loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

pentair frp

The Role of Pentair FRP in Modern Water Treatment Solutions

Introduction

As the world grapples with the pressing challenge of water scarcity and contamination, the quest for effective and sustainable water treatment solutions has never been more critical. Among the innovative technologies that have emerged, Fiberglass Reinforced Plastic (FRP) has gained significant traction in various applications, particularly in the water treatment sector. Pentair, a leading provider in this domain, leverages the durability, versatility, and efficiency of FRP to deliver outstanding solutions tailored to meet the complex needs of water treatment processes.

The Advantages of FRP

Fiberglass Reinforced Plastic (FRP) is a composite material made of a plastic matrix reinforced with fiberglass. This combination results in an exceptionally strong yet lightweight material that offers numerous benefits for water treatment applications. One of the most significant advantages of FRP is its resistance to corrosion, making it an ideal choice for environments exposed to harsh chemicals and varying temperatures.

Additionally, FRP is known for its strength-to-weight ratio, which makes it easier to transport and install compared to traditional materials like steel. This not only reduces the overall cost of installation but also enhances operational efficiency. Moreover, the versatility of FRP allows for various designs and configurations, enabling engineers to create customized solutions that align with specific operational requirements.

Pentair's Commitment to Quality

Pentair has established itself as a trusted name in water treatment solutions, and its commitment to quality and innovation is evident in its use of FRP technology. The company focuses on delivering products that not only meet but exceed industry standards. Pentair's FRP tanks and vessels are designed for high performance and durability, making them suitable for various applications including water filtration, chemical storage, and wastewater treatment.

To ensure the reliability and longevity of its FRP products, Pentair employs advanced manufacturing processes and rigorous quality control measures. This meticulous attention to detail guarantees that each product can withstand the demands of its intended use, ultimately resulting in less downtime and lower maintenance costs for clients.

pentair frp

Applications in Water Treatment

The applications of Pentair's FRP technology in water treatment are both diverse and impactful. In potable water systems, FRP tanks are used for filtration and disinfection processes, providing reliable barriers to contaminants. Furthermore, their lightweight nature simplifies installation, making upgrades to existing systems more feasible.

In industrial water treatment applications, the robustness of Pentair's FRP solutions allows for effective handling of aggressive chemicals and extreme operating conditions. FRP is particularly valued in environments dealing with corrosive substances, where traditional materials may fail prematurely. This reliability is critical for industries such as oil and gas, pharmaceuticals, and food processing, where water purity is paramount.

In wastewater treatment, Pentair's FRP products contribute to the efficient management of effluent processes. The adaptability of FRP allows for the design of advanced treatment systems that can be customized to meet regulatory requirements and improve recovery rates. By employing FRP technologies, municipalities and industries can reduce their environmental footprint while ensuring compliance with local and national water quality standards.

Sustainability and Future Innovations

As sustainability becomes increasingly important in the global agenda, the water treatment industry must also adapt to meet these challenges. Pentair is at the forefront of this transition, harnessing the benefits of FRP to create eco-friendly solutions that minimize resource consumption and waste. The longevity and durability of FRP products contribute to a lower overall environmental impact, aligning with modern goals of sustainability and resource conservation.

Moreover, ongoing research and development efforts by Pentair promise continued innovation in the FRP domain. New formulations and process improvements could further enhance the performance of FRP materials, making them even more effective in addressing the complexities of water treatment. The integration of smart technologies, such as IoT-enabled sensors and automation, with FRP systems is also on the horizon, paving the way for more sophisticated and efficient water treatment processes.

Conclusion

In an era where clean water is a precious commodity, Pentair's utilization of Fiberglass Reinforced Plastic (FRP) stands out as a pivotal advancement in water treatment solutions. The material's unique properties not only enhance system performance but also promote sustainability in a sector that is vital to public health and environmental protection. As Pentair continues to innovate and adapt, it plays a crucial role in shaping the future of water treatment, ensuring that communities have access to the safe and reliable water they need to thrive.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

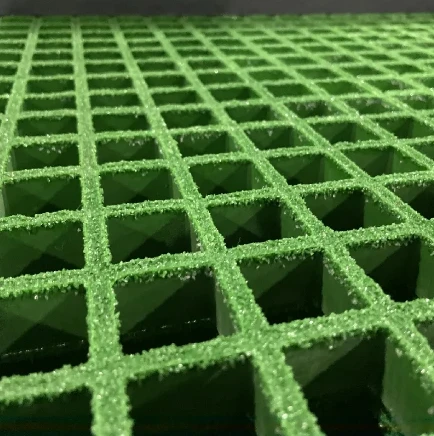

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025