loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp pultruded profiles

Understanding FRP Pultruded Profiles A Comprehensive Overview

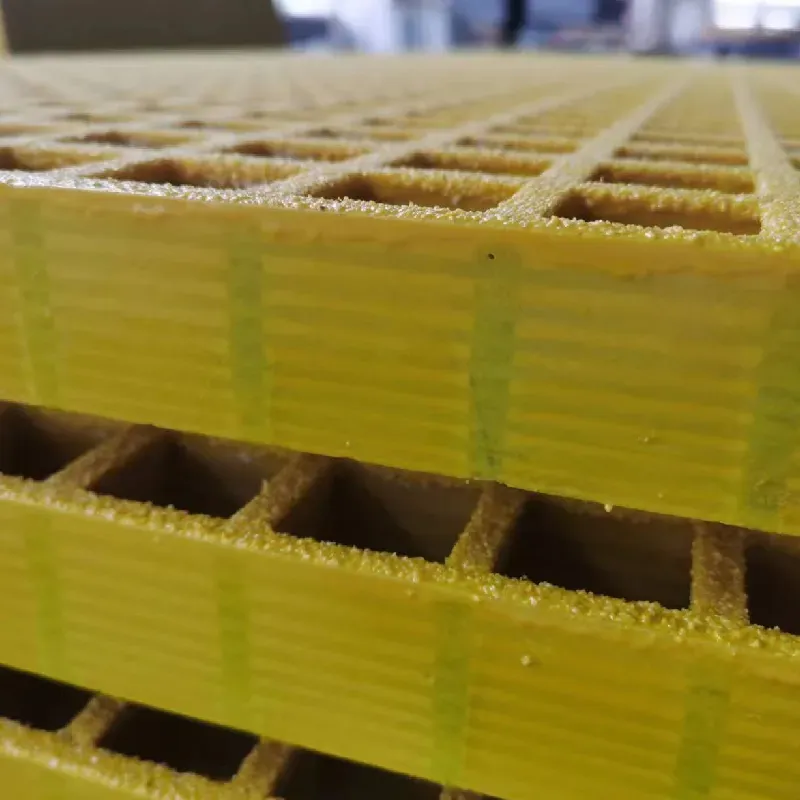

Fiber Reinforced Polymer (FRP) pultruded profiles have garnered significant attention in recent years, primarily due to their exceptional strength-to-weight ratio and resistance to corrosion. These materials represent a revolutionary leap in engineering and construction, enabling the design and implementation of components that were previously deemed unfeasible with traditional materials.

What are Pultruded Profiles?

Pultrusion is a manufacturing process used to create continuous lengths of composite materials. During this process, reinforcing fibers, typically glass or carbon, are pulled through a resin bath and then through a heated die. This die shapes the material into the desired profile while curing the resin, resulting in a strong and lightweight component. The resulting pultruded profiles can be cut to any length, making them versatile for various applications.

Properties of FRP Pultruded Profiles

One of the standout features of FRP pultruded profiles is their excellent mechanical properties. They are designed to withstand significant loads while remaining lightweight. This characteristic is particularly beneficial in applications where weight savings are crucial, such as in the aerospace, automotive, and construction industries.

Additionally, FRP profiles exhibit remarkable resistance to environmental factors. Unlike traditional materials such as steel, which can corrode over time, FRP materials are impervious to moisture, chemicals, and UV radiation. This resistance extends the lifespan of components made from FRP, reducing maintenance costs and replacement frequency.

Another vital property of FRP pultruded profiles is their thermal insulation capabilities. They are poor conductors of heat, making them excellent choices for applications requiring thermal resistance. This characteristic is especially useful in the construction of energy-efficient buildings, where controlling temperature is a priority.

Applications of FRP Pultruded Profiles

frp pultruded profiles

The versatility of FRP pultruded profiles has led to their widespread use across various industries. In the construction sector, they are utilized for a range of applications including structural beams, columns, and decking systems. Their lightweight nature makes them easier to handle and install, leading to reduced labor costs and expedited project timelines.

In the electrical sector, FRP profiles are used for utility poles and components of electrical enclosures. The non-conductive nature of FRP materials makes them safer alternatives to metal components, minimizing risks associated with electrical hazards.

Additionally, the marine industry benefits from FRP pultruded profiles due to their resistance to saline environments. They are commonly used for boat components, docks, and bridges, where exposure to water and environmental challenges often leads to degradation of traditional materials.

Economic Advantages

While the initial cost of FRP profiles may be higher than traditional materials, the long-term economic benefits are significant. The durability and low maintenance requirements associated with FRP components often lead to lower lifecycle costs. Project timelines benefit from the ability to quickly install these lightweight materials, allowing for faster project completions.

Furthermore, as awareness grows regarding sustainability and environmental concerns, the manufacturing of FRP profiles can include recycled materials, contributing to greener construction practices. Their longevity contributes to reduced waste and resource consumption over time.

Conclusion

FRP pultruded profiles represent a remarkable advancement in material science and engineering. Their unique properties—such as high strength-to-weight ratio, corrosion resistance, and thermal insulation—make them suitable for a range of demanding applications across multiple industries. As technology advances and manufacturing processes continue to evolve, the scope of applications for FRP pultruded profiles is expected to expand, further emphasizing their importance in modern construction and engineering solutions.

As industries continue to seek sustainable and efficient solutions, FRP pultruded profiles will likely play a key role in shaping the future of infrastructure and manufacturing, paving the way for innovative designs and successful project outcomes.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025