loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

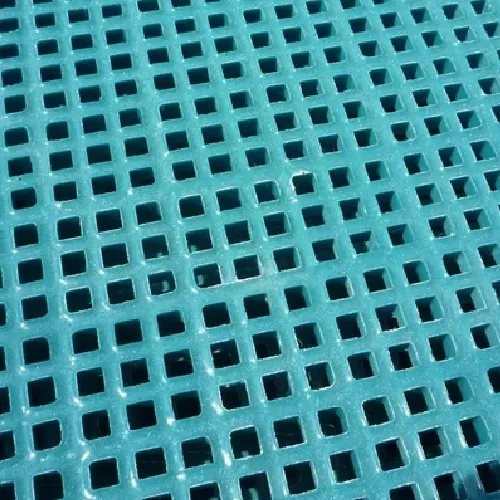

High-Strength FRP Grating for Industrial Applications and Heavy Load Support

Understanding Heavy Duty FRP Grating Applications and Advantages

In today's industrial landscape, the need for durable and efficient materials is paramount. One such material that has gained prominence in various sectors is heavy duty Fiberglass Reinforced Plastic (FRP) grating. Known for its strength, corrosion resistance, and lightweight properties, heavy duty FRP grating offers numerous benefits in a variety of applications.

What is FRP Grating?

FRP grating is a composite material made from a combination of fiberglass and resin, offering a high strength-to-weight ratio. This unique composition results in a product that not only supports heavy loads but is also resistant to various environmental factors such as chemicals, moisture, and temperature fluctuations. Heavy duty FRP grating is specifically designed to handle substantial weight and pressure, making it suitable for use in demanding environments.

Applications of Heavy Duty FRP Grating

The versatility of heavy duty FRP grating allows it to be employed in multiple industries. Here are a few key applications

1. Chemical Processing Plants Due to its excellent corrosion resistance, FRP grating is widely used in chemical manufacturing and processing facilities. It can withstand exposure to harsh chemicals and solvents, making it ideal for walkways, platforms, and drainage areas.

2. Wastewater Treatment Facilities Heavy duty FRP grating is a common choice in wastewater treatment plants where moisture and corrosive substances are prevalent. The non-slip surface also enhances safety for workers navigating these areas.

3. Oil and Gas Industry In both upstream and downstream applications, FRP grating is utilized for maintenance platforms and access ways due to its lightweight nature and ability to prevent rust, thus reducing potential hazards and maintenance costs.

4. Pharmaceuticals In environments where hygiene and cleanliness are critical, such as pharmaceutical production areas, FRP grating is often used because of its smooth surface that is easy to clean and sanitize.

heavy duty frp grating

Advantages of Heavy Duty FRP Grating

The benefits of heavy duty FRP grating extend beyond its applications. Some of its standout advantages include

- Corrosion Resistance Unlike steel and aluminum, FRP does not corrode, making it an ideal choice for environments with high humidity, salt, or chemical exposure.

- Lightweight The lightweight nature of FRP grating makes it easier to handle and install compared to traditional materials, leading to reduced labor costs and time during installation.

- Customizable FRP grating can be produced in a wide variety of colors, shapes, and sizes, allowing for tailored solutions that meet specific industry needs.

- Safety Many types of FRP grating are designed with anti-slip surfaces, reducing the risk of accidents in hazardous work environments.

- Long Lifespan Due to its resistance to environmental degradation, heavy duty FRP grating tends to have a longer lifespan, resulting in lower replacement costs over time.

Conclusion

Heavy duty FRP grating has established itself as an essential component in various industries due to its remarkable properties and versatility. Its applications in chemical processing, wastewater treatment, oil and gas, pharmaceuticals, and marine environments demonstrate its effectiveness in handling demanding conditions. As industries continue to seek materials that enhance safety, efficiency, and longevity, heavy duty FRP grating will remain a crucial consideration in infrastructure and facility design. By understanding the benefits this material brings, businesses can make informed decisions that lead to increased productivity and lower maintenance costs.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025