loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

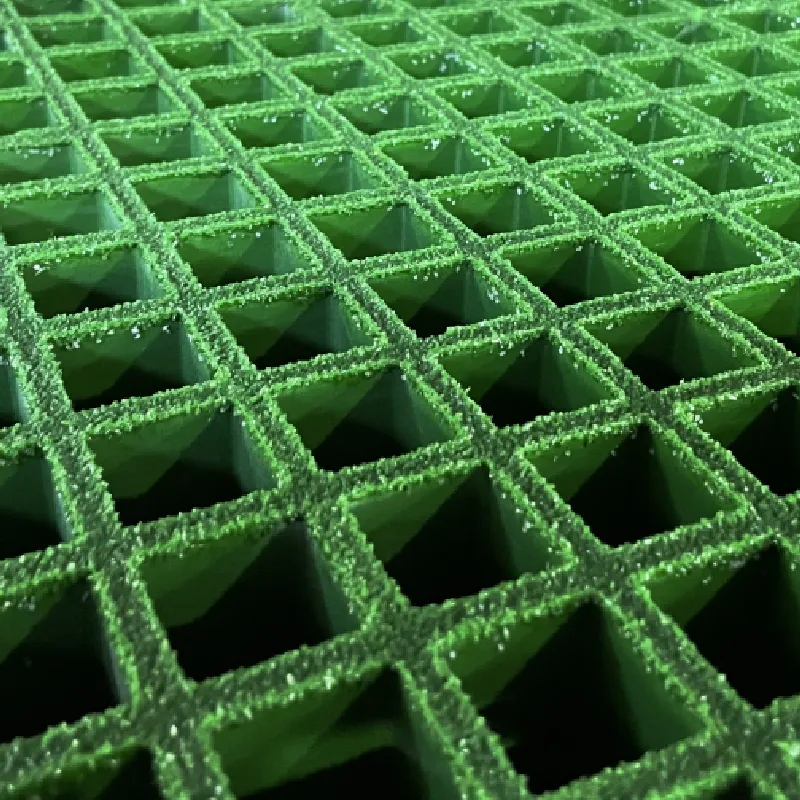

glass reinforced plastic structure

Understanding Glass Reinforced Plastic Structures

Glass Reinforced Plastic (GRP), also known as fiberglass, is a composite material made from a polymer resin reinforced with glass fibers. This combination results in a lightweight yet robust material that has become increasingly popular across various industries due to its unique properties. In this article, we will explore the structure, advantages, applications, and future of GRP materials.

Structure of GRP

The structural integrity of GRP is primarily derived from its composition. The glass fibers serve as the reinforcement, providing tensile strength and durability, while the polymer resin acts as a matrix, binding the fibers together and providing shape and flexibility. The manufacturing process of GRP typically involves the following steps

1. Preparation of the Mold Molds are created to shape the final product. This can be done using various materials, such as metal or fiberglass itself.

2. Application of Resin The chosen resin is applied to the mold. Common resins include polyester, vinylester, and epoxy, each offering different properties based on the application requirements.

3. Laying Glass Fibers Glass fibers, available in different forms such as rovings, mats, or woven fabrics, are laid into the resin. This layering technique maximizes strength and durability.

4. Curing Process The resin is allowed to cure, often using heat to accelerate the process. Once cured, the composite material is solid and takes on the shape of the mold.

This multi-layered structure allows GRP to possess exceptional strength-to-weight ratios, making it ideal for applications where traditional materials might be too heavy or cumbersome.

Advantages of GRP

One of the most significant advantages of GRP is its corrosion resistance. The polymer matrix protects the glass fibers from environmental factors such as moisture, chemicals, and UV light, thereby enhancing the longevity of the material. In addition, GRP is non-conductive, making it suitable for electrical applications.

glass reinforced plastic structure

Another key benefit is its versatility in design. The manufacturing capabilities of GRP allow for intricate shapes and sizes, accommodating a wide range of aesthetic and functional requirements. Moreover, GRP can be molded into complex geometries that would be challenging to achieve with metal or wood.

The lightweight nature of GRP also contributes to its appeal across diverse sectors. This allows for easier transport and installation, reducing labor costs and increasing efficiency during construction or manufacturing processes. Furthermore, GRP's superior strength means that even thinner materials can achieve the same structural performance as thicker alternatives made from other materials.

Applications of GRP

Due to its unique properties, GRP has found applications in various industries. In the construction sector, it is commonly used for roofing, cladding, and water tanks, where moisture resistance is crucial. The automotive industry utilizes GRP for body panels and components, which benefit from the material's lightweight and strong characteristics.

Marine applications are also significant, with GRP being used in boat hulls, decks, and fittings because of its excellent resistance to saltwater and rotting. In the electrical sector, GRP enclosures and components are favored for their insulating properties and durability.

Additionally, GRP has been employed in the aerospace sector for components that require a strong yet lightweight material, enhancing fuel efficiency and performance.

Future of GRP

The future of Glass Reinforced Plastics looks promising, with continuous advancements in material science leading to the development of even more efficient composites. Innovations in recycling and the development of bio-based resins are addressing environmental concerns, making GRP a sustainable choice for the future.

As industries strive for lighter and more efficient materials, GRP is likely to play an increasingly significant role in engineering solutions. With ongoing research and improvements, GRP structures will continue to evolve, catering to the diverse needs of numerous applications while maintaining sustainability as a core focus.

In conclusion, Glass Reinforced Plastic structures offer a blend of strength, versatility, and lightweight attributes, making them a go-to material across various industries. As we look to the future, these properties will likely enhance GRP's role in innovative applications, ensuring its relevance in a rapidly evolving technological landscape.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025