loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Comparative Analysis of FRP Rod Pricing in the Market Today

Understanding the Pricing of FRP Rods An In-Depth Analysis

Fiber Reinforced Polymer (FRP) rods have gained significant popularity in various applications due to their superior strength, lightweight properties, and resistance to corrosion. Their use spans across construction, civil engineering, and manufacturing industries, where they often serve as reinforcement materials, tension cables, and structural supports. However, the price of FRP rods can vary widely based on several factors, including material composition, manufacturing process, and market demand. This article aims to explore the key elements that influence the pricing of FRP rods and provide insights for potential buyers and industry stakeholders.

Composition and Material Types

FRP rods are typically made from materials such as glass fiber, carbon fiber, or aramid fiber, each offering distinct mechanical properties and performance characteristics. Glass fiber rods are the most common due to their affordability and adequate strength for many applications, making them a popular choice for a variety of construction projects. Conversely, carbon fiber rods are more expensive but provide superior strength-to-weight ratios and higher resistance to fatigue, making them suitable for high-performance applications in aerospace and high-stress environments. The price of FRP rods will vary significantly based on the type of fiber used, with carbon fiber products typically costing more than their glass fiber counterparts.

Manufacturing Processes

The method used to manufacture FRP rods can also influence their price. Common manufacturing techniques include pultrusion, filament winding, and hand lay-up. Pultrusion is a continuous process that produces consistent quality and strength, making it a cost-effective option for mass production of FRP rods. However, it may involve higher initial capital investment for machinery. Filament winding, while allowing for greater design flexibility and enhanced mechanical properties, can be more labor-intensive and costly. Hand lay-up, though more versatile for custom projects, is the least efficient and often results in higher unit costs. Understanding these processes is crucial for buyers, as the manufacturing method directly impacts both the quality and pricing of the final product.

Market Demand and Supply Chain Dynamics

frp rod price

Like any commodity, the price of FRP rods is also influenced by market demand and supply chain dynamics. The construction industry experiences cyclical demand based on economic conditions, government infrastructure projects, and advancements in technology. During periods of high construction activity, the demand for FRP rods may surge, leading to increased prices. Additionally, global trade conditions, freight costs, and raw material availability can all affect the pricing landscape. For instance, fluctuations in the price of resin or raw fibers used to produce FRP rods can lead to changes in manufacturing costs and, consequently, the market price.

Customization and Specialized Applications

Another determinant of FRP rod pricing is the level of customization required. Standard FRP rods are cost-effective, but tailored solutions for specific applications—such as rods designed to withstand extreme environmental conditions or those with enhanced electrical insulating properties—can carry a premium price. Customization often involves specialized engineering and additional testing, leading to increased production costs that are passed on to the consumer. For buyers, it is essential to weigh the benefits of customized solutions against their costs and consider how they align with project requirements.

Future Trends and Sustainability Concerns

As the world shifts towards more sustainable building practices, the demand for eco-friendly materials is rising. Developers and builders increasingly prioritize materials that not only meet high performance criteria but also have minimal environmental impact. Manufacturers responding to this trend may invest in more sustainable production methods or bio-based FRP materials, which could affect pricing structures. As consumer awareness of sustainability grows, the cost of traditional FRP rods may be reassessed in light of their environmental impact versus newer, greener alternatives.

Conclusion

The pricing of FRP rods is a multifaceted issue influenced by material composition, manufacturing processes, market dynamics, customization, and sustainability considerations. For industry professionals and consumers, understanding these factors is crucial when selecting the right FRP rod for their needs. As the market continues to evolve, keeping abreast of trends and changes will empower buyers to make informed decisions, ultimately leading to better project outcomes and potentially lower costs in their supply chain management. Whether for construction, manufacturing, or any other application, the choice of FRP rods should be aligned with both performance requirements and budgetary considerations to achieve optimal results.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

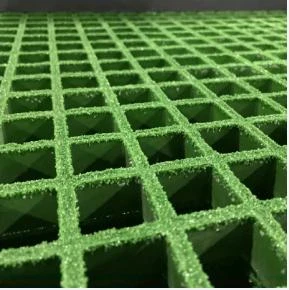

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025