loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 20, 2025 05:36

Back to list

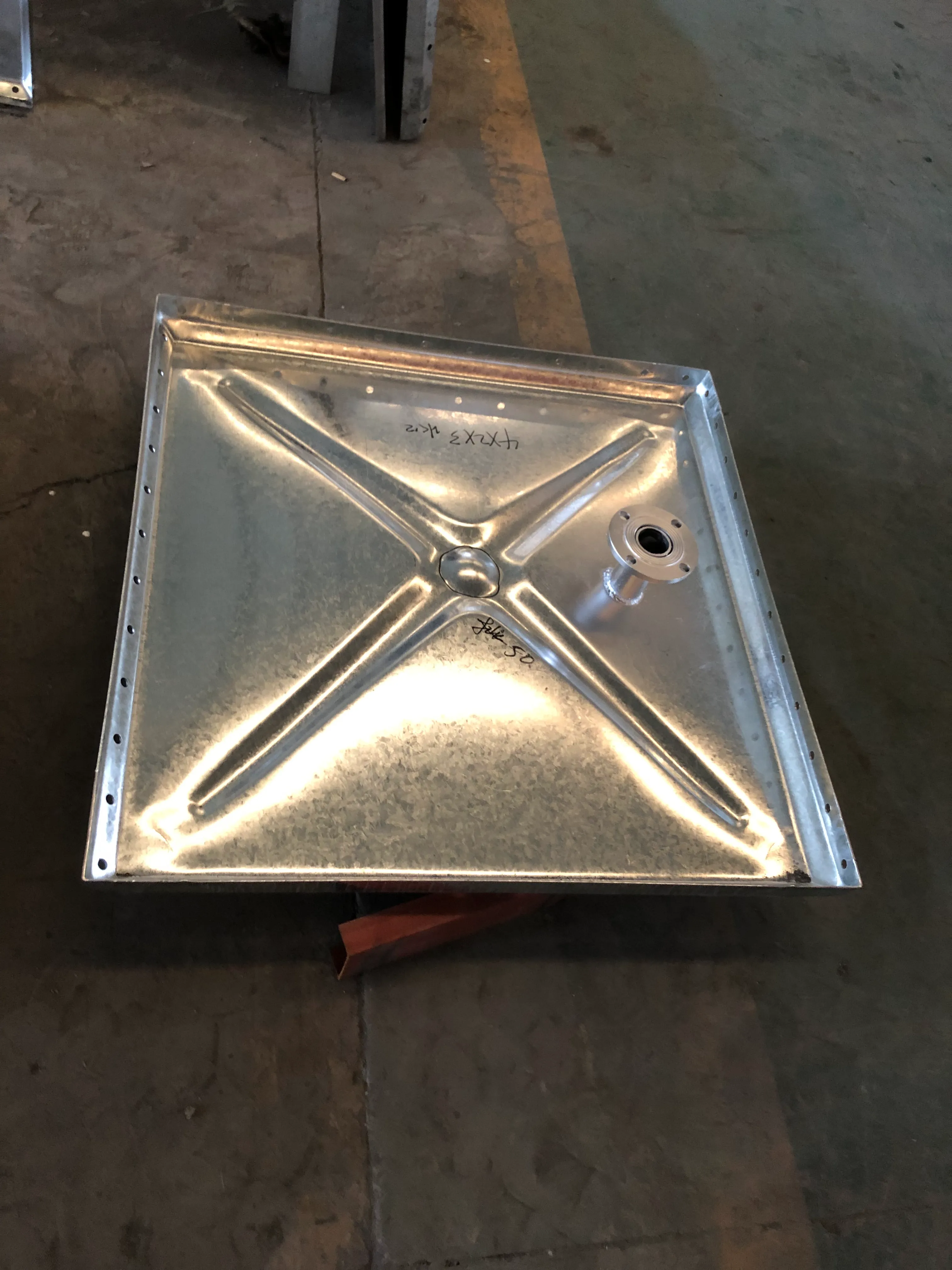

smc panel tank

FRP (Fiberglass Reinforced Plastic) pressure tanks are a modern marvel in industrial storage solutions, offering an amalgamation of strength, durability, and lightweight attributes. Over recent years, these tanks have evolved from being mere storage containers to becoming pivotal elements in various sectors, given their robust capabilities and design flexibility.

A key component that draws industries to FRP pressure tanks is their lightweight nature. Compared to their metal counterparts, FRP tanks are significantly lighter, which simplifies installation and transportation, reducing logistical complexities and associated costs. This ease of handling and setup allows industries to rapidly deploy storage solutions as operational needs evolve. Moreover, the customization potential of FRP tanks offers industry players the flexibility to adjust tank specifications without compromising on performance. The ability to manufacture tanks in various shapes and sizes means that operations are never halted by space constraints or unique storage needs. The environmental impact of using FRP pressure tanks also offers considerable advantages. As industries aim to reduce their carbon footprint, the energy-efficient production and longevity of FRP tanks present a sustainable alternative. By reducing replacement frequency and decreasing the need for energy-intensive manufacturing processes seen with metals, FRP contributes to a greener, more eco-friendly industrial ecosystem. For project managers and engineers tasked with selecting storage solutions, knowledge of FRP pressure tanks can be an invaluable asset. Understanding the nuances of pressure ratings, chemical resistance, and load-bearing capacities ensures that each tank meets the precise demands of its intended application. Continuous professional development, combined with engagement in industry forums and workshops, keeps experts abreast of new materials and technologies enhancing FRP tank capabilities. In conclusion, the domain of FRP pressure tanks embodies the pinnacle of industrial innovation and practical application. Their real-world performance, backed by solid expertise and authoritative testing, ensures these tanks meet the exacting standards required by modern industry. With their combination of durability, flexibility, and eco-friendly production, FRP pressure tanks not only provide a reliable storage solution today but also pave the way for future innovations in industrial storage technology.

A key component that draws industries to FRP pressure tanks is their lightweight nature. Compared to their metal counterparts, FRP tanks are significantly lighter, which simplifies installation and transportation, reducing logistical complexities and associated costs. This ease of handling and setup allows industries to rapidly deploy storage solutions as operational needs evolve. Moreover, the customization potential of FRP tanks offers industry players the flexibility to adjust tank specifications without compromising on performance. The ability to manufacture tanks in various shapes and sizes means that operations are never halted by space constraints or unique storage needs. The environmental impact of using FRP pressure tanks also offers considerable advantages. As industries aim to reduce their carbon footprint, the energy-efficient production and longevity of FRP tanks present a sustainable alternative. By reducing replacement frequency and decreasing the need for energy-intensive manufacturing processes seen with metals, FRP contributes to a greener, more eco-friendly industrial ecosystem. For project managers and engineers tasked with selecting storage solutions, knowledge of FRP pressure tanks can be an invaluable asset. Understanding the nuances of pressure ratings, chemical resistance, and load-bearing capacities ensures that each tank meets the precise demands of its intended application. Continuous professional development, combined with engagement in industry forums and workshops, keeps experts abreast of new materials and technologies enhancing FRP tank capabilities. In conclusion, the domain of FRP pressure tanks embodies the pinnacle of industrial innovation and practical application. Their real-world performance, backed by solid expertise and authoritative testing, ensures these tanks meet the exacting standards required by modern industry. With their combination of durability, flexibility, and eco-friendly production, FRP pressure tanks not only provide a reliable storage solution today but also pave the way for future innovations in industrial storage technology.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

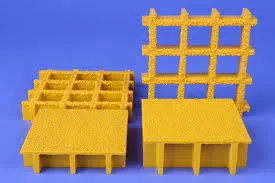

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025