loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

јан . 10, 2025 08:51

Back to list

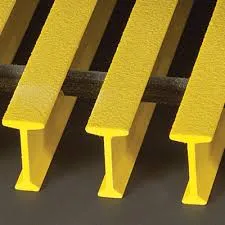

frp grating installation

FRP (Fiberglass Reinforced Plastic) gratings have become increasingly popular in various industries due to their lightweight, durable, and corrosion-resistant properties. However, the installation process of FRP gratings requires careful consideration to ensure the product's longevity and effectiveness. Drawing from extensive experience and industry expertise, here are the essential steps and insights for a successful FRP grating installation.

The layout of the FRP gratings should be designed in a manner that aligns with the structure's load-bearing capabilities. During installation, securely fasten the gratings to the support structure using high-quality, corrosion-resistant fasteners. Stainless steel fasteners are often recommended due to their superior strength and resistance to environmental factors. Attention to detail during the installation process cannot be overstated. Ensure that all gratings are level, and there are no uneven surfaces or gaps which might compromise safety or performance. It is also essential to inspect all fasteners to confirm that they are tightened according to specifications and are in optimal working condition. Post-installation care is also crucial for maintaining the integrity of the FRP gratings. Regular inspections should be scheduled to check for wear and tear, particularly in high-traffic areas. Any damage should be promptly addressed to prevent further deterioration. Cleaning the gratings with appropriate solutions will preserve their appearance and functionality over time. In conclusion, a successful FRP grating installation hinges on meticulous planning, the use of proper tools and materials, and ongoing maintenance. These practices are supported by a wealth of industry expertise and can significantly enhance the safety and durability of the installed product. Remember, a well-executed installation not only leverages the superior qualities of FRP gratings but also instills confidence in their longevity and dependability.

The layout of the FRP gratings should be designed in a manner that aligns with the structure's load-bearing capabilities. During installation, securely fasten the gratings to the support structure using high-quality, corrosion-resistant fasteners. Stainless steel fasteners are often recommended due to their superior strength and resistance to environmental factors. Attention to detail during the installation process cannot be overstated. Ensure that all gratings are level, and there are no uneven surfaces or gaps which might compromise safety or performance. It is also essential to inspect all fasteners to confirm that they are tightened according to specifications and are in optimal working condition. Post-installation care is also crucial for maintaining the integrity of the FRP gratings. Regular inspections should be scheduled to check for wear and tear, particularly in high-traffic areas. Any damage should be promptly addressed to prevent further deterioration. Cleaning the gratings with appropriate solutions will preserve their appearance and functionality over time. In conclusion, a successful FRP grating installation hinges on meticulous planning, the use of proper tools and materials, and ongoing maintenance. These practices are supported by a wealth of industry expertise and can significantly enhance the safety and durability of the installed product. Remember, a well-executed installation not only leverages the superior qualities of FRP gratings but also instills confidence in their longevity and dependability.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025