability not only improves safety but also ensures that the vessels perform reliably over an extended period, minimizing downtime.

Furthermore, TATA FRP vessels are customizable to meet specific industry needs. The versatility of FRP materials allows for the design of vessels in various shapes, sizes, and configurations. This adaptability makes TATA FRP vessels ideal for numerous applications, ranging from industrial storage tanks to specialized containment units for water and wastewater. The ability to tailor vessel specifications to the operational requirements of a facility enhances efficiency and effectiveness in processes involving fluid storage and transport.

In addition to these technical benefits, the environmental impact of using TATA FRP vessels cannot be overlooked. The lightweight and durable nature of FRP materials leads to lower energy consumption during production and transportation. Furthermore, their longevity reduces the need for frequent replacements, leading to decreased waste. As industries increasingly prioritize sustainability, incorporating FRP solutions aligns with broader environmental goals.

In conclusion, TATA FRP vessels represent a formidable advancement in modern engineering, offering a blend of lightweight construction, corrosion resistance, mechanical durability, customization, and environmental sustainability. As industries across the globe continue to evolve and embrace more innovative solutions, the demand for reliable and efficient storage options like TATA FRP vessels is likely to increase. Their unique properties make them a preferred choice for engineers and decision-makers looking to enhance operational efficiency while minimizing environmental impact. As we move forward, TATA's commitment to quality and innovation will undoubtedly position them at the forefront of the FRP vessel market, setting new standards for excellence in the industry.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025