loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

design and utilization of sectional storage tanks for efficient fluid management

Understanding Sectional Tanks A Comprehensive Overview

Sectional tanks, also known as modular or segmented tanks, have gained significant popularity in various industries for their versatility, efficiency, and ease of installation. These tanks are constructed from multiple sections that can be assembled on-site, making them an ideal solution for water storage, chemical processing, and other applications requiring substantial liquid containment. This article delves into the characteristics, benefits, applications, and factors to consider when choosing sectional tanks.

Characteristics of Sectional Tanks

Sectional tanks are typically made from materials such as fiberglass, stainless steel, or carbon steel, which are chosen based on the specific needs of the application. The modular design allows for customization in terms of size, shape, and capacity, catering to the requirements of different projects. They can be constructed in various configurations to fit specific space constraints, making them suitable for both urban and rural environments.

One of the key features of sectional tanks is their ability to be disassembled and relocated. This makes them a preferred choice for temporary installations or industries that anticipate changing needs. Additionally, sectional tanks can be easily expanded by adding more sections, providing a flexible storage solution as demands increase.

Benefits of Sectional Tanks

The benefits of sectional tanks are numerous. Firstly, their modular design simplifies transport and installation. Assembling a sectional tank on-site reduces labor costs and the time required for setup. Moreover, these tanks often require less foundation work compared to traditional tanks, further minimizing installation time and costs.

Secondly, the ability to customize these tanks according to specific requirements ensures that businesses can optimize their storage solutions without sacrificing quality or performance. This adaptability is particularly beneficial in industries like agriculture, manufacturing, and water treatment, where various liquids may be stored in different capacities and conditions.

Another advantage is the durability of sectional tanks

. Made from high-quality materials, they are resistant to corrosion and can withstand harsh environmental conditions. This resilience translates into lower maintenance costs and improved longevity, which is crucial for businesses looking to maximize their investment.sectional tanks

Applications of Sectional Tanks

Sectional tanks have diverse applications across multiple sectors. In the agricultural field, they are commonly used for rainwater harvesting, irrigation, and chemical storage. The modularity allows farmers to scale their systems according to seasonal needs or changes in crop types.

In the industrial sector, sectional tanks serve critical functions such as the storage of raw materials, finished products, or waste products. Their ability to hold chemicals safely makes them vital in pharmaceuticals, food processing, and chemical manufacturing. Additionally, municipal water treatment facilities utilize sectional tanks for sedimentation and effluent treatment processes.

Factors to Consider When Choosing Sectional Tanks

When selecting sectional tanks, several factors should be taken into account. First, assess the liquid's properties—its temperature, pH, and chemical composition—to ensure that the tank material is compatible. Second, consider the required storage capacity and site dimensions to determine the appropriate size and layout of the tank.

It is also essential to evaluate local regulations and standards regarding water storage and environmental impact to ensure compliance. Lastly, consult with manufacturers or industry experts to select a tank that meets both current and future needs effectively.

Conclusion

Sectional tanks provide an innovative solution for various storage challenges faced by industries today. Their modular design, durability, and flexibility make them an attractive option for businesses seeking efficient, scalable, and cost-effective liquid storage solutions. As industries evolve and grow, sectional tanks will continue to play a crucial role in meeting the demands of liquid containment and storage.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

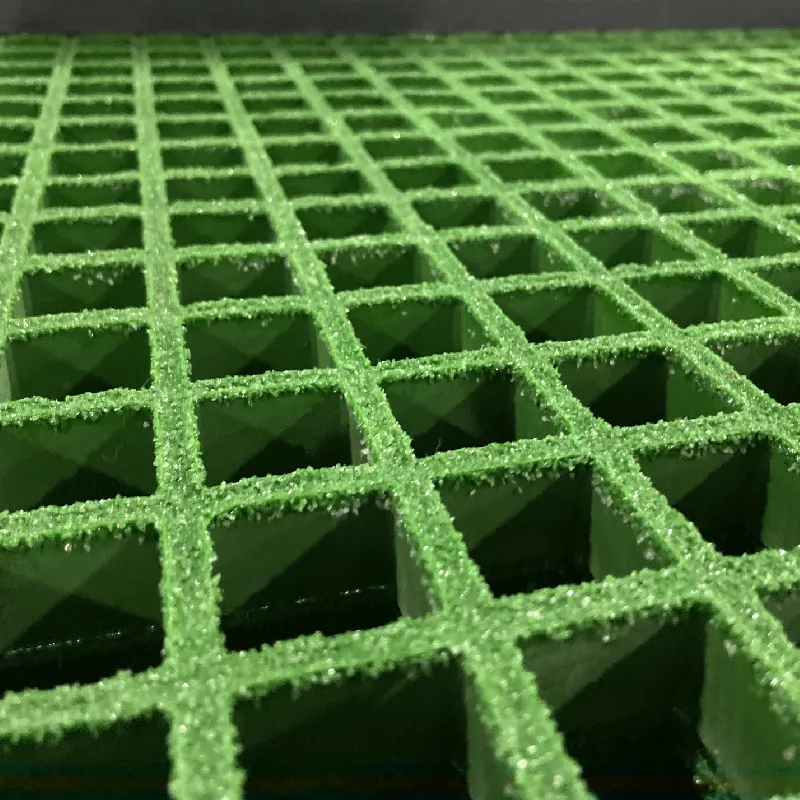

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025