loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring Advanced Applications of Grating in Fiber Reinforced Polymers for Modern Engineering Solutions

The Future of Grating Advancements in FRP (Fiber Reinforced Polymer) Technology

Fiber Reinforced Polymer (FRP) grating has emerged as a game-changer in various industries, offering a lightweight, durable, and corrosion-resistant alternative to traditional steel and fiberglass gratings. As industries seek more sustainable and efficient materials, the growing adoption of FRP grating reflects a shift towards innovative solutions that meet the demanding requirements of modern infrastructure.

Understanding FRP Grating

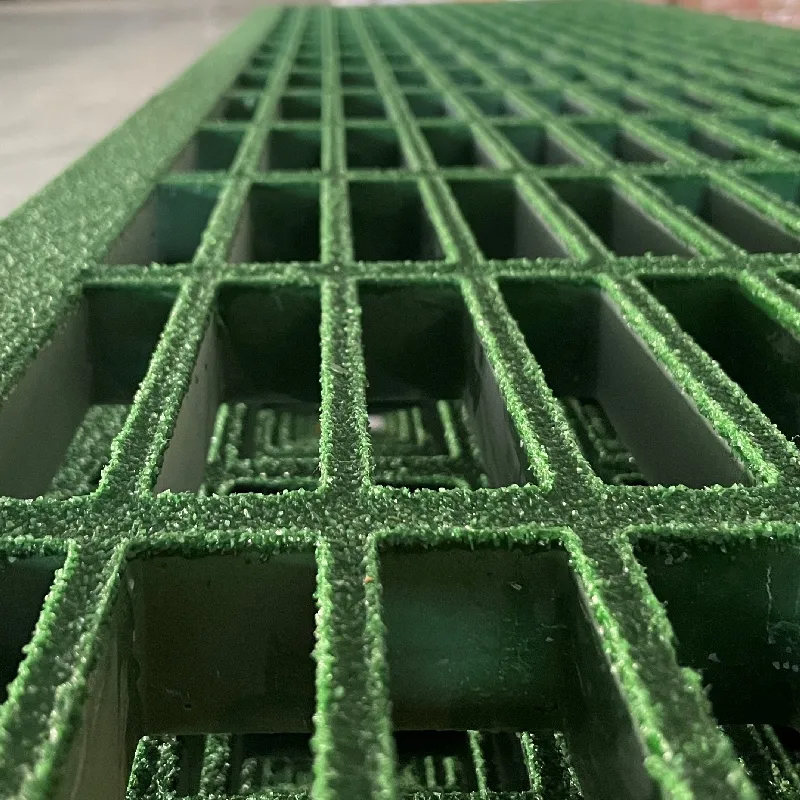

FRP grating is comprised of a polymer matrix reinforced with fiber materials, such as glass or carbon. This combination not only enhances mechanical strength but also provides significant resistance to environmental factors such as chemicals and moisture. Its inherent properties make FRP grating suitable for a multitude of applications, including industrial flooring, walkways, and platform structures.

The versatility of FRP grating is further highlighted by its customization options. Manufacturers can produce various sizes, shapes, and colors to meet specific project requirements. Additionally, FRP grating can be designed with surface textures that provide improved slip resistance, ensuring safety in challenging environments.

Key Advantages of FRP Grating

One of the foremost advantages of FRP grating is its lightweight nature. Weighing significantly less than steel, FRP grating is easier to handle, transport, and install, which can lead to substantial cost savings in labor and logistics. Moreover, its lower weight reduces the burden on structural supports, allowing for the design of lighter frameworks that can lower overall construction costs.

FRP grating is inherently resistant to corrosion, a common problem in industries involving chemicals, wastewater, or marine environments. Unlike traditional materials that may deteriorate over time when exposed to harsh elements, FRP maintains its structural integrity, thereby extending the lifespan of installations. This longevity translates into reduced maintenance costs and enhanced reliability, making it a preferred choice for industries seeking durability.

Environmental Sustainability

grating frp

As global industries continue to focus on sustainability, FRP grating presents significant environmental benefits. The production process for FRP is often more energy-efficient compared to traditional materials. Additionally, FRP is typically recyclable, and manufacturers are increasingly adopting eco-friendly production practices. By utilizing FRP grating, companies can reduce their carbon footprint and contribute to a more sustainable future.

Applications Across Industries

The applications of FRP grating span various sectors, including chemical processing, petroleum, food and beverage, and municipal infrastructure. In chemical plants, the grating’s resistance to corrosive substances makes it a reliable choice for flooring and walkways. Similarly, in wastewater treatment facilities, FRP grating’s durability ensures it can withstand continuous exposure to harsh conditions.

In the construction industry, FRP grating is used in both commercial and residential projects. It can be utilized for balconies, staircases, and pedestrian walkways. Its aesthetic appeal and customizable designs allow architects to incorporate it into modern designs while promoting safety and efficiency.

Challenges and Considerations

Despite its numerous advantages, there are still challenges associated with FRP grating. Cost can be a barrier, as the initial investment in FRP may be higher than traditional materials. However, stakeholders must consider the long-term savings associated with lower maintenance and replacement costs. Additionally, the appropriate selection of FRP materials and designs is critical to ensuring compliance with local building codes and regulations.

Conclusion

As industries continue to innovate and prioritize sustainability, FRP grating stands out as a key material in modern applications. Its lightweight, corrosion-resistant, and customizable features make it an ideal choice for various environments. By embracing FRP technology, industries can enhance their infrastructure while reducing their environmental impact and ensuring safety in operations. The future of FRP grating looks promising, with ongoing advancements set to meet the ever-evolving demands of today’s world.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025