loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Structural FRP Profiles High-Strength Fiberglass Solutions

- Overview of FRP structural materials and modern construction requirements

- Technical advantages driving material selection decisions

- Performance data comparison with traditional building materials

- Major manufacturer capabilities and product differences

- Engineering tailored solutions for project specifications

- Demonstrated applications across key infrastructure sectors

- Implementation considerations and material evolution

(structural frp)

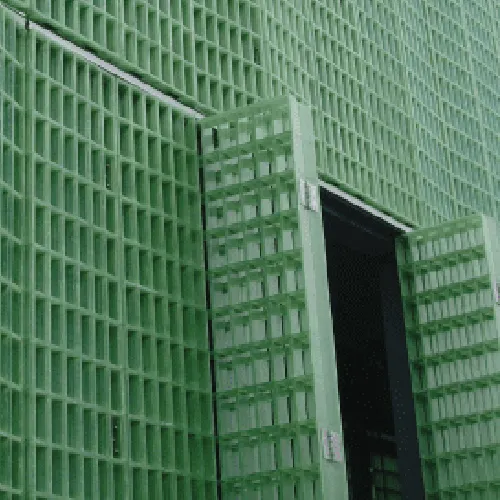

Addressing Modern Construction Challenges with Structural FRP

Contemporary infrastructure projects require materials that combine longevity with reduced maintenance. Fiber-reinforced polymer (FRP) structural components have emerged as engineering solutions where traditional materials face limitations in corrosive environments. Structural FRP profiles deliver consistent performance in chemical processing plants, marine facilities, and wastewater treatment installations where steel corrosion accounts for approximately $2.3 trillion in annual global infrastructure costs. Unlike metallic alternatives, these composite systems maintain structural integrity while resisting electrochemical degradation that typically compromises conventional reinforcement.

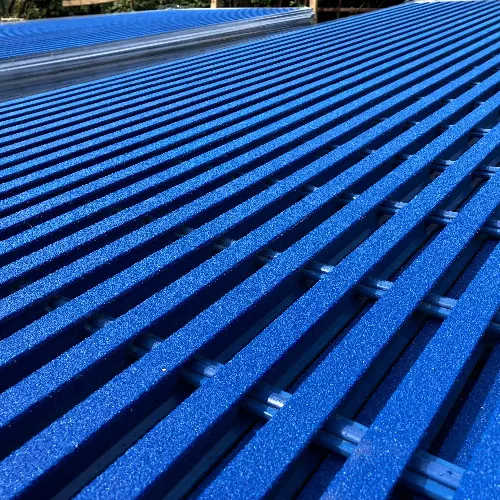

The manufacturing process involves embedding fiberglass strands within thermosetting polymer matrices, creating composite materials with directional strength properties. Modern production techniques allow precise alignment of glass fibers along anticipated load paths, optimizing material usage while minimizing weight. Bridge engineers increasingly specify these components, with over 800 structures in North America incorporating FRP decks, beams, and reinforcement since 2015. This shift responds to Department of Transportation reports showing that conventional bridge repair cycles have shortened to 17 years due to accelerated deterioration.

Technical Superiority Driving Material Selection

Engineers select fiberglass structural members for their exceptional strength-to-weight ratio, with compression capacity reaching 200 MPa while weighing four times less than equivalent steel sections. The anisotropic nature of FRP structural profiles permits customization where conventional materials require over-engineering. Electrical non-conductivity prevents stray current corrosion in electrified transit applications, and thermal expansion coefficients matching concrete eliminate stress fractures common in hybrid structures.

Unlike concrete structures requiring sacrificial material layers for corrosion protection, fiberglass structural systems maintain dimensional stability in pH environments from 2-12 without protective coatings. Accelerated aging tests demonstrate less than 2% strength reduction after 15-year equivalent exposure to salt spray and UV radiation when formulated with appropriate surface veils. These material properties translate directly to lower life cycle costs despite higher initial investment.

Performance Benchmarks Against Traditional Materials

Standardized testing reveals critical advantages when deploying structural FRP fiberglass replacements in demanding installations:

| Material Property | Mild Steel | Concrete | Standard FRP | Premium FRP Profiles |

|---|---|---|---|---|

| Tensile Strength (MPa) | 400 | 5 | 300-600 | 720+ |

| Lifecycle Maintenance Cost Index | 100% | 85% | 35% | 25% |

| Corrosion Rate in Salt Environment | 0.5 mm/year | Reinforcement fails | Negligible | None detected |

| Failure Mode | Sudden yield | Brittle fracture | Progressive delamination | Predictable deformation |

These properties explain why industries transitioning to FRP structural members report 90% reduction in corrosion-related repairs and extended service intervals from 5-7 years to over 20 years before major inspections. The ductile failure profile provides critical safety advantages, with strain capacities exceeding 4% compared to steel's 1% maximum elongation.

Manufacturing Landscape and Product Differentiation

Leading producers offer distinct approaches to structural FRP fabrication. Pultrusion specialists dominate standardized profile manufacturing, with production speeds exceeding 2 meters per minute for constant cross-section shapes. Reaction injection molding serves more complex geometries like connection nodes and custom junctions. Significant variation exists between manufacturers' resin formulations:

Premium producers utilize vinyl ester backbones enhanced with nanosilica, improving compressive strength by 40% compared to basic polyester formulations. Structural fire protection ranges from 60 minutes for standard laminates to 120 minutes in advanced systems incorporating ceramic microspheres and intumescent coatings. Manufacturers seeking UL certification implement rigorous quality procedures including automated ultrasonic flaw detection on 100% of structural sections.

Leading European fabricators produce cellular FRP decks with compression molding for superior surface consistency, while North American suppliers specialize in large-scale pultrusion for beams up to 24" depth. These technical specializations create complementary product ecosystems across geographic markets.

Engineering Custom Structural Solutions

Project-specific design conditions demand tailored material engineering approaches. For a Texas oil refinery project, engineers developed glass transition temperature formulations exceeding 165°C to withstand process heat in fractionation columns. Coastal infrastructure projects utilize specially developed ultraviolet stabilizers preventing resin matrix degradation below critical thresholds despite constant solar exposure.

Structural designers leverage finite element analysis to optimize fiber orientation, significantly increasing stiffness in high-moment regions without adding mass. Connection technology represents a critical development area, with proprietary mechanical couplers achieving 98% load transfer efficiency between members. These technical collaborations between material scientists and structural engineers create application-specific solutions unattainable with conventional construction products.

Demonstrated Applications in Critical Infrastructure

The Gold Coast desalination plant showcases performance capabilities with its extensive FRP structural framing system that withstands salt spray concentrations exceeding 15,000 ppm. More than 80 tons of structural shapes support mechanical equipment without experiencing the deterioration observed in the facility's steel walkway supports requiring biannual maintenance.

Transportation infrastructure increasingly relies on these advanced composites, exemplified by the Canadian National Railway bridge replacement using FRP girders. The installation reduced construction duration by 50% compared to steel alternatives and eliminated the cathodic protection system required on adjacent metallic structures. Municipal water authorities report similar advantages, with Philadelphia adopting fiberglass structural members exclusively for new pump station construction.

Implementing Advanced FRP Structural Systems

Successful deployment of structural FRP profiles requires addressing installation nuances. Unlike conventional building materials, FRP structural members have different handling protocols – lifting straps must avoid edge abrasion and bolted connections require controlled torque application. Material certification remains essential, with ACI 440 and ASCE structural design standards providing comprehensive compliance frameworks.

Research initiatives continue advancing material capabilities, particularly in fire engineering where reactive chemistries yield fire resistance durations exceeding regulatory requirements by 80%. The next generation of structural FRP fiberglass composites incorporates recycled polymers while enhancing mechanical properties, addressing sustainability concerns without performance tradeoffs. These developments reinforce FRP's position as the material of choice for structures requiring extended service life in demanding environments.

(structural frp)

FAQS on structural frp

Q: What are FRP structural profiles and their common applications?

A: FRP structural profiles are lightweight, corrosion-resistant components made from fiber-reinforced polymers. They are used in construction, bridges, and industrial structures. Their durability and design flexibility make them ideal for harsh environments.Q: How does structural FRP fiberglass differ from traditional materials like steel?

A: Structural FRP fiberglass is lighter, non-corrosive, and requires minimal maintenance compared to steel. It also resists chemical degradation and has a high strength-to-weight ratio. These properties reduce long-term costs and extend service life.Q: What types of FRP structural members are available for construction?

A: Common FRP structural members include beams, columns, gratings, and panels. They are engineered to replace or reinforce steel, concrete, or wood. Custom shapes can be fabricated to meet specific project needs.Q: Why choose structural FRP for corrosive environments?

A: Structural FRP resists moisture, chemicals, and salt, unlike traditional materials. This makes it perfect for wastewater treatment plants, marine structures, and chemical facilities. Its longevity in harsh conditions reduces replacement costs.Q: Are FRP structural members cost-effective for large-scale projects?

A: While initial costs may be higher than steel, FRP saves money through reduced installation labor and minimal maintenance. Its lightweight nature lowers transportation and handling expenses. Long-term durability further enhances cost efficiency.-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025