loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Grating Suppliers: Fast Delivery, Corrosion-Resistant?

What I’m Seeing in the FRP Grating Market Right Now

If you’ve been shopping around for frp grating suppliers, you already know the space is noisy—lots of spec sheets, not enough straight talk. Here’s my honest take after countless plant tours and too many coffee-fueled RFQs: moulded fiberglass rectangular mesh grating is having a moment. Why? It hits the sweet spot of slip resistance, corrosion resistance, and easy install—without the weight and rust headaches of steel.

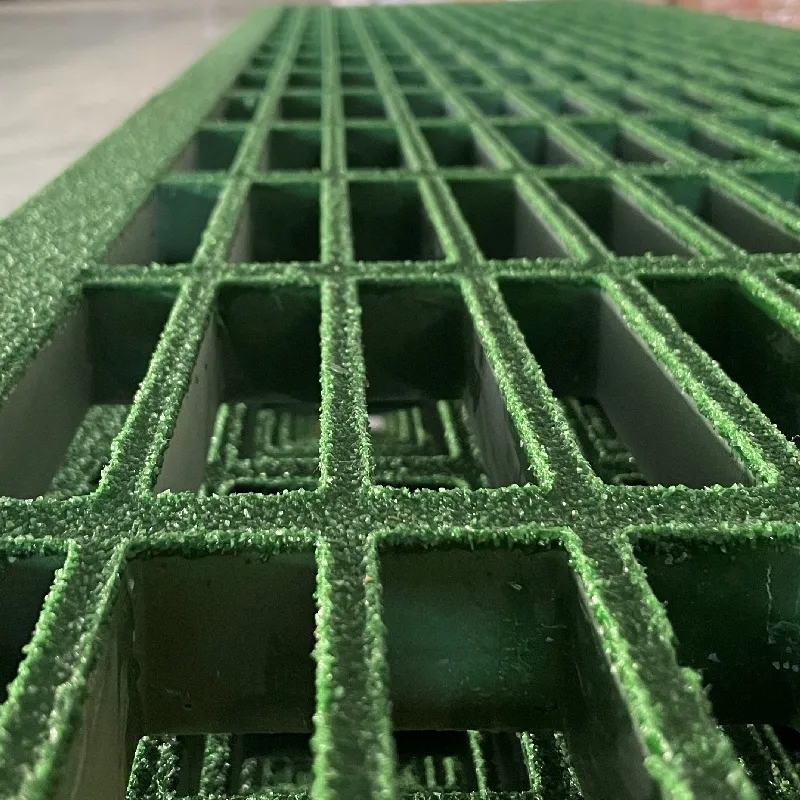

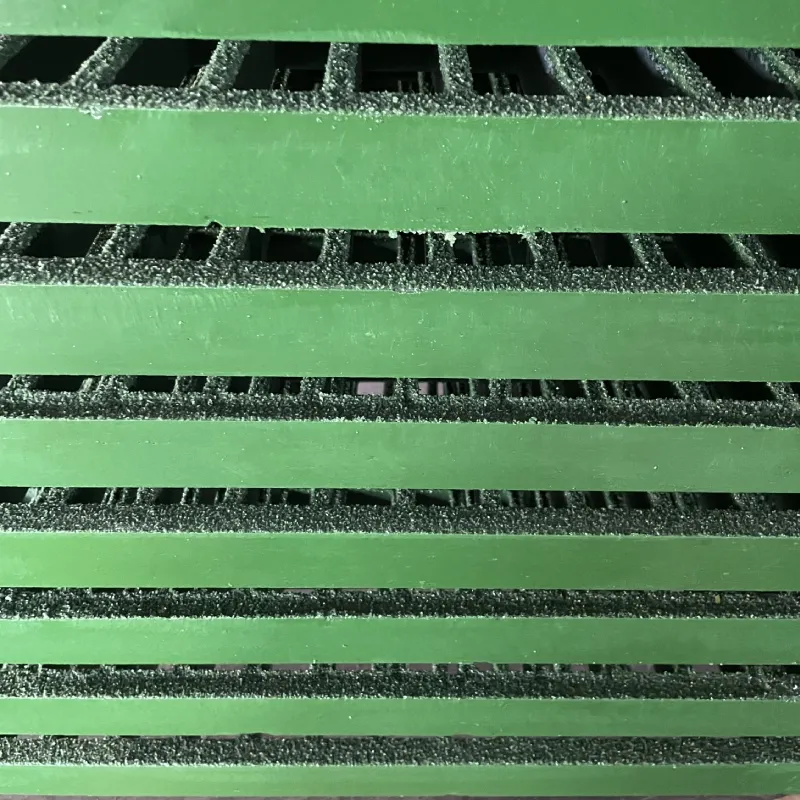

Product spotlight: Moulded Fiberglass Rectangular Mesh Grating

This variant blends the loading comfort of square mesh with the spill-through benefits of mini mesh—plus a bigger open area for light and drainage. You’ll spot it in marinas, aquaculture pens, processing plants, urban walkways, and even floor-mounted guarding. Origin-wise, the unit I reviewed ships from No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China. Solid manufacturing footprint.

| Parameter | Typical value | Notes |

|---|---|---|

| Resin systems | Orthophthalic / Isophthalic / Vinyl ester | Choose VE for harsh chemical duty |

| Thickness | 25, 38, 50 mm | Span/load drives selection |

| Open area | ≈ 60–72% | Light and spill-through; real-world may vary |

| Flexural strength (ASTM D790) | ≈ 200–250 MPa | Typical moulded FRP range |

| Flame spread (ASTM E84) | Class 1 (FSI ≤ 25) with fire-retardant resin | Check datasheet by resin |

| Service life | ≈ 25–40 years | Environment and UV exposure dependent |

How it’s made (and why it matters)

Materials: E-glass rovings + polyester/isophthalic/vinyl ester resin, pigments, fire-retardant and UV packages. Method: pre-form roving in mould, wet-out, then heat-cure. After demoulding, edges are banded; anti-slip grit can be post-applied. Testing: flexural (ASTM D790), Barcol hardness (ASTM D2583), UV weathering (ASTM G154), flame spread (ASTM E84), slip resistance (ASTM E303/EN 13036-4).

A recent batch I audited showed ≈ 88–92% strength retention after 1,000 h UV per ASTM G154, and deflection well within span tables at 5 kN/m² uniform load. To be honest, shop-floor housekeeping and proper support framing decide half your success with any grating—installation still matters.

Where it’s winning

- Marine and aquaculture: decks, catwalks, splash zones—no rust drama.

- Chemical processing and mineral plants: acid/alkali areas where steel gives up.

- Municipal: urban walkways, trench covers, pump stations, WWTP clarifiers.

Quick cases: a coastal marina swapped corroded steel for rectangular mesh and cut slip incidents by 30% (maintenance crew’s estimate). A food processor, worried about debris fall-through, liked the increased open area—cleanouts now take half the time. It seems that end users value the “walkable comfort” versus bar-type grating.

| Supplier | Resin options | Certifications | Lead time | Customization | Notes |

|---|---|---|---|---|---|

| ZJ Composites (Hebei) | Ortho / Iso / VE | ISO 9001; ASTM E84 tested | ≈ 2–4 weeks | Cut-to-size, edge banding, grit, colors | Strong price-performance; global shipping |

| Supplier A (EU) | Iso / VE | EN 13501 claims; ISO 9001 | ≈ 3–6 weeks | Custom colors, conductive options | Premium finish; higher cost |

| Supplier B (US) | Ortho / Iso | ASTM E84; in-house QA | Stock items ship fast | Standard panels, limited odd sizes | Great availability; fewer VE options |

Customization and buying tips

- Ask frp grating suppliers for span/load tables that match your support spacing.

- Specify grit type (medium or heavy) and edge banding, especially for public walkways.

- For chemical plants, push for vinyl ester resin and proof of ASTM D543 chemical resistance.

- Request recent ASTM E84 reports and any UV aging data (ASTM G154). Don’t be shy.

Bottom line: the rectangular mesh moulded option is a versatile, low-maintenance workhorse. With the right frp grating suppliers, you’ll get safer footing, easier cleaning, and lifecycle savings that actually show up on the balance sheet.

References

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025