loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

jan . 25, 2025 05:22

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

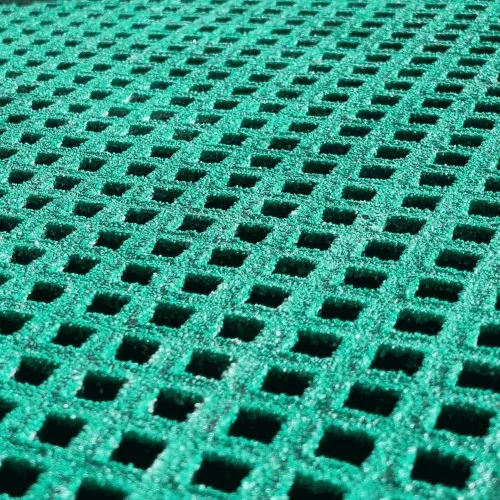

Fiber-Reinforced Polymer (FRP) channels have rapidly garnered attention across various industries due to their distinctive advantages and intricate applications. Comprising a blend of polymer resins and fiberglass or other reinforcing fibers, FRP channels have redefined the standards for durability, corrosion resistance, and versatility in construction and industrial uses.

An often understated aspect of Fiber-Reinforced Polymer channels is their electrical and thermal non-conductivity. For industries dealing with high-voltage equipment or temperature-sensitive operations, the non-conductive nature of FRP channels provides an inherent safety feature. This prevents unnecessary risk of electrical hazards or thermal transfer, making it a preferred material in the electrical and electronics sectors. Environmental sustainability is not just a trend; it has become an essential tenet in material selection. FRP channels score highly in this regard, as they are often manufactured with recyclable materials, reducing their carbon footprint. The long lifespan of FRP channels means less frequent replacement cycles, contributing to less environmental waste over time. In terms of real-world applications, industries have embraced FRP channels for uses ranging from infrastructure reinforcement to equipment support frames. Engineers cite case studies in sectors like oil and gas where FRP channels have excelled in supporting off-shore platforms, showcasing their ability to withstand relentless waves and corrosive sea conditions while maintaining structural integrity over extended periods. In conclusion, the decision to utilize FRP channels is driven by a combination of technical benefits and practical applications. Their adoption across multiple sectors underscores their adaptability, reliability, and cost-effectiveness. For project managers and industry specialists aiming for materials that offer longevity and versatility while reducing the environmental impact, FRP channels represent a forward-thinking choice that meets and often surpasses contemporary engineering demands.

An often understated aspect of Fiber-Reinforced Polymer channels is their electrical and thermal non-conductivity. For industries dealing with high-voltage equipment or temperature-sensitive operations, the non-conductive nature of FRP channels provides an inherent safety feature. This prevents unnecessary risk of electrical hazards or thermal transfer, making it a preferred material in the electrical and electronics sectors. Environmental sustainability is not just a trend; it has become an essential tenet in material selection. FRP channels score highly in this regard, as they are often manufactured with recyclable materials, reducing their carbon footprint. The long lifespan of FRP channels means less frequent replacement cycles, contributing to less environmental waste over time. In terms of real-world applications, industries have embraced FRP channels for uses ranging from infrastructure reinforcement to equipment support frames. Engineers cite case studies in sectors like oil and gas where FRP channels have excelled in supporting off-shore platforms, showcasing their ability to withstand relentless waves and corrosive sea conditions while maintaining structural integrity over extended periods. In conclusion, the decision to utilize FRP channels is driven by a combination of technical benefits and practical applications. Their adoption across multiple sectors underscores their adaptability, reliability, and cost-effectiveness. For project managers and industry specialists aiming for materials that offer longevity and versatility while reducing the environmental impact, FRP channels represent a forward-thinking choice that meets and often surpasses contemporary engineering demands.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025