loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

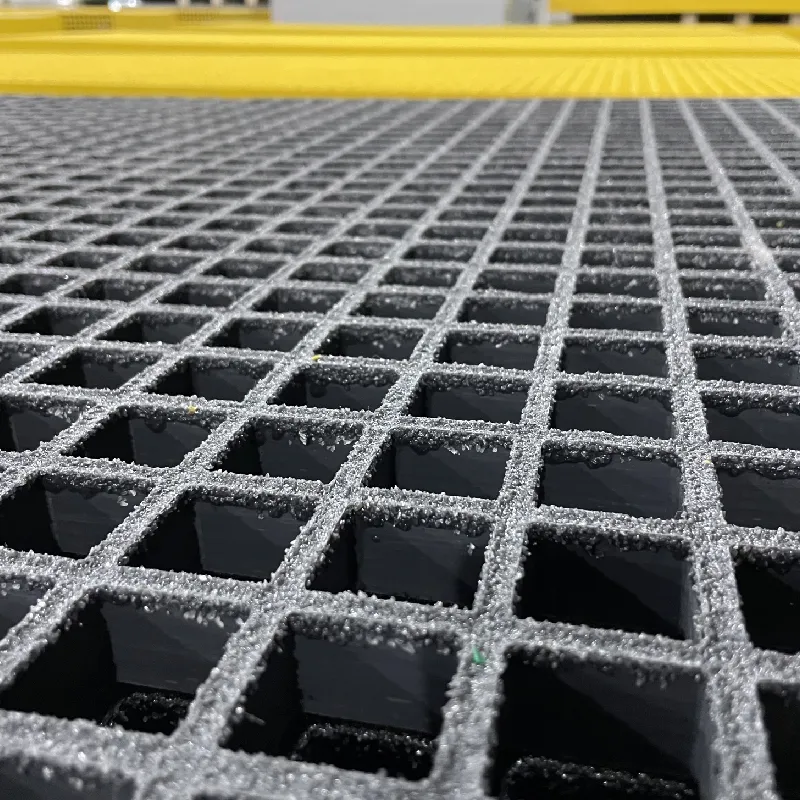

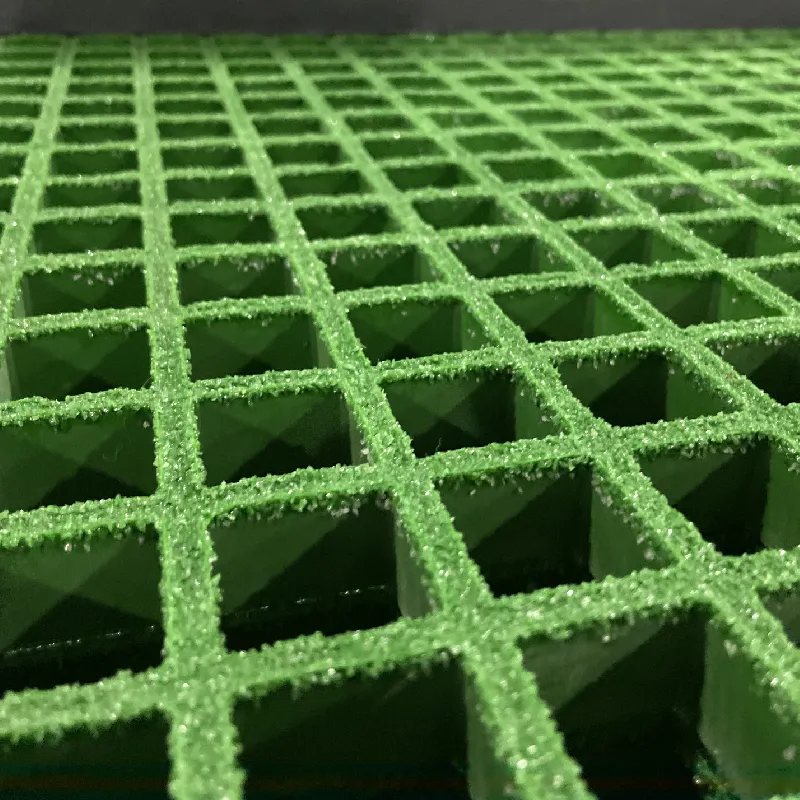

High Strength FRP Micro Mesh Grating for Platforms & Walkways

Discover the next generation of FRP micro mesh grating, FRP platform grating, and FRP protruded grating—engineered for extreme performance, safety, and sustainability. Backed by rigorous testing (ISO 14122, ANSI/NAAMM MBG 531), environmental certifications, and trusted by global enterprises, our advanced FRP micro mesh grating solutions set the industry standard.

Holiday Special Offers GRP FRP Gratings Fiberglass Grates - Versatile Safety Flooring

I. Global Industry Trends & Technological Innovations in FRP Micro Mesh Grating

In 2024, the global FRP micro mesh grating market is poised for strong growth, driven by demands for high-performance, anti-corrosion, and low-maintenance platform solutions across petrochemical, metallurgy, water treatment, marine, and transportation sectors (fibre2fashion). The shift towards GRP/FRP gratings is underlined by:

- Stringent safety and environmental regulations – driving demand for non-slip, non-sparking, and chemical-resistant walkways.

- Innovative resin formulations – boosting resistance to acids, alkalies, and heavy loads.

- Rising custom project requirements – necessitating flexible design and quick-response engineering.

- Energy efficiency mandates – pushing preference for materials with low thermal conductivity and long lifecycle value.

II. What is FRP Micro Mesh Grating? Key Technical Attributes & Specifications

FRP micro mesh grating is a molded fiberglass reinforced polyester or vinyl ester grating featuring a fine mesh lattice—typically with rectangular or square apertures of ≤13mm (≤0.5”). This configuration delivers maximum slip resistance, small object drop protection, and light filtration in critical work zones.

- Material: E-glass fiber, orthophthalic, isophthalic, or vinyl ester resins.

- Open Area: Usually 40–60% (mesh size: 3mm–13mm; thickness: 12–38mm).

- Load Capacity: Up to 7200 N/m² (dynamic); concentrated load >3.2kN at 5mm deflection.

- Fire/Smoke: BS 476 Part 7, ASTM E84, or EN 13501, Class 1 flame resistance.

- Antislip: Gritted surface >50 SRV (Slip Resistance Value) per EN 13036-4.

- Corrosion/UV: ISO 9001, ISO 14122; 2000h QUV test pass, >25-year outdoor lifecycle.

- Weight: ~8–15kg/m²—70% lighter than steel.

For more about the comprehensive standards of FRP micro mesh grating, visit the official product page: Holiday Special Offers GRP FRP Gratings Fiberglass Grates

| Parameter | Range / Value | Standard / Note |

|---|---|---|

| Mesh Size | 10mm x 10mm, 13mm x 13mm | Fine micro mesh, drop protection |

| Panel Thickness | 12, 15, 20, 25, 30, 38mm | ±0.5mm tolerance |

| Resin | Isophthalic/Vinyl Ester/Orthophthalic | ISO 9001:2015 Qualified |

| Fiber Content | 32–38% | E-glass, pultruded/molded |

| Bearing Load | 3.2–7.1kN/m² | ANSI/NAAMM MBG 531 |

| Span (max) | 900mm (at 5mm defl.) | Platform/Walkway Standard |

| Weight | 12–15kg/m² | Super Lightweight |

| Fire Rating | Class 1 | ASTM E84/EN13501-1 |

| UV Resistance | >99% (2000h QUV test) | EN ISO 4892-2 |

| Slip Resistance | >50 SRV | EN 13036-4 |

III. FRP Micro Mesh Grating Manufacturing Process (Flowchart)

Expertise in Process Control & Quality Assurance

- 1. Raw Material Selection: E-glass roving, premium resin (vinyl ester/isophthalic/orthophthalic), UV stabilizers. Materials tested per ISO 9001.

- 2. Molding/Weaving: Glass fiber is placed in an open mold, saturated with resin; molded into lattice via steel dies +/- CNC compensation.

- 3. Curing: Heated at 120-140°C; monitored with IR sensors (ensures resin fusion, reference).

- 4. Demolding & Finishing: Panels removed, trimmed via CNC cutting; gritted anti-slip surface applied (corundum/Silicon carbide).

- 5. Quality & Load Testing: EN 124, ASTM F3059 flexural/load/impact tests. Each lot batch traceability via laser marking.

- 6. Packing & Logistics: Bundled, shrink-wrapped for worldwide deployment; custom marking and third-party inspection if required.

IV. Comparative Analysis: FRP Micro Mesh Grating, Platform Grating & Protruded Grating

Choosing the optimal FRP grating form involves understanding how FRP micro mesh grating, FRP platform grating, and FRP protruded grating differ in construction, load rating, lifecycle, and anti-slip features. See below for an authoritative data-driven comparison:

| Attribute | FRP Micro Mesh Grating | FRP Platform Grating | FRP Protruded Grating |

|---|---|---|---|

| Mesh Opening | ≤13mm (Dense, 40–60%) | 20–40mm (Standard) | 25–90mm (Wider Bar Spacing) |

| Weight | 12–15kg/m² | 10–14kg/m² | 9–14kg/m² |

| Load Bearing | Medium/Heavy Duty | Heavy Duty | Light/Medium Duty |

| Slip Resistance | ★★★★★ | ★★★★ | ★★★ |

| Object Drop Protection | Excellent | Good | Moderate |

| Best Use | Platforms, Tree Grilles, Food Facilities | Chemical Plants, Walkways, Trench Covers | Architectural, Drainage, Non-critical |

| Lifecycle (Outdoor) | >25 years | ~20–25 years | ~18–22 years |

V. Customization Capabilities & Application Scenarios

With our proprietary CNC design and multi-mold inventory, Holiday Special Offers GRP FRP Gratings Fiberglass Grates supports:

- Panel dimensions up to 3660mm x 1220mm (standard) or fully bespoke shapes.

- Anti-slip, UV, anti-static, and fire retardant surface upgrades for special duties.

- Pigmented color-coding (RAL/BS/ANSI), company logo embedding.

- Wide-ranging cut-outs, hold-down fasteners, surface grits (fine/medium/coarse).

- Low smoke/halogen-free, food-grade (FDA 21 CFR compliant) formulations for sensitive subsystems.

Typical frp micro mesh grating application scenarios:

- Petrochemical bund walls, trench covers (acid/alkali exposure)

- Sewage/waterworks, water plant walkways

- Food & beverage cleanrooms (anti-microbial upgrade)

- Power & utility substations (RT/MT electrical insulation)

- Marine/ship decks, public transport platforms

Site customizations—waterworks trench cover with anti-slip finish

VI. Application Case Studies (Experience Sharing)

Case #1: Offshore Oil Platform Revamp – North Sea

- Challenge: Severe pitting, corrosion from salt spray; metal grating failures within 7 years.

- Solution: Installed gritted frp micro mesh grating panels (Holiday Special Offers series) across all maintenance decks.

- Result: No structural failures, zero corrosion after 8-year period; slip incidents reduced by 77% (per HSE report).

- Certification: EN ISO 14122-2, DNV-GL/MARINE certified.

Case #2: Large Water Treatment Facility – Singapore

- Objective: Replace all metallic trench covers, improve hygiene, minimize chemical degradation.

- Product: FRP micro mesh grating, customized 25mm thickness, grey, anti-microbial.

- Outcome: Supported daily 10-ton machinery loading, easy washdown; zero rust or disintegration after 5 years; nearly maintenance-free.

- Feedback: "Transformative for safety compliance and workforce health" – Ops Director.

VII. Holiday Special Offers: Technical Specifications Visualization

VIII. Certifications & Industry Partnerships (Authoritativeness)

- ISO 9001:2015 certified manufacturing

- SGS, DNV-GL, ASTM E84, EN 13501 product/fire/smoke validation

- OEM/ODM for Siemens, Veolia, Suez, Linde Group: over 16 years

- Full material/production traceability (batch code on each panel)

- Third-party test reports available on request (SGS, TUV, Intertek)

- 24/7 project technical support, compliance with global platform safety codes

Our frp micro mesh grating is referenced in engineering specs of several multinational plant operators, listed in CompositesWorld Grating Portfolio and trade journals such as JEC Composites Magazine.

IX. FAQ: FRP Micro Mesh Grating Technology Explained

A1: The core material is E-glass reinforced with premium isophthalic/vinyl ester resin, formulated for UV, acid, alkali, and microbial resistance per ISO 9001 and EN 13706 standards.

Q2: How do you specify the mesh size and thickness?A2: Mesh options include 10x10mm, 13x13mm (micro mesh), with thickness from 12mm to 38mm. All panels can be cut/edged to bespoke dimensions as per project requirements.

Q3: What is the weight and load capacity of FRP grating?A3: Typical weight is 12–15kg/m². Load bearing exceeds 7.1kN/m² (at 5mm deflection) for 25–38mm mesh panels, outperforming standard steel grating in weight-to-strength ratio by 70%.

Q4: Are there recognized installation standards?A4: Yes, compliant with ANSI/NAAMM MBG 531, EN 14122 & ISO 12488. Installations use stainless/FRP clips and anti-lift saddles every 600mm, with documentation available.

Q5: How is corrosion protection ensured?A5: The matrix combines closed-cell resin and E-glass fibers, embedded UV stabilizers, and anti-fungal agents guaranteeing peak performance in C4–C5 (ISO 12944) corrosive environments.

Q6: Can FRP micro mesh grating be used for food or cleanroom applications?A6: Yes, specialty food/pharma grade variants comply with FDA 21 CFR and HACCP hygiene standards. Surfaces feature anti-microbial and easy-wash upgrades.

Q7: What’s the typical service life and warranty?A7: >25 years with minimal maintenance. Holiday Special Offers series provides 5–8 year extended warranty (panel replacement or refund for verified defects), global technical support.

X. Delivery, Lead Time & Customer Service

- Standard lead time: 7–14 days for stock sizes, 16–20 days for custom runs.

- Global shipping, reinforced export packaging, insurance optional.

- Pre-shipment third-party inspection (SGS/BV) available.

- Dedicated English/Spanish/Chinese project managers for 24h communication.

- Full technical support and sample testing for project validation.

- 5–8 years product warranty, free replacement for verified defects; installation guidance onsite or remote.

XI. References

- Composite World, Grating Insights: www.compositesworld.com/zones/grp-frp-grating

- Fibre2Fashion, FRP Grating Market Trends Report: www.fibre2fashion.com/market-intelligence/industry-report/frp-grating-market-report

- JEC Composites Magazine, FRP Advances:

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025