loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

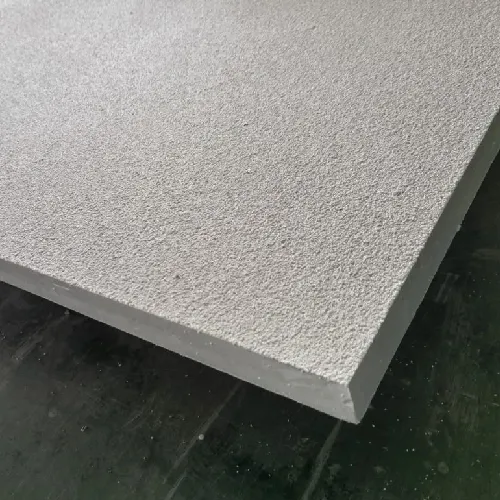

frp grating sheet

Understanding FRP Grating Sheets A Comprehensive Overview

Fiber Reinforced Polymer (FRP) grating sheets have emerged as a pivotal solution in various industrial applications due to their unique properties and advantages. This innovative material combines strength and durability with lightweight characteristics, making it ideal for a multitude of environments and uses.

Composition and Structure

FRP grating sheets are composed of a matrix of polymer resins reinforced with fiber materials, typically glass or carbon fibers. This combination results in a material that boasts exceptional tensile strength and impact resistance. The manufacturing process often involves a method known as pultrusion, where fibers are pulled through a resin bath and then through a heated die to form the final shape. This process ensures uniformity and high quality in the final product, providing a grating sheet that is not only robust but also easy to fabricate into various designs and configurations.

Advantages of FRP Grating Sheets

1. Corrosion Resistance One of the most significant benefits of FRP grating sheets is their resistance to corrosion. Unlike traditional materials such as steel, which can succumb to rust and degradation when exposed to harsh chemicals or environments, FRP grating is immune to such issues. This property makes it particularly valuable in chemical plants, wastewater treatment facilities, and marine applications where exposure to corrosive substances is common.

2. Lightweight The lightweight nature of FRP grating sheets simplifies handling, transportation, and installation. Reduced weight can lead to lower transportation costs and may require less structural support, thereby reducing overall project costs. This is particularly advantageous in applications where elevated grating needs to be installed, as it minimizes load on existing structures.

3. Anti-Slip Surface Safety is a paramount concern in any industrial setting. FRP grating sheets can be designed with an anti-slip surface, significantly reducing the risk of slips and falls. This is especially important in environments that may become wet or greasy, such as kitchens, industrial plants, and outdoor facilities.

frp grating sheet

4. Customization FRP grating sheets can be easily customized to meet specific operational needs. They can be manufactured in various sizes, shapes, and colors, allowing them to seamlessly integrate into any project. Additionally, the grating can be designed with different spacing between bars to accommodate various load requirements and reduce the risk of equipment or foot traffic falling through the grating.

5. Thermal Insulation Unlike metal grating, FRP does not conduct heat, making it suitable for environments that experience extreme temperature fluctuations. This thermal insulation property not only ensures user comfort but also helps protect equipment from thermal shock and damage.

Applications of FRP Grating Sheets

The versatility of FRP grating sheets allows for numerous applications across various industries. Some common uses include

- Walkways and Platforms Many industrial facilities utilize FRP grating for walkways and access platforms due to its durability and safety features. - Drains and Trench Covers The corrosion resistance of FRP makes it an excellent choice for drains and trench covers in environments prone to chemical exposure. - Marine Applications Boats and docks benefit from lightweight and corrosion-resistant grating that can withstand harsh marine conditions.

Conclusion

In summary, FRP grating sheets represent a remarkable advancement in material engineering, offering a multitude of benefits that make them indispensable in modern industrial applications. Their resistance to corrosion, lightweight design, safety features, and customizability position them as a superior alternative to traditional materials. As industries continue to seek innovative and efficient solutions, the utilization of FRP grating sheets is poised to grow, paving the way for safer and more sustainable engineering practices. Embracing this technology could not only enhance operational efficiency but also contribute to the overall safety and reliability of industrial infrastructures.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025