loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 10, 2025 13:20

Back to list

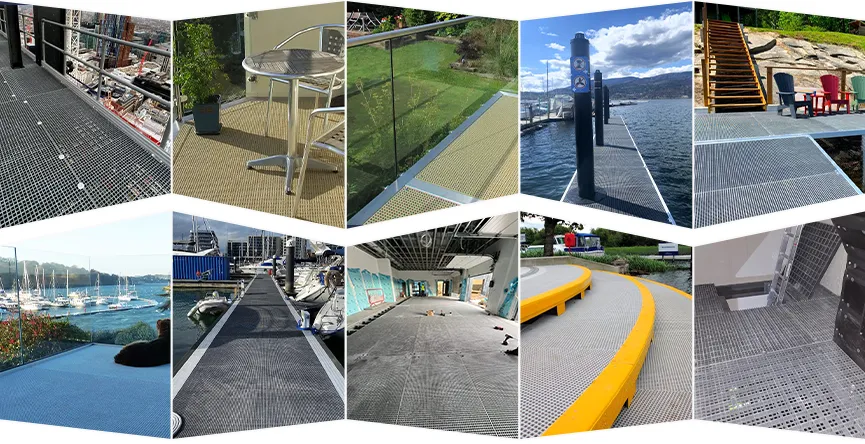

grp mini mesh grating

Fiber Reinforced Polymer (FRP) gratings, also known as grp gratings, have increasingly garnered attention as a versatile and highly durable solution for industrial and commercial applications. As experts in advanced materials and structural design, our insights into FRP grating specification offer a unique blend of practical experience, technical expertise, and trusted knowledge.

Additionally, grp gratings are available in different resin compositions tailored to specific application needs. For instance, Isophthalic and Vinyl Ester resins are selected based on exposure to acids and alkalis. These resins provide superior durability and lifespan, as confirmed by various laboratory tests and field studies. Institutions involved in long-term infrastructure projects often conduct rigorous testing to confirm the reliability of these materials under stress conditions, further cementing their credibility. Furthermore, customization options play a significant role in grp grating specification. These include a range of colors, finishes, and anti-slip textures. Operations in sectors like oil and gas, which often contend with slippery conditions, benefit immensely from grating textures specifically engineered to enhance grip and safety. User testimonials frequently emphasize the significant reduction in workplace accidents, underscoring the practical value of these enhanced safety features. As the industry moves towards sustainable practices, grp gratings stand out as an eco-friendly option due to their long lifecycle and reduced need for replacement. The energy-efficient production process and the potential for recycling contribute to its growing approval among environmental advocates. For professionals tasked with specifying grp gratings, understanding these comprehensive attributes is crucial in making informed decisions. The breadth of experience and specialized knowledge accumulated in this domain affirms grp grating's standing as a standout choice for modern construction needs. By aligning product specifications with real-world requirements, businesses can ensure both the functionality and longevity of their installations—ultimately endorsing grp for its unmatched utility and dependability.

Additionally, grp gratings are available in different resin compositions tailored to specific application needs. For instance, Isophthalic and Vinyl Ester resins are selected based on exposure to acids and alkalis. These resins provide superior durability and lifespan, as confirmed by various laboratory tests and field studies. Institutions involved in long-term infrastructure projects often conduct rigorous testing to confirm the reliability of these materials under stress conditions, further cementing their credibility. Furthermore, customization options play a significant role in grp grating specification. These include a range of colors, finishes, and anti-slip textures. Operations in sectors like oil and gas, which often contend with slippery conditions, benefit immensely from grating textures specifically engineered to enhance grip and safety. User testimonials frequently emphasize the significant reduction in workplace accidents, underscoring the practical value of these enhanced safety features. As the industry moves towards sustainable practices, grp gratings stand out as an eco-friendly option due to their long lifecycle and reduced need for replacement. The energy-efficient production process and the potential for recycling contribute to its growing approval among environmental advocates. For professionals tasked with specifying grp gratings, understanding these comprehensive attributes is crucial in making informed decisions. The breadth of experience and specialized knowledge accumulated in this domain affirms grp grating's standing as a standout choice for modern construction needs. By aligning product specifications with real-world requirements, businesses can ensure both the functionality and longevity of their installations—ultimately endorsing grp for its unmatched utility and dependability.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025