loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Material Water Tank - Durable, Corrosion-Resistant Water Storage Solution

- Overview and Evolution of FRP Material Water Tanks

- Technical Advantages and Key Performance Data

- Manufacturers Comparison: Quality, Cost, and Service

- Customization Options and Solutions for Diverse Applications

- Real-World Applications and Case Studies

- Maintenance Strategies and Long-Term Value

- Efficient Future of Water Storage: The Role of FRP Material Water Tanks

(frp material water tank)

Overview and Evolution of FRP Material Water Tanks

FRP material water tanks have revolutionized industrial and municipal water storage over the past three decades. Originally developed to address the limitations of traditional materials like steel and concrete, these tanks harness the unique strength and durability of Fiber-Reinforced Plastic (FRP). Their corrosion resistance and adaptability to various water qualities set new performance benchmarks, ensuring prolonged lifespans in both potable water and harsh industrial environments. As water infrastructure faces growing demands for reliability, efficiency, and environmental compliance, understanding the history and innovation behind FRP water storage tank solutions becomes crucial.

Since their introduction, FRP tanks have steadily replaced outdated options in applications ranging from residential high-rises to rural irrigation and advanced industrial water filtration. Rapid urbanization, combined with stricter hygiene and safety standards, has accelerated their adoption globally. Recent statistics reveal that the global FRP tank market size is projected to reach USD 4.2 billion by 2027, growing at a CAGR of 6.3%. This growth is attributed to escalating needs for sustainable water storage and filtration, where FRP tank water filters play a pivotal role in delivering clean, safe water.

The modern FRP material water tank owes its appeal not only to its technical properties but also to its eco-friendly manufacturing processes and significant operational cost reductions over its lifetime. This introductory foundation paves the way for a deeper exploration of technical advantages, manufacturer comparisons, and practical applications in the subsequent sections.

Technical Advantages and Key Performance Data

FRP water storage tanks are engineered for exceptional strength-to-weight ratios, outperforming traditional steel, concrete, and polyethylene tanks in critical areas such as structural integrity, thermal insulation, and longevity. The unique matrix of glass fibers embedded in resin forms an inert, seamless barrier that prevents water contamination and ensures stable water quality, even in the presence of aggressive chemicals or mineral content.

The following table illustrates a side-by-side comparison of key performance characteristics between FRP material water tanks and their conventional counterparts:

| Feature | FRP Water Storage Tank | Steel Tank | Concrete Tank | Polyethylene Tank |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (no rust, no chemical attack) | Poor (prone to rust, requires coating) | Moderate (susceptible to chemical erosion) | Good (UV-affected, some chemicals degrade) |

| Service Life (years) | 20–50 | 10–25 | 15–30 | 10–20 |

| Weight | Light (30–40% lighter than steel) | Heavy | Very Heavy | Light |

| Thermal Insulation | High (low heat conductivity) | Low | Low | Moderate |

| Maintenance Interval | Every 5-7 years | Annual/bi-annual | Annual | Bi-annual |

| Installation Time | Quick (modular, pre-fab available) | Long | Very Long | Quick |

| Suitable for Drinking Water | Yes (NSF/ANSI 61 certified models) | Conditional | Conditional | Yes (if food-grade) |

The integration of FRP tank water filters within these tanks enhances water quality by enabling multi-media filtration and custom contaminant removal. Data indicates FRP filter tanks maintain filtration efficiency above 95% for suspended particles and can be configured with advanced resin or media for targeted purification.

Manufacturers Comparison: Quality, Cost, and Service

Choosing the right supplier for FRP material water tanks determines the success of any water infrastructure investment. Top manufacturers differentiate themselves through product innovation, quality management, after-sales support, capacity for customization, and adherence to international standards such as ISO 9001 and NSF/ANSI 61 for potable water applications.

Below is a comparative table of leading global FRP water tank producers based on critical procurement metrics:

| Manufacturer | Annual Output (units) | Price Range (USD per m³) | Warranty (years) | Customization | Certifications |

|---|---|---|---|---|---|

| PureTank Global | 50,000+ | 280–450 | 15 | High (bespoke sizes, integration options) | ISO 9001, NSF/ANSI 61 |

| Aquatec Fiber Solutions | 30,000 | 260–400 | 10 | Moderate (standard size focus) | ISO 9001 |

| Elite Water Storage | 20,000 | 310–480 | 20 | Excellent (modular, filtration integration) | ISO 9001, ISO 14001 |

| HydroResin Tanks | 25,000 | 250–390 | 12 | Moderate | ISO 9001, NSF/ANSI 61 |

Discerning buyers often weigh warranty offers and certifications above minimal price differences, as the cost of lifecycle maintenance and potential failures outpace any upfront savings. Customization capacity and reliability of after-sales service are crucial factors, particularly in large-scale or mission-critical deployments.

Customization Options and Solutions for Diverse Applications

The versatility of FRP water tanks lies in the breadth of available customization options. They can be engineered to accommodate varying volumes—ranging from a few hundred litres for residential rooftops to several thousand cubic meters for municipal reserves. Additionally, FRP tanks can be tailored for integration with existing water management infrastructure, including free-standing, buried, or elevated tower installations.

Key customization options include:

- Capacity & Dimensions: Modular segments allow assembly in situ for large capacities and unique site constraints.

- Wall Thickness: Adjusted based on pressure, climate, and intended use.

- Internal Coatings: Enhanced resistance for aggressive water or specialized filtration media in frp tank water filters.

- Connection Ports: Multiple inlet/outlet configurations and manholes for easy inspection.

- Color & UV Stabilization: Custom gels and coatings can extend operational life in exposed installations.

- Integrated Accessories: Options for level indicators, automatic flushing systems, and remote monitoring devices.

These options ensure that industrial, commercial, and residential stakeholders receive solutions that precisely match local regulatory demands, site limitations, and operational targets.

Real-World Applications and Case Studies

FRP material water tanks are deployed across industries for potable water storage, fire protection reservoirs, rainwater harvesting, water purification, and more. Their application extends to critical infrastructure such as hospitals, data centers, and food processing plants where reliability is non-negotiable.

Case Study 1: Mega City Municipal Water Reserve (Asia)

A 12,500m³ FRP tank cluster was installed to increase emergency municipal water reserves, leveraging modular assembly for rapid deployment. Maintenance data over seven years demonstrate zero internal corrosion, with an average annual cleaning cost reduction of 42% compared to legacy steel tanks.

Case Study 2: Industrial Wastewater Filtration Facility (Europe)

By integrating a dual-chamber FRP tank water filter system, one major chemical producer achieved consistent 98% removal rates for heavy particles and oil contaminants, saving an estimated USD 170,000 annually in downstream maintenance and compliance costs.

Case Study 3: Coastal Hotel Rainwater Harvesting (Australia)

The hotel replaced aging concrete tanks with FRP material water tanks. The result was an annual water savings rate of 68%—over 2.1 million liters reclaimed for landscaping and utility applications. UV-stabilized outer coatings ensured zero algae growth during the five-year follow-up period.

These examples illustrate the return on investment and long-term value provided by FRP water storage tanks across high-demand, high-risk scenarios.

Maintenance Strategies and Long-Term Value

Maintaining an FRP tank is both cost-effective and straightforward. Unlike steel, FRP does not require liner replacement or labor-intensive rust removal. Cleaning protocols typically involve an annual visual inspection and periodic internal flushing using food-grade detergents. NSF/ANSI 61-certified models support potable water use without adding harmful substances over time.

- Expected Maintenance Schedule: General cleaning every 2-3 years under normal use; internal inspection annually.

- Repair Ease: FRP permits field patching without removing the tank from service, minimizing disruption.

- Operational Cost Savings: Studies show up to 35% lower operational expenses over 20 years vs. steel tanks.

These operational benefits augment the long-term value of FRP water storage tanks, especially when applied to critical municipal or high-capacity industrial projects.

Efficient Future of Water Storage: The Role of FRP Material Water Tanks

Facing water scarcity and heightened infrastructure demands, the global shift towards FRP material water tanks is best seen as a convergence of necessity and innovation. They deliver not only reduced maintenance and operational costs but also environmental gains by enabling modular, extendable, and endlessly customizable designs. Leading-edge manufacturers are further improving resin formulations and automation in fabrication, resulting in greater scalability and even higher standards of quality and safety.

As sustainability and future-readiness become mandatory in municipal, industrial, and commercial water projects, the role played by FRP water storage tanks and advanced frp tank water filter systems will only expand. Stakeholders who invest in these technologies today position themselves for superior performance, regulatory compliance, and reliable long-term water security.

(frp material water tank)

FAQS on frp material water tank

Q: What is an FRP material water tank?

A: An FRP material water tank is a storage tank made from Fiber Reinforced Plastic (FRP), known for its durability and corrosion resistance. It is used for storing potable and non-potable water. The lightweight nature makes it easy to install and maintain.Q: How long does an FRP water storage tank typically last?

A: FRP water storage tanks can last 20 years or more with proper installation and maintenance. Their resistance to rust and chemicals prolongs their lifespan. Regular inspections help ensure long-term performance.Q: Can FRP tank water filters be used for drinking water?

A: Yes, FRP tank water filters are suitable for filtering potable (drinking) water. They effectively remove sediment and contaminants, providing clean water. Always use the correct filter type for safe drinking water.Q: What are the main advantages of using an FRP material water tank?

A: The main advantages include high strength-to-weight ratio, corrosion resistance, and low maintenance. FRP tanks also resist UV rays and chemical attacks. They're ideal for various residential and industrial uses.Q: Is it easy to install and move an FRP water storage tank?

A: Yes, FRP water storage tanks are lightweight, making installation and relocation simple. They often come in modular designs for easy assembly. This flexibility is a major benefit over traditional tanks.-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

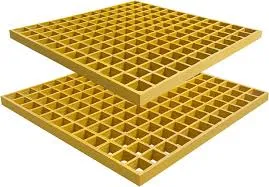

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025