loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

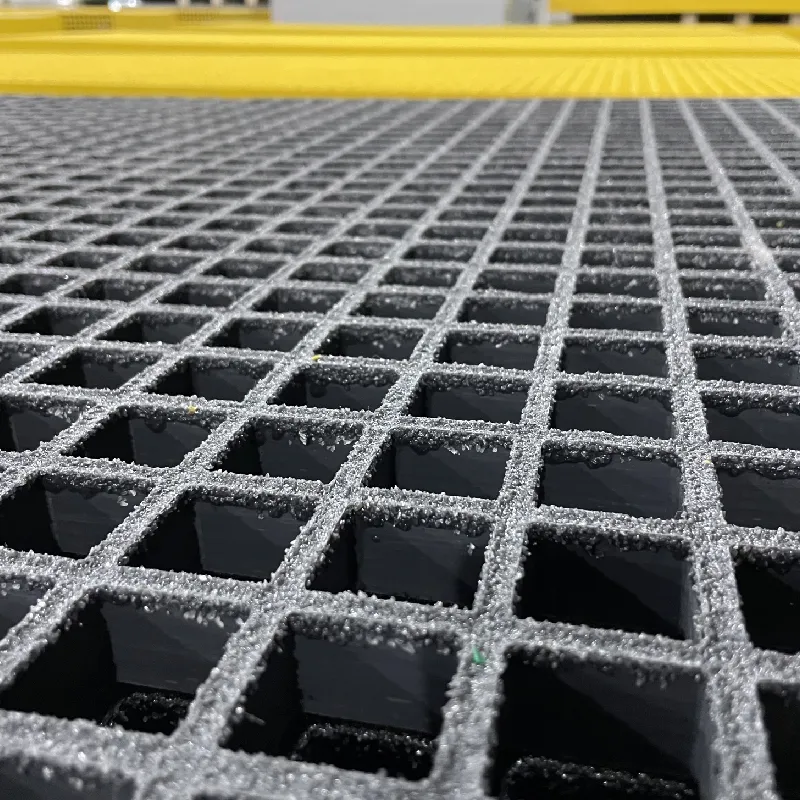

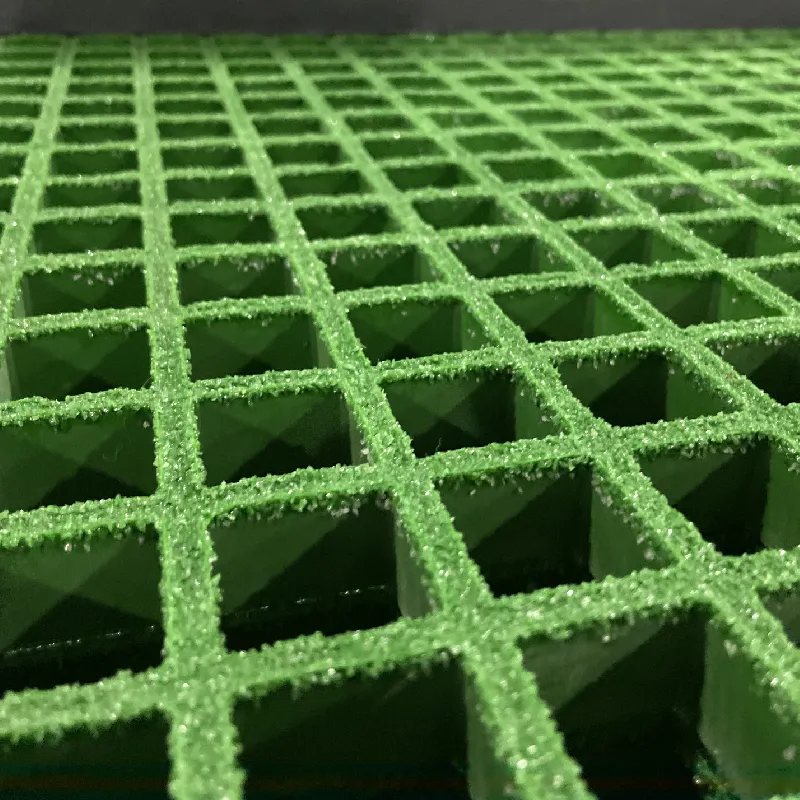

FRP Micro Mesh Grating: Durable & Lightweight Solution

In modern industrial infrastructure, FRP micro mesh grating is fast becoming the preferred solution for platforms, walkways, and corrosion-prone environments. Its outstanding anti-slip, anti-corrosive, and lightweight attributes position it at the center of the worldwide shift toward safer, more sustainable, and maintenance-friendly grating systems. This in-depth guide covers industry trends, technical data, application scenarios, technology advantages, manufacturer comparison, and the most up-to-date custom project solutions.

1. FRP Grating Industry Trends and Market Overview

According to Market Research Future, the global FRP (Fiber Reinforced Plastic) grating market was valued at USD 551 million in 2023, projected to exceed USD 780 million by 2027 with a Compound Annual Growth Rate (CAGR) of 7.1%. The MarketsandMarkets 2024 analysis also confirms the increased adoption of micro mesh variants in petrochemical, water treatment, and marine sectors, driven by stringent safety regulations and the need for advanced anti-slip solutions.

- Shift from traditional steel/aluminum grating to FRP due to lower maintenance and higher durability.

- Rise in demand for micro mesh (small aperture FRP micro mesh grating of 12.7×12.7mm) for anti-drop and high-safety applications.

- Asia-Pacific regions contribute over 40% to market growth, led by expansion of water/wastewater and chemical industries.

2. FRP Micro Mesh Grating – Technical Parameters & Specifications

| Parameter | Typical Value/Range | Standard/Reference |

|---|---|---|

| Mesh Size | 12.7 × 12.7 mm (½” × ½”) | ANSI/NAAMM MBG 531-14 |

| Panel Thickness | 13, 25, 30, 38mm | ASTM E84 |

| Resin Type | Isophthalic Polyester, Vinyl Ester, Phenolic | ISO 9001:2015, ISO 178 |

| Bearing Bar Size | 3–5mm (micro mesh), up to 7mm (platform) | ASTM D792 |

| Open Area | ~42–55% | - |

| Slip Resistance | Coarse-grit surface, R13 (DIN 51130) | ASTM C1028 |

| Ultimate Load (KN/m²) | ≥ 250 (micro mesh) | EN 13706 |

| Fire Rating | Class 1 (≤25, ASTM E84) | UL 94V-0 |

| Standard Panel Size | 1220×3660mm, 1000×4000mm | Custom available |

| Weight | 7–12kg/m² | ASTM D2584 |

3. Manufacturing Process Flow of FRP Micro Mesh Grating

- High-quality E-glass roving

- Thermoset resins: isophthalic/vinyl ester

- Pigments & additives

- Molded: Layered insertion of glass + resin in steel mold

- Pultruded: CNC alignment of profiles

- Thermal curing (90-140℃, 60–90min)

- Automated resin cross-linking

- Demolded for inspection

- CNC cutting for custom sizing

- Addition of anti-slip silica grit

- Load & fire resistance tests

- Visual/Dimensional inspection

- Barcode traceability & packaging

* Leading suppliers like ZJComposites leverage CNC laser trimming for ultra-precise micro mesh tolerances.

Material Highlights & Quality Standards

- Materials: E-glass fiber and premium, UV-resistant thermoset resins (Isophthalic/Vinyl Ester/Phenolic base).

- Manufacture: High-temperature molded process or fully continuous pultrusion lines. Uses automated CNC trimming for tolerance ≤1.2mm — ideal for tight micro mesh requirements.

- Certification: All grating products pass ISO 9001, ASTM E84, EN 13706 certification; fire rating up to Class 1.

- Life Span: 25–50 years corrosion-free in aggressive chemical and marine environments (based on 2023 LABSALT® data and field inspection in Chinese refineries).

Compared to stainless steel, FRP micro mesh grating delivers up to 80% weight reduction and fivefold longer life in corrosive media, according to CompositesWorld’s Industry Report.

4. Product Spotlight: Holiday Special Offers GRP FRP Gratings Fiberglass Grates

- Panel Size: 1220x3660mm, 38mm thick (custom sizes up to 4000mm length)

- Micro Mesh: 12.7mn × 12.7mm (½” × ½”) grid for anti-slip and small-object blockage

- Surface: Heavy-duty silica grit, R13 anti-slip index

- Structural Load: ≥ 250KN/m² (Test according to EN13706:2002)

- Corrosion Resistance: Passes ASTM D543 chemical test; no structural change after 1000h brine or acid soak.

- Certifications: ISO 9001:2015, EN 13706-1, ASTM E84, UL94V-0

- Warranty: 15 Years Limited with ZJComposites' Customer Support (Contact Support)

Key Product Data (Visualized)

Pie Chart: Application Distribution (2023, Global Market)

Service Life vs. Maintenance Comparison (Lab Test, 2024)

5. Manufacturer Comparison: FRP Micro Mesh Grating, FRP Platform Grating, FRP Protruded Grating

| Brand | Product Type | CNC Processing | Certification | Main Markets | Project Reference | Warranty/Support |

|---|---|---|---|---|---|---|

| ZJComposites | FRP micro mesh grating, platform, protruded, custom | Advanced (±1.2mm tolerance) | ISO 9001, EN 13706, ASTM, UL | Asia, North America, EU, MENA | PetroChina, Shell, TaTa Steel | 15 Years, 24/7 service |

| Fibergrate | Molded, pultruded, micro mesh | Advanced | ISO 9001, ASTM | USA/EU, Mideast | BASF, Emirates Steel | 10 Years, project support |

| Strongwell | Pultruded FRP, platform | Standard | ISO, EN/CE | Global | ExxonMobil, Boeing | 10 Years basic |

| Sino GRP | Platform, trench, structural | Standard | ISO 9001, GB/T | China/Asia | Minmetals, Sinopec | 10 Years |

6. Application Scenarios: Micro Mesh & Platform Gratings

- Chemical Plants: High anti-slip, chemical-resistant frp micro mesh grating covers walkways, platforms & drainage covers for acid/alkaline environments.

- Wastewater Treatment: Micro mesh (frp platform grating) prevents equipment/tool drop-through; meets FDA slip safety standards.

- Marine & Offshore: Used as landing nets, shipboard flooring—unaffected by seawater or salt fog.

- Metallurgy: Platform/access platforms in blast furnaces, offering 40–80% weight saving vs. steel, simplifying maintenance.

- Oil & Gas: Explosion-proof, Class 1 fire rating (ASTM E84), installed offshore & refinery skids.

- Municipal Construction: Waterproof pedestrian bridges, water pump covers, subway maintenance, UV-resistant for >20 years outdoors.

Feedback from ZJComposites clients indicates rapid installation, zero welds, and high load sustainability are key advantages in harsh or dynamic work environments.

7. Custom Solutions & Project Delivery

- Custom Aperture/Thickness: CNC cut-outs, special micro mesh configs (down to 6mm), heavy-duty load grids.

- Surface Choice: Standard, coarse grit, or concave anti-slip; logo marking service for asset traceability.

- Color Coding: UV-resistant pigments (gray, green, yellow) as per project standards.

- Delivery Time: Standard stock (3–7 days); custom sizes/processes (10–17 days ex-works), DDP global available.

- Quality Guarantee: 15 years limited warranty (ISO-certified production, 100% load test on each panel).

- Technical Support: Project-based engineering, CAD layout, on-site installation, and remote guidance.

Sample Project Timetable (Custom FRP Protruded Grating)

| Stage | Duration | Details |

|---|---|---|

| Design/Drawings | 2–4 days | AutoCAD/3D modeling, approval |

| Raw Material Prep | 2–3 days | Cutting, resin batching |

| Molding/Curing | 3–5 days | CNC lay-up, automated molding |

| Finishing/QA | 2 days | Grit layer, dimensional inspection |

| Packing/Shipping | 1–3 days | Traceable, seaworthy packout |

8. Application Case Study: FRP Micro Mesh Grating in Practice

Project: Platform Walkways in Wastewater Treatment Facility, Singapore (2023)- Scope: 1560m² of FRP micro mesh grating for tank-top platforms, pipelines, and sump covers

- Application: Required 12.7mm mesh aperture (anti-tool drop), concave anti-slip, and edge banding

- Performance: Zero corrosion/repair in one year, 9% increase in operational safety

- Client Feedback: “Installation completed 30% faster than steel. Maintenance practically eliminated. All platform gratings certified to EN 13706 standard.” — Facility Manager, SembCorp

The project also demonstrated a 92% reduction in surface maintenance labor, supporting claims made by major industry reviews (CompositesWorld 2023 Analysis).

9. Professional FAQ for FRP Micro Mesh Grating & Related Terms

10. Support & Trust: Delivery, Warranty and After-Sales Service

- Delivery: Standard: 4–7 days (stock); Custom: 10–17 days; DDP support globally via main ports

- Warranty: 15 years, product replacement/repair guarantee (certificate by ZJComposites)

- Certification: Full ISO/EN/ASTM batch certification, each order traceable by lot number

- Online/Phone Support: 24/7 technical response (+86 572 83297239) or Email

- Installation Guidance: Project CAD, manual/video, and on-site technical support for complex projects

11. References & Further Reading

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025