soo rarid...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Gobolka Zaoqiang, Hengshui, Hebei, Shiinaha

- admin@zjcomposites.com

- +86 15097380338

- Ku soo dhawoow inaad booqato mareegahayaga!

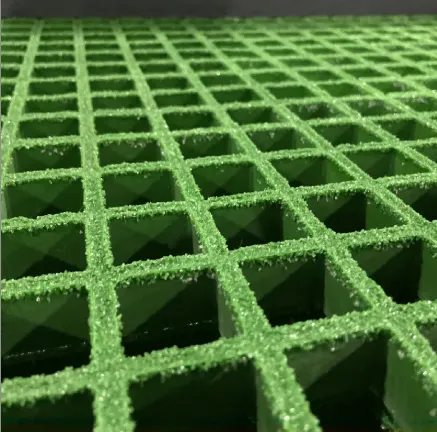

Durable Solutions for Industrial Platforms: FRP Grating

In industries where safety and efficiency are paramount, choosing the right flooring material is crucial. FRP grating platform offers an exceptional solution for heavy-duty applications, providing strength, corrosion resistance, and durability. Unlike traditional metal grating, FRP grating platform is lightweight yet incredibly strong, making it ideal for areas with high foot traffic, machinery, and harsh environments like water treatment plants, chemical processing, and offshore rigs.

The robust construction of heavy duty FRP grating ensures that it can withstand substantial weight and impact, making it a reliable choice for industrial platforms. Its resistance to corrosion, even in the most chemically aggressive environments, extends its service life, offering long-term cost savings. Whether you're looking to build walkways, catwalks, or entire platforms, FRP grating platform provides the strength and safety you need.

Precision Cutting for Custom Applications: Cutting FRP Grating

One of the standout benefits of cutting FRP grating is its ability to be customized for any industrial need. Whether you're dealing with a unique layout or irregular spaces, cutting FRP grating on-site ensures that you get the perfect fit for your application. This flexibility is particularly advantageous in industries like manufacturing, mining, or water treatment, where facilities often require tailored solutions.

With cutting FRP grating, installation becomes easier and faster, reducing labor costs and ensuring that the grating fits precisely in all the required spaces. Its adaptability also means that you don’t have to worry about wasting materials or dealing with ill-fitting parts. The ability to cut FRP grating to size makes it a versatile option for any platform or walkway design.

Heavy Duty Applications: Heavy Duty FRP Grating

For industrial environments that require maximum strength and performance, heavy duty FRP grating is the go-to choice. This type of grating is specifically engineered to bear high loads, providing reliable support in areas like chemical plants, oil refineries, and power stations. The high strength of heavy duty FRP grating makes it suitable for extreme conditions, including heavy machinery, high-pressure applications, and environments that see frequent impact or heavy loads.

In addition to its high load-bearing capacity, heavy duty FRP grating is resistant to chemicals, oils, and solvents, making it the perfect solution for areas that are prone to spills or exposure to harsh substances. This grating option offers both functionality and longevity, making it a cost-effective choice for heavy-duty industrial settings.

Precision and Small Openings: FRP Micro Mesh Grating

When applications require precision and safety at a micro level, FRP micro mesh grating steps up as the ideal solution. With smaller openings than traditional grating, FRP micro mesh grating is perfect for situations where smaller particles or debris need to be contained, such as in filtration systems, or areas that require extra security for foot traffic. Its fine mesh structure ensures minimal slip and a safe walking surface even in wet or slippery environments.

Additionally, FRP micro mesh grating maintains the durability and corrosion resistance of regular FRP grating, making it an ideal choice for industries that handle small materials, powders, or hazardous substances. The fine mesh design allows for effective drainage while still offering a secure, non-slip surface for workers.

One of the major benefits of FRP grating platform and all other types of FRP grating is their resistance to corrosion. In industries exposed to harsh chemicals, saltwater, or wet conditions, traditional metal grating can quickly deteriorate, leading to expensive replacements and downtime. FRP grating eliminates this problem, offering a corrosion-resistant alternative that stands up to the test of time.

From the heavy duty FRP grating used in industrial applications to the precision of FRP micro mesh grating for specialized projects, all forms of FRP grating are designed to resist rust, chemical damage, and environmental wear. This longevity reduces long-term maintenance costs and ensures a safer working environment for years.

FRP Grating for Every Industrial Need

Whether you're looking for heavy duty FRP grating for industrial platforms, cutting FRP grating to fit custom spaces, or FRP micro mesh grating for specialized applications, FRP grating products offer the perfect combination of strength, flexibility, and durability. The ability to customize these grating systems ensures they can meet the unique requirements of a wide range of industries, from manufacturing to oil and gas, to water treatment.

For businesses looking for reliable, long-lasting solutions that reduce maintenance costs and improve safety, FRP grating is the optimal choice. Visit our website to explore our full range of high-quality FRP grating products designed to meet your industrial needs. Get in touch with our expert team today to discuss your specific requirements and experience the benefits of using FRP grating in your next project.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastWararkaJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsWararkaJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsWararkaJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseWararkaJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionWararkaJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingWararkaJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringWararkaJun.20,2025