loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

јан . 09, 2025 13:58

Back to list

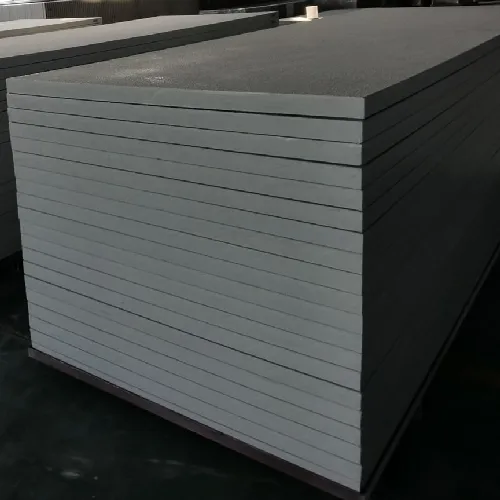

frp grating panels

FRP grating panels have become indispensable in numerous industries due to their exceptional properties and versatility. Unlike traditional materials such as steel or wood, FRP (Fiberglass Reinforced Plastic) offers a lightweight yet robust alternative that caters to a wide array of applications. Companies looking to invest in reliable, durable, and cost-effective solutions are increasingly gravitating toward these innovative panels.

The safety benefits associated with FRP grating panels are also noteworthy. Their anti-slip surface significantly reduces the risk of accidents in wet or oily conditions, a feature highly valued in industries such as manufacturing and oil and gas. Additionally, the fire-retardant properties of specific FRP formulations provide an added layer of protection, ensuring compliance with safety regulations without compromising on performance. When assessing the cost implications, potential buyers might initially perceive FRP grating panels as a more expensive option compared to traditional materials. However, their durability, resistance to wear and tear, and low maintenance needs often lead to lower life-cycle costs. Businesses leveraging FRP solutions typically experience noticeable returns on investment, stemming from decreased repair expenses and extended intervals between replacements. For professionals considering FRP grating panels, networking with industries that have integrated these materials into their infrastructure can provide valuable insights. Understanding real-world applications and outcomes enhances decision-making processes and bolsters trust in the product’s capabilities. Consulting with experienced providers who specialize in FRP can also ensure that the chosen solution is tailored to meet the specific demands of your project, further optimizing results. In conclusion, FRP grating panels present a compelling case for industries seeking a resilient, adaptable, and economically viable solution. From diverse application capabilities to significant sustainability credentials, these panels are redefining material standards across critical sectors. Embracing FRP technology not only enhances operational efficiency but also underscores a commitment to innovation and sustainability.

The safety benefits associated with FRP grating panels are also noteworthy. Their anti-slip surface significantly reduces the risk of accidents in wet or oily conditions, a feature highly valued in industries such as manufacturing and oil and gas. Additionally, the fire-retardant properties of specific FRP formulations provide an added layer of protection, ensuring compliance with safety regulations without compromising on performance. When assessing the cost implications, potential buyers might initially perceive FRP grating panels as a more expensive option compared to traditional materials. However, their durability, resistance to wear and tear, and low maintenance needs often lead to lower life-cycle costs. Businesses leveraging FRP solutions typically experience noticeable returns on investment, stemming from decreased repair expenses and extended intervals between replacements. For professionals considering FRP grating panels, networking with industries that have integrated these materials into their infrastructure can provide valuable insights. Understanding real-world applications and outcomes enhances decision-making processes and bolsters trust in the product’s capabilities. Consulting with experienced providers who specialize in FRP can also ensure that the chosen solution is tailored to meet the specific demands of your project, further optimizing results. In conclusion, FRP grating panels present a compelling case for industries seeking a resilient, adaptable, and economically viable solution. From diverse application capabilities to significant sustainability credentials, these panels are redefining material standards across critical sectors. Embracing FRP technology not only enhances operational efficiency but also underscores a commitment to innovation and sustainability.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025