loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Grating Suppliers – Durable & Lightweight Solutions

As industrial infrastructure demands rapid upgrades in durability, cost-efficiency, and corrosion resistance, FRP grating suppliers have become pivotal players. This comprehensive guide explores the market’s top suppliers, their technological prowess, and focuses on Moulded Fiberglass Rectangular Mesh Grating, discussing its manufacturing process, material science, compliance with leading standards, and why it’s preferred in industries like petrochemical, metallurgy, and water treatment.

I. Market Overview: The Global Landscape of FRP Grating Suppliers

According to MarketsAndMarkets, the global FRP grating market size is projected to reach USD 890 million by 2027—mainly driven by heightened demand in infrastructure, oil & gas, marine, and environmental engineering. Leading frp grating suppliers focus on innovation, custom engineering, and compliance to standards like ISO and ANSI to secure market share.

| Supplier | Headquarters | Core Product | Standard Compliance | Annual Output (Tons) | Certifications | Typical Applications |

|---|---|---|---|---|---|---|

| ZJ Composites | China | Moulded GRP/FRP Grating | ISO 9001, ASTM E-84, EN13706 | 13,000+ | SGS, ABS, DNV | Chemical, Offshore, Wastewater |

| Fibergrate | USA | Moulded & Pultruded FRP | ANSI, OSHA, ISO | 11,500+ | Bureau Veritas, UL | Oil & Gas, Food Processing |

| Strongwell | USA | Pultruded FRP Structures | ASTM, ISO | 7,800+ | UL, ISO 14001 | Power, Marine |

| Techno Composites | Germany | Moulded Grating | EN 13706, DIN | 6,000+ | ISO 9001 | Rail, HVAC |

The competitive advantage in this sector boils down to advanced composite technology, strict adherence to international standards, and project-tested product reliability. Proven suppliers like ZJ Composites distinguish themselves with extensive engineering capability and a strong after-sales network.

II. Product Focus: Technical Parameters of Moulded Fiberglass Rectangular Mesh Grating

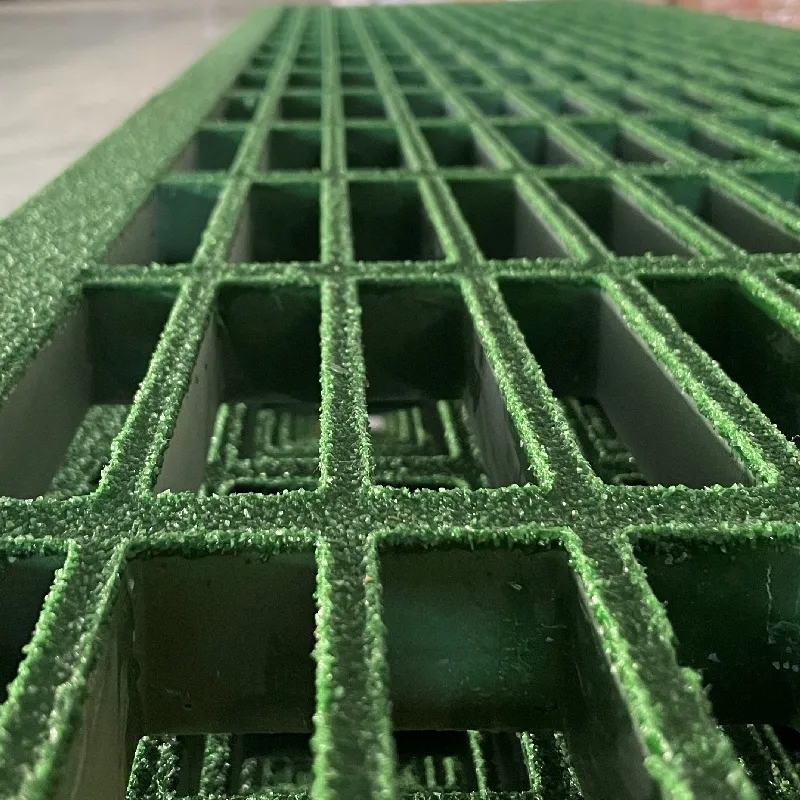

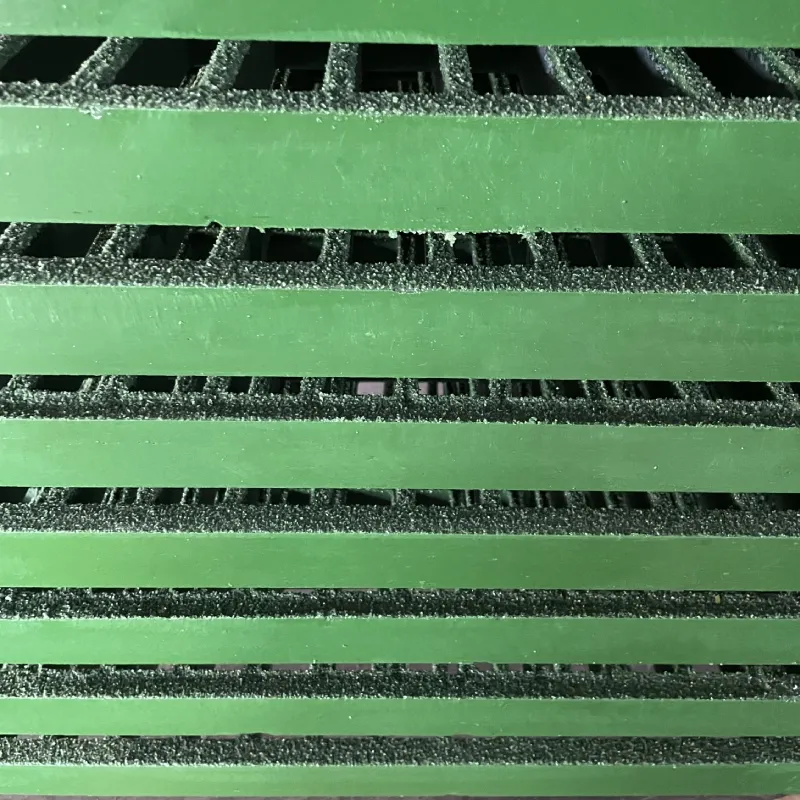

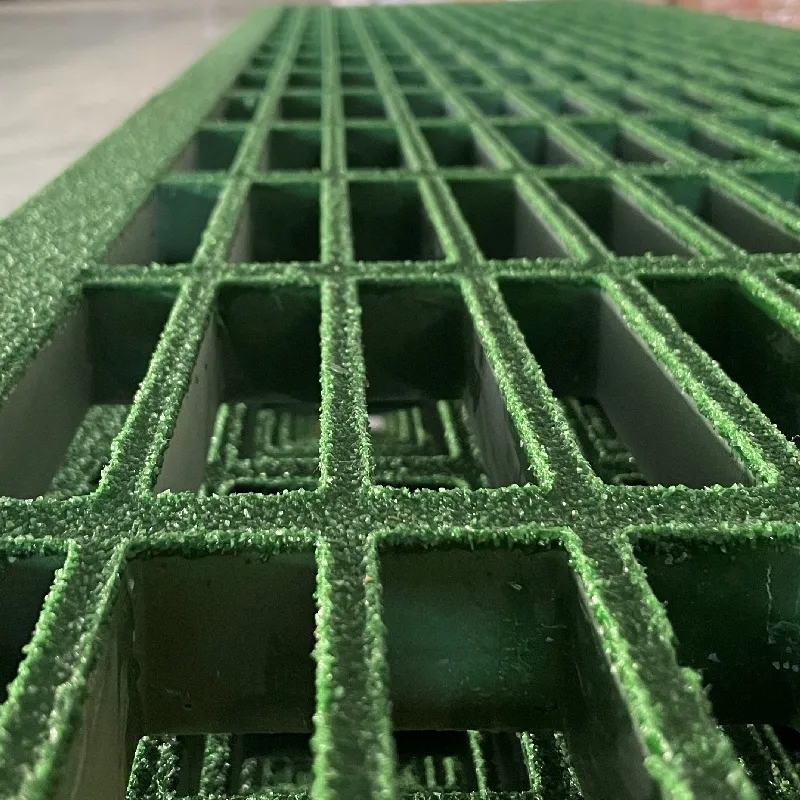

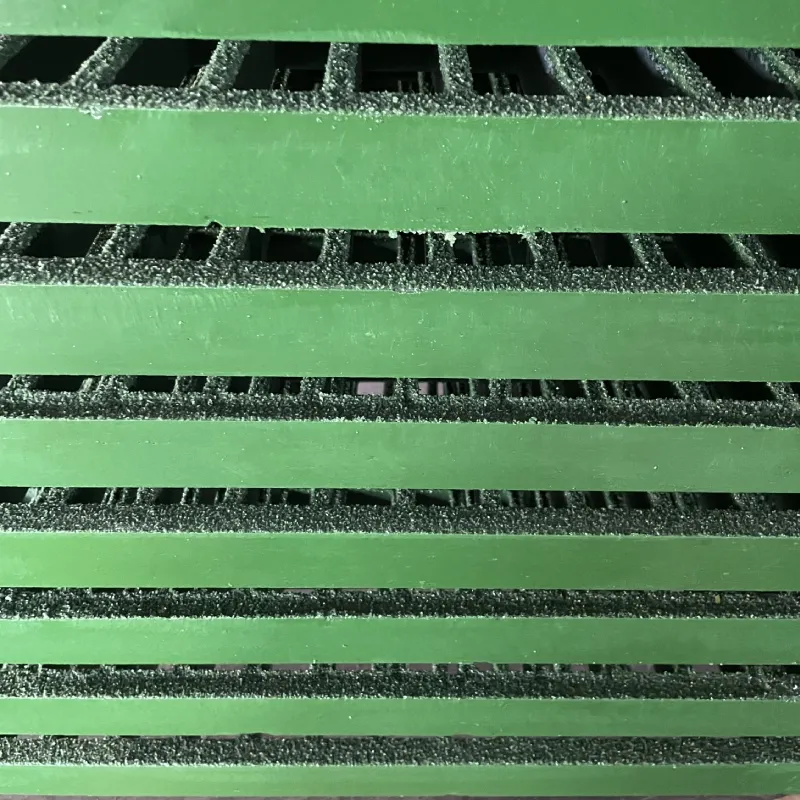

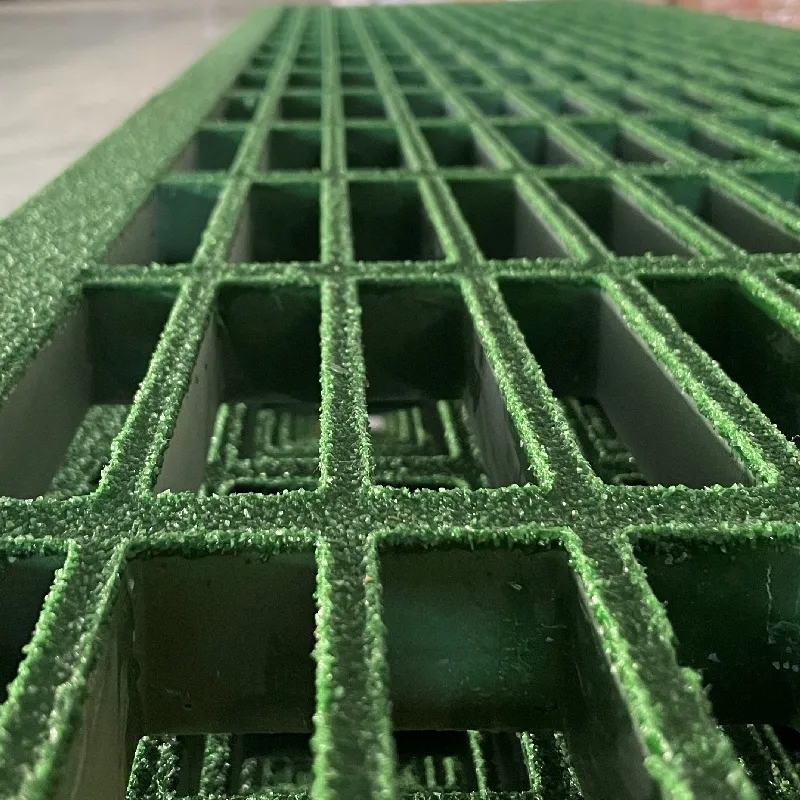

The Moulded Fiberglass Rectangular Mesh Grating is an engineered composite panel made via resin matrix moulding and E-glass fiber reinforcement.

Key Technical Features:

- Material: High-quality E-glass fiber, premium unsaturated polyester/vinyl ester resin

- Open Rate: 68% standard (customizable 60-75%)

- Standard Mesh: 38x38mm, 40x13mm; other mesh sizes available

- Thickness: 25mm, 30mm, 38mm (up to 50mm on request)

- Load Bearing: ≥8000N/m2 (ASTM E-119, EN13706 certified)

- Fire Retardance: UL94 V-0 (ASTM E-84 tested, Flame spread index < 25)

- Chemical Resistance: Excellent (Resistant to Cl-, H2SO4, NaOH, etc.)

- Service Life: 25-35 years (Tested by simulated salt fog, UV aging)

III. Manufacturing Process: How Leading FRP Grating Suppliers Guarantee Quality

The advanced production line for moulded fiberglass rectangular mesh grating ensures consistency and efficiency. See the illustrated process below for clarity:

- Resin Selection: High-grade, UV-stabilized polyester or vinyl ester for tailored chemical resistance.

- Molding Precision: GRP structure molded under computer-controlled temperature/humidity for uniformity.

- Inspection & Testing: Each panel tested per EN13706/ASTM E-119, fire-retardancy & load-load deflection checks.

IV. Advantages: Why Choose FRP Grating Suppliers for Industrial Needs?

- Corrosion Resistance: Unlike steel, FRP needs no extra coating—even under H2SO4, Cl2, or salt fog exposure.

- High Strength-to-Weight Ratio: E-glass reinforcement provides superior load compared to aluminum and even some types of stainless steel at a fraction of the weight.

- Non-Slip Surface: Gritted surfaces or custom anti-skid finishes provide unmatched worker safety in wet/oily environments.

- Electrically Non-Conductive: Ideal for power substations and chemical handling zones.

- Low Maintenance: Requires minimal cleaning; lower whole-life cost compared to steel grating.

- Third-Party Tested: SGS, DNV, ABS certified, with product traceability for projects requiring strong certification documentation.

V. Supplier Comparison: Cost, Customization & Standard Compliance

| Criteria | ZJ Composites | Strongwell | Fibergrate |

|---|---|---|---|

| Customization Options | Mesh size, resin type, thickness, shape cut | Thickness, resin, limited mesh | Standard panel sizes & resin colors |

| Fire Resistance | UL94 V-0, ASTM E-84 FSI<25 | ASTM E-84 FSI < 25 | UL, ANSI |

| Lead Time | 2-3 weeks (custom), 5 days (stock) | 4-6 weeks | 3-4 weeks |

| Certifications | SGS, DNV, ISO 9001, ABS | UL, ISO | UL, Bureau Veritas |

| Warranty | 10 years | 5 years | 5 years |

What sets ZJ Composites apart among frp grating suppliers is rapid customization, comprehensive certification support, and outstanding project delivery timelines.

VI. Customization & Engineering Support from FRP Grating Suppliers

- Tailored Mesh Design: Custom panel shapes, micro-mesh, or ADA-compliant types for walkways and accessible installations.

- Resin Formulation: Isophthalic, vinyl ester, or phenolic resins fine-tuned for specific chemical environments.

- CNC Profile Cutting: Pre-cutting for quick field installation, minimizing project lead time and errors.

- Edge Treatment: Special anti-fray and color-coded safety nosing available, marked per OSHA or EN124 standard.

Leading frp grating suppliers provide full engineering support—from 3D CAD drawings to onsite measurement, ensuring panels match exact project needs.

VII. Application Scenarios: Industry-Driven Cases & Performance

FRP grating suppliers play a crucial role in industries requiring advanced material properties. Notable real-world cases include:

Requirement: Salt-fog durability, slip-safety, minimal downtime.

Result: Replaced galvanized steel grating with FRP rectangular mesh panels; corrosion loss reduced by 94.2% after 1 year.

Requirement: Strong chemical resistance (NaOH 3%), anti-slip surface for floating platforms.

Result: Tested maintenance-free for 24 months; no visual degradation detected (ISO 9227 compliance).

Requirement: Withstand 50°C, sulfuric acid mist area.

Result: Improved worker safety; surface slip resistance maintained at R12 (ISO 20345 standard).

VIII. Professional FAQ & Terminology

1. What is E-glass and why is it used in FRP grating?

E-glass (electrical glass) is a type of glass fiber known for its high tensile strength, great electrical insulation, and corrosion resistance—making it the backbone of most high-performance FRP grating.

2. What does “open rate” mean for FRP grating?

The open rate refers to the mesh’s ventilated area percentage. A 68% open rate means 68% of the panel is open, aiding drainage, airflow, and minimizing slip risks.

3. What is the significance of ASTM E-84 or EN13706 certification?

ASTM E-84 evaluates flame spread and smoke development in building materials, crucial for fire safety; EN13706 sets minimum mechanical, fire, and quality properties for structural composites in Europe—ensuring fit-for-purpose reliability.

4. What’s the difference between moulded and pultruded FRP grating?

Moulded FRP grating is produced by laying fibers in a mold and infusing resin, yielding uniform, isotropic strength; Pultruded grating is made by pulling fibers through resin baths and dies, resulting in directional strength suited for long spans.

5. How is non-slip performance achieved?

Through integrally molded grit or applied silica granules, the upper surface achieves R11~R13 slip resistance (per ISO 20345), ideal for wet and oily zones.

6. What installation standards apply?

Leading frp grating suppliers deliver predrilled panels and installation guides in line with ANSI, OSHA, EN124 guidelines—ensuring safe, efficient footing and anchoring.

7. What’s included in quality assurance and warranty?

Top suppliers (ZJ Composites, Fibergrate, etc.) offer a 10-year performance warranty with serial traceability, batch testing records, and 24/7 tech support for peace of mind.

IX. Project Delivery, Warranty, and Customer Support

- Lead Time: Rapid stock shipping (within 5 days), customized solutions in 2-3 weeks (subject to order volume).

- Warranty: 10-year full warranty; detailed quality documentation provided for each shipment.

- Customer Support: 24/7 technical consultation; multilingual support team.

- After-sales Service: Installation training, maintenance advice, global logistics support.

X. References & Industry Insights

Authoritative Quotes & Community Insights:

- “FRP grating is revolutionizing corrosion management in infrastructure projects worldwide” — CompositesWorld Journal

- "Compliance to EN13706 and ASTM E-84 is now a standard requirement in oil & gas facility upgrades, not just a bonus." — Eng-Tips FRP Forum

- “Molded FRP’s lifetime whole-life cost is 32% lower compared to traditional grating solutions” — MarketsAndMarkets FRP Grating Type Report

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025