loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Solutions for FRP Molded Gratings in Diverse Applications

The Advantages and Applications of FRP Moulded Gratings

FRP (Fiberglass Reinforced Plastic) moulded gratings have gained significant popularity in various industries due to their unique properties and advantages. These composite materials combine the strength of fiberglass with the durability of plastic, creating a versatile product that meets the demands of modern construction and engineering applications. This article will explore the various benefits of FRP moulded gratings and their wide-ranging applications.

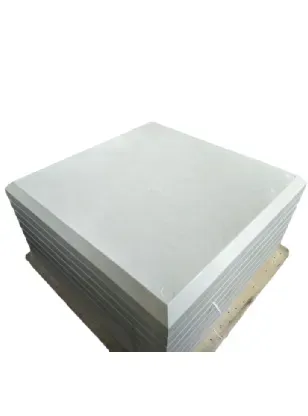

What Are FRP Moulded Gratings?

FRP moulded gratings are structural components made from a polymer matrix reinforced with fiberglass. The manufacturing process involves combining resin with chopped fiberglass, which is then molded into a grid-like structure. This results in a product that is lightweight yet incredibly strong, making it suitable for a variety of structural applications. FRP gratings are available in various sizes, colors, and styles, allowing for customization to meet specific project needs.

Advantages of FRP Moulded Gratings

1. Corrosion Resistance One of the most significant advantages of FRP moulded gratings is their resistance to corrosion. Unlike traditional materials such as steel and aluminum, FRP does not rust, making it an ideal choice for environments exposed to chemicals, moisture, and other corrosive agents. This property ensures a longer lifespan and reduces maintenance costs.

2. Lightweight FRP moulded gratings are significantly lighter than steel or aluminum alternatives, which simplifies installation and reduces labor costs. Their lightweight nature also allows for easier handling and mobility on job sites, making it easier to transport and install.

3. High Load-Bearing Capacity Despite being lightweight, FRP grating offers high tensile strength and load-bearing capacity. This makes it suitable for heavy-duty applications in various industries, including petrochemical, marine, and wastewater treatment.

4. Slip Resistance Safety is a primary concern in industrial settings, and FRP moulded gratings offer exceptional slip resistance. The surface can be designed with a textured finish or anti-slip properties, providing secure footing and minimizing the risk of accidents.

5. Fire Resistance Many FRP gratings are manufactured with fire-resistant properties, making them suitable for environments where fire safety is a concern. This characteristic is essential in facilities dealing with flammable materials.

frp moulded gratings

6. UV Resistance Exposure to sunlight can degrade many materials over time. However, FRP gratings are designed to withstand UV radiation, ensuring they maintain their structural integrity and appearance even in outdoor applications.

7. Ease of Maintenance FRP products require minimal maintenance compared to traditional materials. Their resistance to corrosion and environmental factors means they do not need regular inspections for rust or degradation.

Applications of FRP Moulded Gratings

The versatility of FRP moulded gratings makes them suitable for numerous applications across different industries

- Industrial Flooring In factories and processing plants, FRP gratings provide durable flooring options that can withstand heavy traffic while resisting chemical exposure.

- Walkways and Platforms Many outdoor walkways and platforms use FRP gratings for pedestrian access due to their lightweight and slip-resistant properties.

- Marine Applications FRP is widely used in shipbuilding and offshore structures due to its exceptional corrosion resistance, making it ideal for marine environments.

- Wastewater Treatment Plants FRP gratings are often used in wastewater treatment facilities where exposure to harsh chemicals and corrosive substances is a concern.

- Electrical Applications Non-conductive FRP gratings are also used in electrical facilities, ensuring safety in environments where electrical hazards may arise.

In conclusion, FRP moulded gratings offer a blend of lightweight design, high strength, and exceptional resistance to various environmental factors. Their diverse range of applications makes them an essential choice for modern engineering and construction projects. As industries continue to seek innovative materials that enhance safety and efficiency, FRP gratings remain at the forefront of composite material technology.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025