loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Shk . 18, 2025 00:59

Back to list

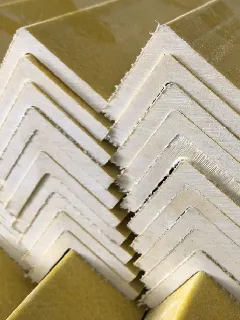

Anti- Corrosion Cost Effective FRP Pultrusion Grating

Navigating the expansive world of industrial materials, fiberglass pultruded grating is often overlooked yet is an integral component in various sectors such as marine, chemical processing, and construction. Its unique combination of strength, durability, and versatility makes it an undeniable asset in environments challenged by corrosive elements. For those who rely on resilient materials, understanding the definitive qualities of fiberglass pultruded grating is paramount.

From a safety perspective, it's imperative to consider the slip-resistant nature of fiberglass pultruded grating. Given its superior traction properties, industries prioritize its use to mitigate the risk of slips and falls, which are leading causes of workplace accidents. With customized surfaces available to suit specific needs, each installation can be optimized for maximum worker safety. Equally important is the customization capability of fiberglass pultruded grating. Depending on specific application requirements, it can be tailored in a variety of panel sizes, thicknesses, and colors, providing not only functional utility but also aesthetic flexibility. This adaptability extends to chemical resistance as well, with the resin matrix formulated to withstand specific chemical exposures, further ensuring the material's suitability across diverse industrial applications. Environmentally conscious organizations will find an added benefit in fiberglass pultruded grating’s low environmental impact. Its long lifespan and minimal need for chemical treatments contribute to a reduced ecological footprint, aligning with global efforts towards sustainable industrial practices. Experts and industry leaders increasingly acknowledge fiberglass pultruded grating as a top-tier solution that addresses both current challenges and anticipates future demands. It is not just a material choice but a commitment to enduring quality and safety. As industries grow and require more advanced solutions, fiberglass pultruded grating offers the promise of innovation coupled with proven dependability. For businesses considering an upgrade or a new installation, consulting with professionals who specialize in this field ensures an optimized solution that takes advantage of the latest developments in material science. As technology and methods continue to evolve, so too does the potential of fiberglass pultruded grating in revolutionizing how industries approach their structural challenges.

From a safety perspective, it's imperative to consider the slip-resistant nature of fiberglass pultruded grating. Given its superior traction properties, industries prioritize its use to mitigate the risk of slips and falls, which are leading causes of workplace accidents. With customized surfaces available to suit specific needs, each installation can be optimized for maximum worker safety. Equally important is the customization capability of fiberglass pultruded grating. Depending on specific application requirements, it can be tailored in a variety of panel sizes, thicknesses, and colors, providing not only functional utility but also aesthetic flexibility. This adaptability extends to chemical resistance as well, with the resin matrix formulated to withstand specific chemical exposures, further ensuring the material's suitability across diverse industrial applications. Environmentally conscious organizations will find an added benefit in fiberglass pultruded grating’s low environmental impact. Its long lifespan and minimal need for chemical treatments contribute to a reduced ecological footprint, aligning with global efforts towards sustainable industrial practices. Experts and industry leaders increasingly acknowledge fiberglass pultruded grating as a top-tier solution that addresses both current challenges and anticipates future demands. It is not just a material choice but a commitment to enduring quality and safety. As industries grow and require more advanced solutions, fiberglass pultruded grating offers the promise of innovation coupled with proven dependability. For businesses considering an upgrade or a new installation, consulting with professionals who specialize in this field ensures an optimized solution that takes advantage of the latest developments in material science. As technology and methods continue to evolve, so too does the potential of fiberglass pultruded grating in revolutionizing how industries approach their structural challenges.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025