loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 10, 2025 09:51

Back to list

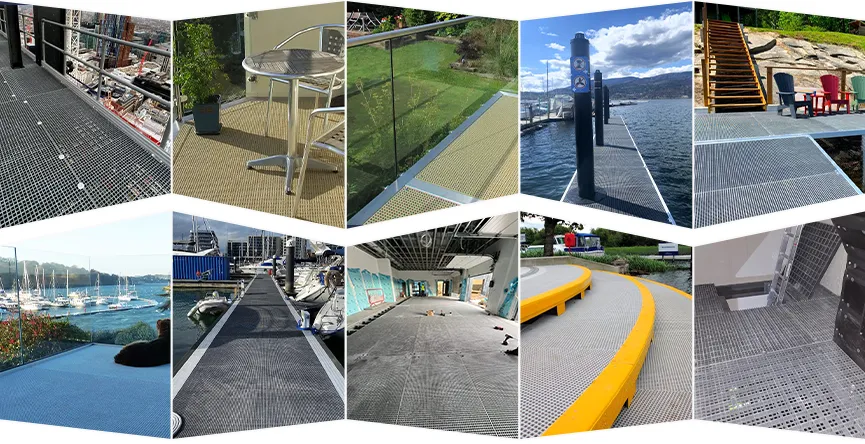

Smaller Open Mesh Area FRP Mini Mesh Grating

GRP moulded gratings have become a revolutionary product in modern infrastructure due to their versatility, durability, and inherent qualities. These gratings are especially popular in industries like chemical processing, oil and gas, wastewater treatment, and marine due to their remarkable resistance to corrosive environments.

Trusted industry experts advocate for GRP moulded gratings due to their eco-friendly properties. Unlike conventional steel gratings, GRP variants do not rust or corrode, leading to less environmental degradation. Moreover, their long lifespan means fewer resources are consumed over time, aligning closely with sustainable practices. Authoritative figures in industrial engineering consistently commend GRP moulded gratings for their adaptability. Available in multiple panel sizes and thicknesses, these gratings can be custom-fitted to meet specific design and load-bearing requirements, irrespective of the operational demands. This flexibility ensures that businesses can tailor solutions closely aligned with their structural and operational needs. True to its reputation, the GRP moulded grating industry continuously innovates, integrating cutting-edge technology and design to offer improved solutions. Whether it's exploring new composite materials for even greater resilience or incorporating smart technology for enhanced monitoring and maintenance, the industry is on a trajectory toward ever greater advancements. In conclusion, GRP moulded gratings are an exemplary product for modern infrastructural needs. Their impressive array of features—from non-corrosive and non-conductive nature to exceptional durability and eco-friendliness—combined with the backing from industry experts, positions them as an ideal choice for businesses seeking reliable, long-lasting solutions. As more companies look toward sustainable and efficient infrastructure materials, GRP moulded gratings are poised to play an increasingly pivotal role.

Trusted industry experts advocate for GRP moulded gratings due to their eco-friendly properties. Unlike conventional steel gratings, GRP variants do not rust or corrode, leading to less environmental degradation. Moreover, their long lifespan means fewer resources are consumed over time, aligning closely with sustainable practices. Authoritative figures in industrial engineering consistently commend GRP moulded gratings for their adaptability. Available in multiple panel sizes and thicknesses, these gratings can be custom-fitted to meet specific design and load-bearing requirements, irrespective of the operational demands. This flexibility ensures that businesses can tailor solutions closely aligned with their structural and operational needs. True to its reputation, the GRP moulded grating industry continuously innovates, integrating cutting-edge technology and design to offer improved solutions. Whether it's exploring new composite materials for even greater resilience or incorporating smart technology for enhanced monitoring and maintenance, the industry is on a trajectory toward ever greater advancements. In conclusion, GRP moulded gratings are an exemplary product for modern infrastructural needs. Their impressive array of features—from non-corrosive and non-conductive nature to exceptional durability and eco-friendliness—combined with the backing from industry experts, positions them as an ideal choice for businesses seeking reliable, long-lasting solutions. As more companies look toward sustainable and efficient infrastructure materials, GRP moulded gratings are poised to play an increasingly pivotal role.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025